All Activity

- Past hour

-

Actually I just noticed feed dog seems to be bent on that pic... Maybe it is and I should buy a new one before trying any other ajustement !

-

@friquant thank you so much ! @AlZilla true, I confirm and cheked. I added a picture with needle plate in position showing that issue clearly comes from feed dog placement

- Today

-

Thanks, I guess I'll have to give it a try.

-

Just got a Consew 255RB. It needs an oil pan.

Stagesmith replied to Stagesmith's topic in Leather Sewing Machines

There is an oil reservoir in the top of the machine. Running the machine feeds oil through multiple internal lines until it drips off the bottom of the machine. It really is an industrial machine. -

Butterfly steaks from the tenderloin, or round steaks for dinner tonight?? Oh, nice Machete and scabbard:)

-

Same here. Weldwood contact cement. Do have plenty of good ventilation when using.

-

Choosing durable dog collar thread... linen, Nylex etc...?

DieselTech replied to LakeOtter's topic in Sewing Leather

I myself would use a UV treated polyester thread in 277 or 346 size. I think you can even get it in waxed version. -

I use the red can Weldwood for most projects. It is good for most applications. I also use wood glue Titebond or other brands for some other things.

-

I use good fashion contact cement. I don't think the brand name really matters much. What I have found that bests works for me and gives me the best holding is to apply one coat on the flesh (fuzzy) side of the pieces, let dry then add a second coat until dry (about 10 -15 minutes), mate the two pieces, use a roller to evenly press the pieces together, clamp or weight down the pieces and let sit for 12-24 hours. My theory is the first coat of contact cement sinks into the fibres and binds them together. The second coat holds both surfaces permanently together. I have found sometimes with only one coat of contact cement the two pieces can be pulled apart. kgg

-

That's a great looking case (scabbard? Sheath? Bladeprophylactic?) Kidding aside, I haven't used a machete, but it looks pretty awesome too. More often in my experience, axes or hatchets are used. They may not be legal in Australia, but I think we can still have them in Canada and parts of the UK

-

That weldwood contact cement is pretty much all I use. Even a couple odd projects that didn't get sewn after gluing it holds. The trick like alot of other glues is the set time before sticking pieces together. Spread it on both pieces that's going together and let it set for 20 minutes or so till it doesn't even really feel tacky anymore. Then you want be able to pull 2 pieces apart without damage. I buy it by the gallon from lowes or home depot home improvement stores. It's cheaper in store then most places online.

-

Newer to leather working and work as a Firefighter paramedic. One of my goals since I started in this field was to make my own fire shield and finally got to do it. For next time I’ll raise the screw holes so it fits more snug to the helmet brim but there is always room for improvement. One question I have I decided this time to paint the shield black with my airbrush and Angelus leather paint and sealed it with acrylic resoline one things I’m worried about is the durability of the paint if it will end up scratching easily or not. I also understand it being I’ll take heat and abuse due to my job but want to try to best protect it for longevity and having a better end product. The leather weight I used was 15 ounce. Thanks for any help or advice

-

Your branch of the SCA is the bestest resource. I used to use archaeologists reports for ideas and draw my own patterns from them. I also used to use Olaf Goubitz book 'Purses in Pieces', 'Shoes and Pattens' by Grew, 'Scabbards' by Cameroon, 'Knives and Scabbards' by Cowgill, and an SCA publication on making shoes The SCA used to have hundreds of patterns for items on a website. All free to down-load. I've been out of it all for 20 years so I don't know if it still exists. Ask at your local branch

-

I use contact cement all the time for gluing my leather projects.

- Yesterday

-

Hello and thanks in advance. I have more tooling practice, by far, than sewing, and so I'm studying two handed saddle stitching, got a pony, etc. I just want to chose a saddle stitching thread that is practical for durable use on H. Oak veg tan butt dog collars I'll be concentrating on, and trying to eventually get a few into the local tack shop with tooled designs. And I'd like to get used to what I'll continue to use, up front, and not start all over, soon, with how something behaves. I have been looking at saddle stitch info... Al Stohlman was back in the day and, even today, Jo H. is purposefully traditional. These sources recommend non-waxed linen thread, because they recommend not waxing the ends so that better ends can be made But what about my modern options like the awesome sticky thread mentioning Nylex in passing? Synthetics sound durable, and I've seen a burner tool... maybe that helps with "proper ends" in this manner? I just want a reliable product; I don't thing my customers will care if it's synthetic. The main feature is some hand-tooled designs and custom lettering. Thank you for your thoughts (or links) on pros and/or cons of threads, pre-waxed or otherwise. Jeff, Silver Springs FL, Ocala Forest

-

Ray Allard joined the community

-

Has anyone thought about using formica construction glue for leather projects? https://www.amazon.com/00271-Weldwood-Original-Contact-Cement/dp/B0006MXRY8/ref=pd_sim_d_sccl_3_1/147-4836112-0706438?pd_rd_w=2UpNv&content-id=amzn1.sym.3a852a98-d65f-4301-9bd0-9b589b14d1ef&pf_rd_p=3a852a98-d65f-4301-9bd0-9b589b14d1ef&pf_rd_r=WJZQ74S5S0KPDW4F7P4X&pd_rd_wg=EB4bj&pd_rd_r=362984e1-6bb4-4088-b07b-c23adb755617&pd_rd_i=B0006MXRY8&th=1 It sure is a lot less expensive than what Ive been buying now that infation is effecting my leather glue prices.

-

Nice looking caps, Dano, I can see where hand stitching those could be a chore! My beard was that colour once, now it's sort of white.

-

Good job Chuck, looks the goods. Deer in the front yard, that's a bit different, all I get is the odd rabbit and koalas using it as a thoroughfare to get from tree to tree. As an aside machete's have just been banned in South Australia, they are now a prohibited weapon. Buggered if I'm handing mine in, I'm going to shorten the blade with an angle grinder so it's no longer a machete and use the off-cut to make some small blades.

-

Hello! I've recently decided to try and get back into leatherworking again. I'm most interested in medieval/historical projects, as I am in the SCA. Things like bags, pouches, shoes, maybe some scabbards? Though with modern tools and dyes available. Anyone know of good patterns for medieval projects, especially in the realm of bags/pouches and shoes? I already plan on buying Period Patterns 93, but one can never have too many resources. Also, if anyone knows of any folks who do teaching, or leatherworking groups in central New Jersey, please let me know - I've done some searching but have come up empty (I know there's a Tandy in NJ, but it's nearly an hour from me).

-

I agree with the others. To add, pics will help a lot too

-

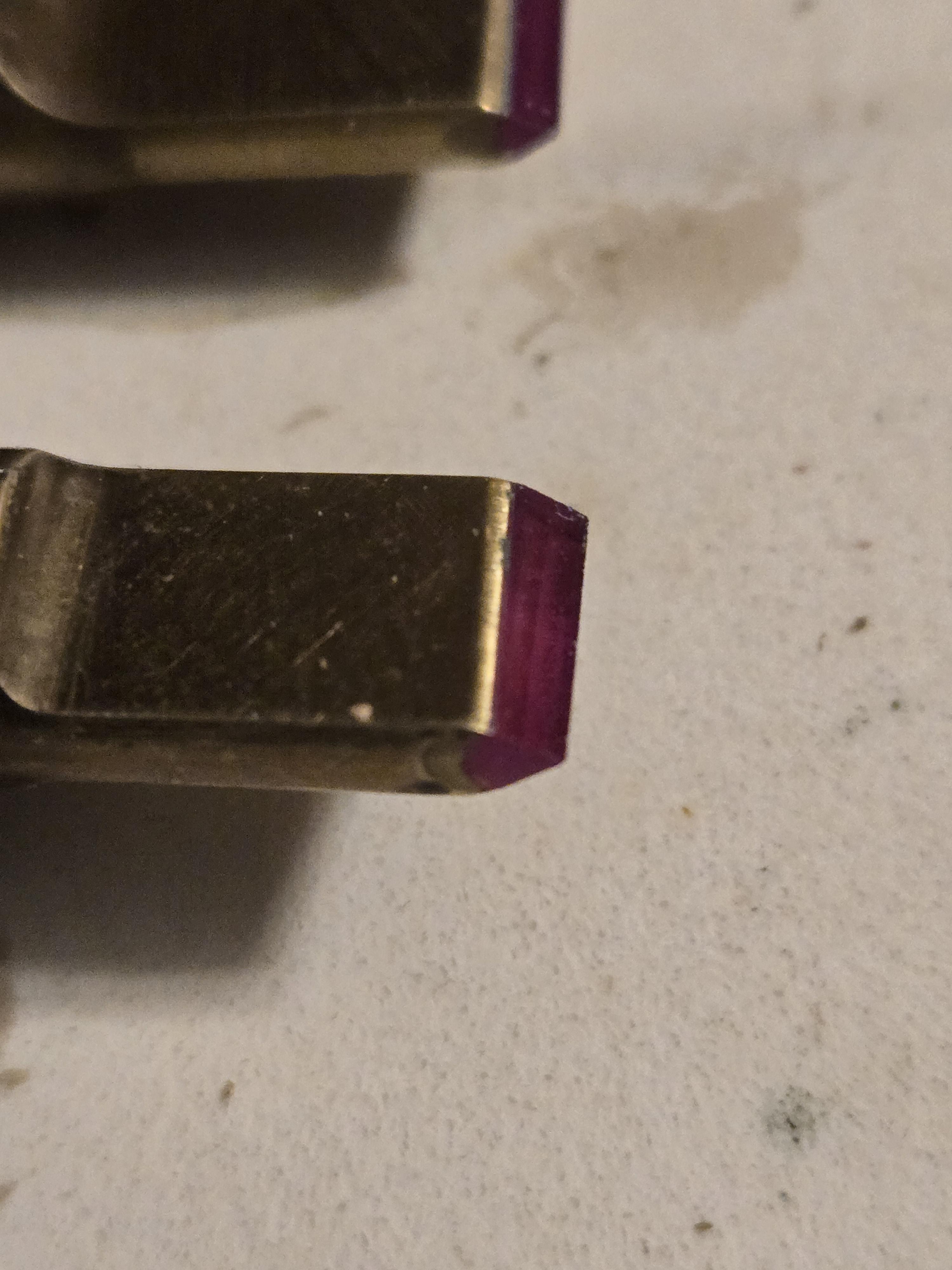

I know this conversation was a year ago but i need dome help. How much are original ruby blades worth? I have three i am wanting to sell and I have seen them on ebay going for 150-200 and up for one or two blades etc. Id like to think they are vintage, and a great high end swivel knife blade is $35 a piece and Tandy sales a synthetic ruby for $100 each. I have two original regular sized and one narrow angled blade with an original swivel knife that is very smooth! 20250928_124726.mp4

-

And there is the answer to my question! Thank you KGG, I doubt I would have found the answer on my own. — AZR

-

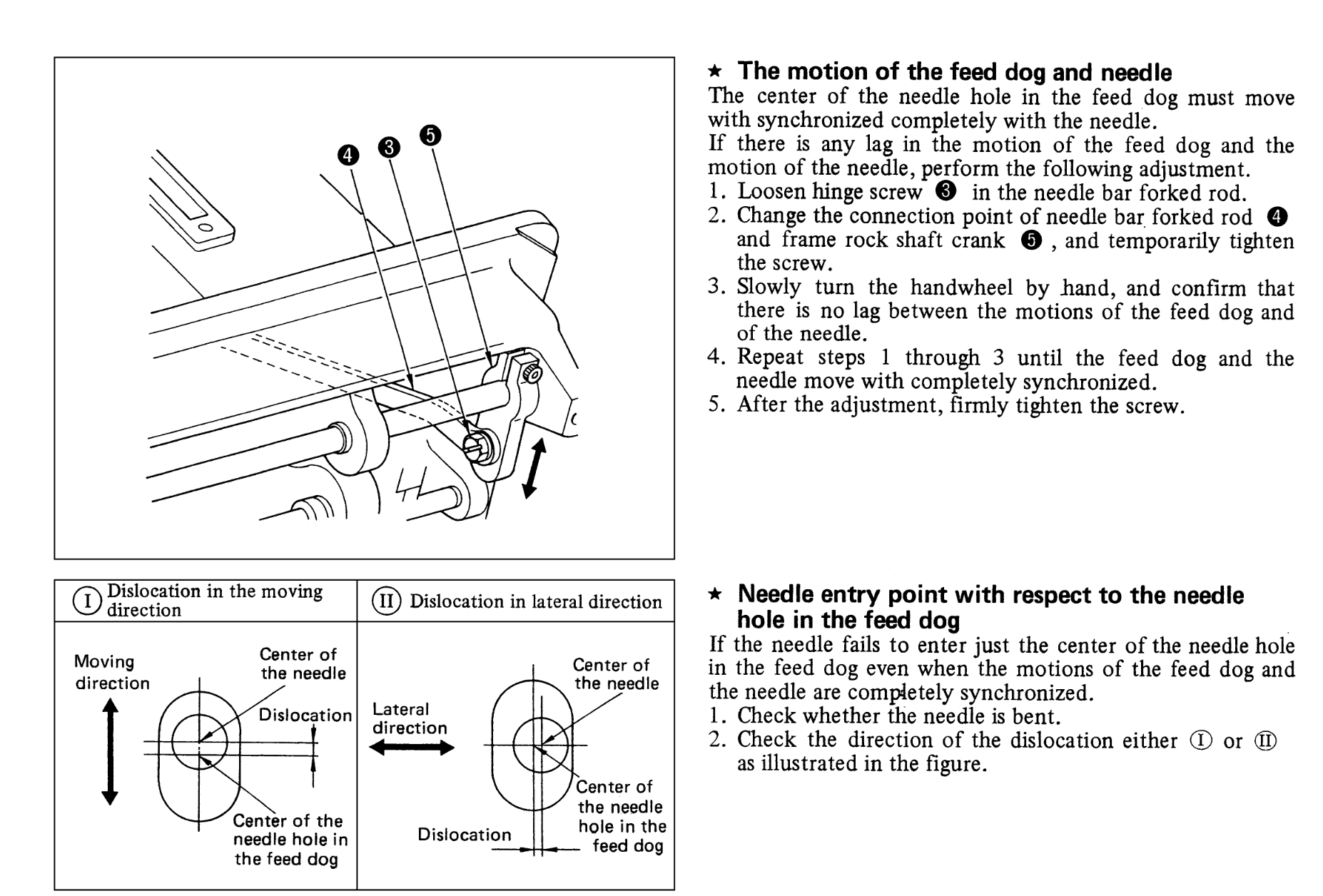

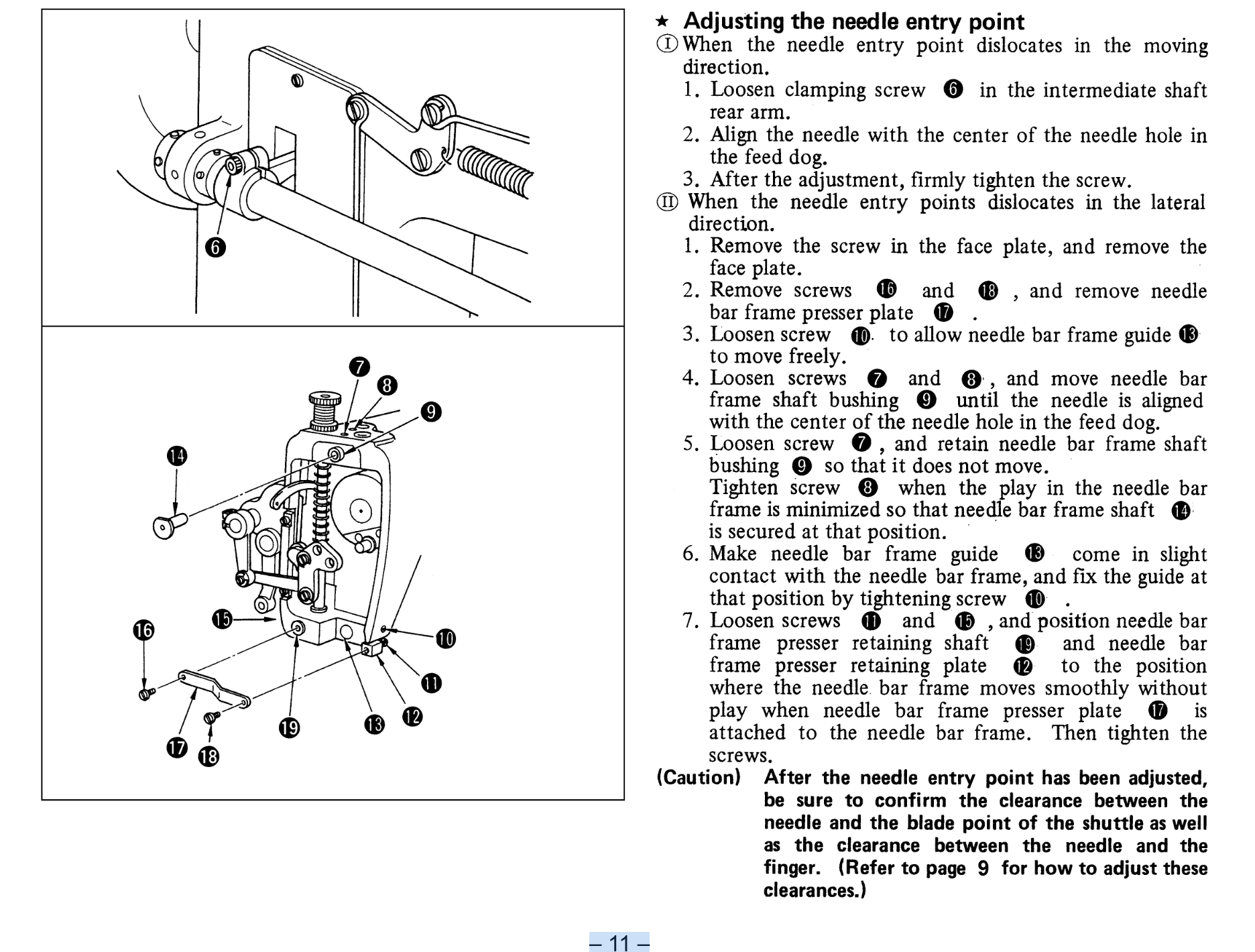

There shouldn't be any lateral adjustment on the feed dog because it would then rub/hit the needle plate. The needle should be centered in the foot and needle plate.

-

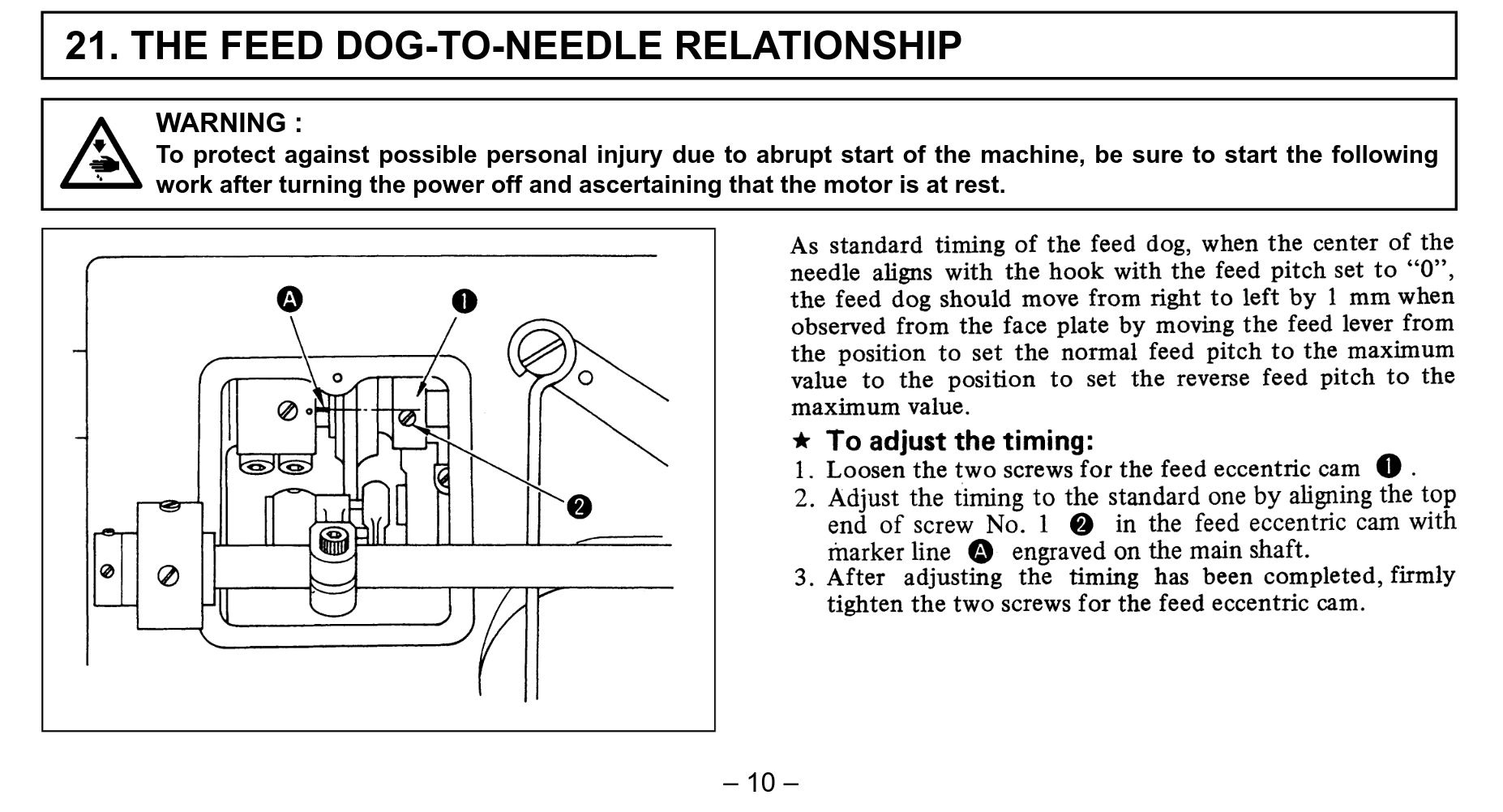

Here a link to a manual for a Juki 243: https://www.manualslib.com/manual/1638502/Juki-Tnu-243.html Section 21 (pages 10 and 11) discusses adjusting the feed dog to needle relationship.

-

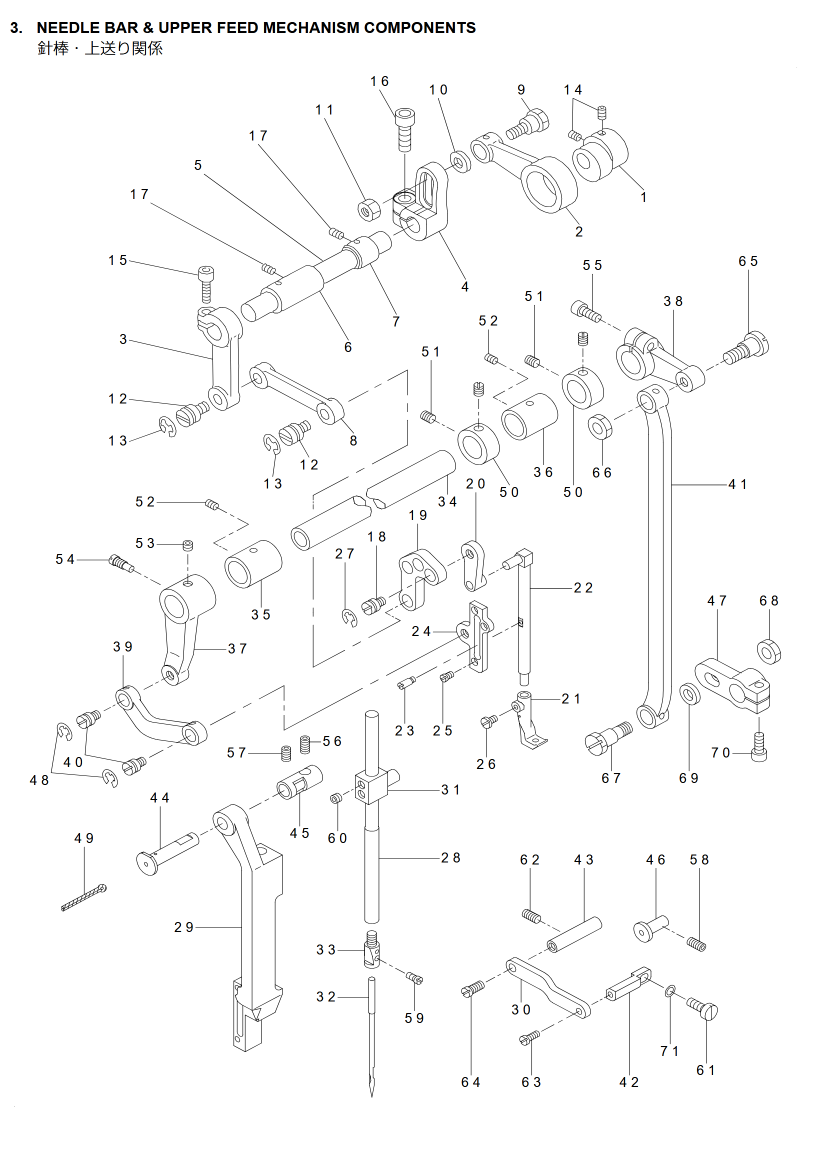

On my machine (Pfaff) you set the needle into the centre of needle hole in the feed dog by moving the needle bar frame. This is the upper assembly that includes needle bar and upper feed mechanism. By my machines is always annoying to get some movements. How is this solved by Juki I rerally don't know. check on which axe the needle bar is hanging, is there and screw that you can loose, and than by rocking the wheel you push the whole assembly slightly to the left.

.thumb.jpg.327685d8c1787fa894323fed9a6b2dac.jpg)