All Activity

- Yesterday

-

Problem with leather splitter/skiving machines

Dwight replied to Coloradoguy's topic in How Do I Do That?

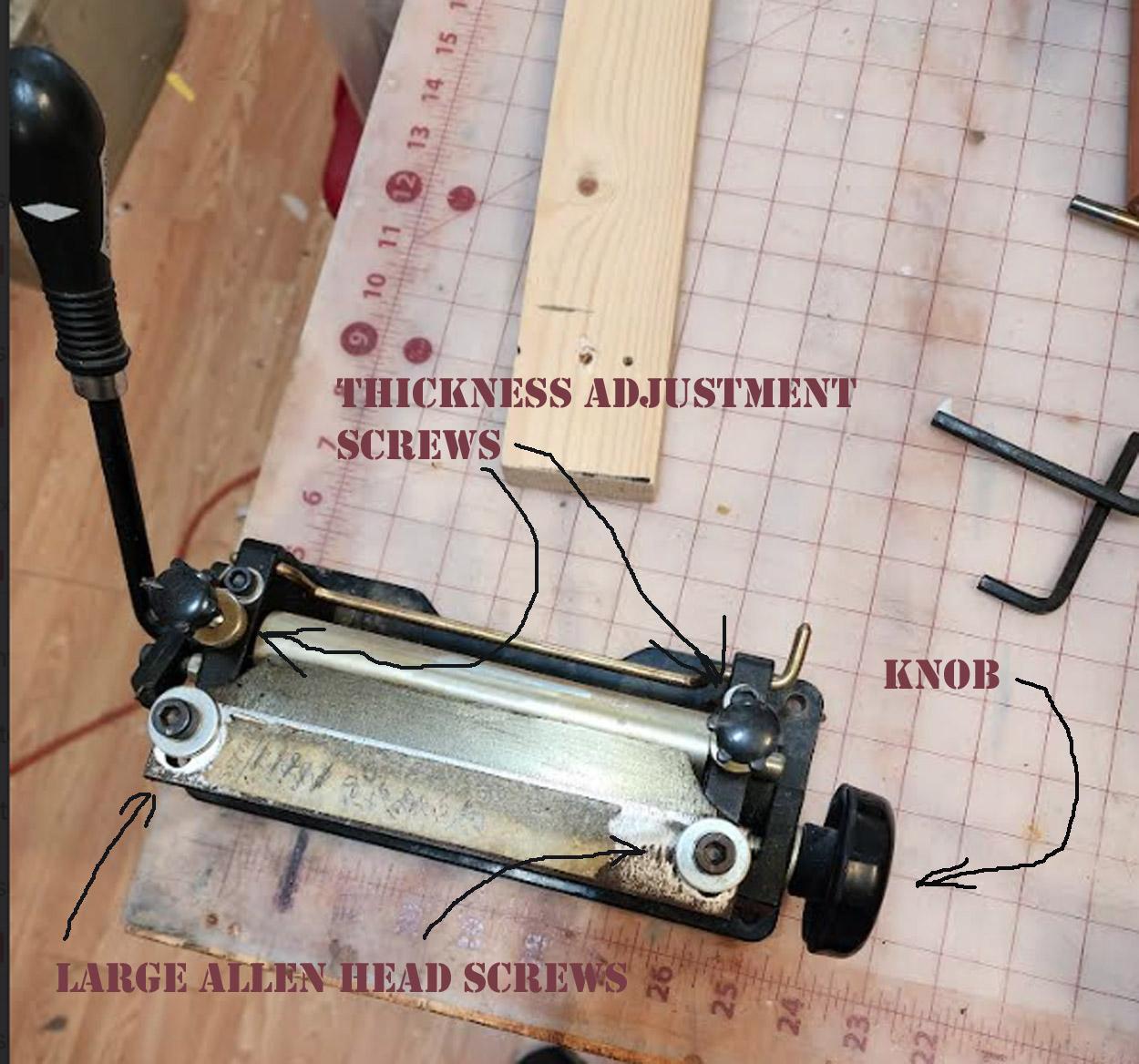

Well . . . to start from the beginning . . . first determine how thick you want this piece of leather to be. Then loosen the large allen screws on each side of the blade . . . then by turning the black plactic knobs . . . you can raise or lower the blade . . . and when you have it where you want it . . . tighten the large allen screws. Now you are ready to go. Loosen the knob on the right side of the skiver . . . and you can then use the lever to lift or drop the roller . . . drop it and insert the leather piece you want to skive. Pull thru about an inch or two while holding the lever down. You will notice it drop as you begin your cut . . . as it pulls the roller up to the proper position. Once you have that inch or two skived . . . tighten the knob on the right hand side of the machine . . . while holding the lever down . . . that will keep the thickness even. You can then lay a board or something on the bail . . . to keep it from allowing the leather to jump up . . . jumping up gives you the bad skiving experience. Pull the whole piece thru . . . loosen the knob . . . insert the stub end . . . about an inch or two from where you need to start . . . again under the bail . . . and tighten the knob . . . pull the stub end thru and you are done. May God bless, Dwight -

Others have probably tried this already but since I discovered it new for myself, I thought of putting it up here. I use thick leather splits as punching mats. I often also use a block of wax. I sometimes place the split piece on the wax block so that even if the punch goes through, it just gets lubricated with wax. When I was last melting the wax block to smoothen it, I dipped the leather split piece in the melted wax. I let it absorb for a minute or two on both sides and then kept it aside to dry. It dried hard, harder than the original split and it works well as a punching mat. For the wax, I used a mix of paraffin wax and beeswax. Plain paraffin is too brittle and pure beeswax is too sticky. Together, they work well for me, both in block form as well as in the punching mat.

-

mikejw started following Leather Coaster Material

-

I recently made some leather coasters as giveaways for a booth. My initial plan was to use a budget-friendly raw veg tan side glued to cork coasters, but getting the edges perfectly flush seemed impossible. I eventually settled on gluing a split to the raw veg tan to get the thickness I needed. My process ended up being: rough cutting both leathers, gluing them, dyeing, burnishing the flesh side, die-cutting circles, and finally, stamping. I'd like to simplify things to: die-cut the leather circles, then stamp the pattern. To make this happen, I need leather that's already dyed, has a reasonably smooth flesh side, takes a stamp well, and darkens where stamped for good contrast. I'm looking at bridle and harness leather. Does anyone have recommendations on which might be better for this application? Also, what weight of leather would you suggest for coasters? Any advice would be greatly appreciated! Thanks in advance for your insights.

-

dikman started following Art Block?

-

Not "art block" (although I'm not particularly artistic anyway) it's more a lack of motivation. I just can't seem to get going.......

-

Thanks for clarifying, Johanna!

-

mikejw joined the community

-

Johanna started following Lost edit button

-

I don't care who you voted for or what you support. The CFM section is not for "conservatives". The "C" is for "controversial" which was what that whole forum turned into instead of leather conversation. There are a dozen people with access, and it doesn't show to anyone else.

-

Problem with leather splitter/skiving machines

Coloradoguy replied to Coloradoguy's topic in How Do I Do That?

Thanks for the tips Dwight. I don't recall reading anything in the instructions about holding the bail down. It's been over a year since I tried those machines and there are two more things I could have been doing wrong. What am I supposed to do regarding locking the knob on the side, and whether I should put pressure on the lever, or not? -

Renia Colle de Cologne vs Syntic Total a Superfix

kgg replied to Yukonrookie's topic in How Do I Do That?

Now that is north. You do need good tough gear and a couple extra pairs of woolies. kgg- 20 replies

-

- contact cement

- glues

-

(and 1 more)

Tagged with:

-

Renia Colle de Cologne vs Syntic Total a Superfix

Yukonrookie replied to Yukonrookie's topic in How Do I Do That?

@kgg I couldn’t have said it better. I’m located in the yukon. 650km north of Whitehorse. It’s rough, mountainous bush country. I live in the middle of it with the closest neighbour a looong ways away. Trails out here are either made by myself or animals. It’s a hard life on gear. It’s something I have to always vividly explain for most people to realize that it’s something to constantly consider when choosing the right gear and that wear and tear is at completely different levels here.- 20 replies

-

- contact cement

- glues

-

(and 1 more)

Tagged with:

-

Renia Colle de Cologne vs Syntic Total a Superfix

Yukonrookie replied to Yukonrookie's topic in How Do I Do That?

What is your opinion of high quality linen thread like, say, a fil a chinois? I’m sure with enough hard use no thread would stand up for eternity, but maybe when hard use is paired with proper care and maintenance? I guess that may answer my question. I’m sure you came across good Lin cable back than too. Interesting, I have heard this since I started the hobby, but I used to be of the belief that dubbin or an natural oil like “pure” beats food oil would do exactly the opposite and protect natural plant or animal based stuff. Thinking that ‘If good for leather it should be good for linen, cotton or flax as well’. I know better now, but my point is that the majority of folks out there still believe this. Now this IS news to me. I’ve been using sno seal on my boots and saddles for ages. Since starting the hobby I’ve even been putting it on sheaths and belts as well, as long as I didn’t stamp much. Making sure I melted it nicely. I don’t think sno seal is only beeswax. Obviously I’m only talking for veg tanned leather, the odd time oil tanned but not chrome tanned. I heard and read that beeswax for chrome tanned is no bueno. Is this correct? I have on occasion used pure mink oil but only on anything where I didn’t mind a “softer” leather. But when I use mink oil, not too much, over the years it softens the leather up too much for my taste. May be just my imagination? Although, I use it a fair bit on my saddles. When it’s supposed to be soft or I want it to become soft, right? For my mountaineering boots especially I found sno seal to be superior to anything else I ever used. I’m talking about good quality triple stitched boots here. They have oil tanned Juchten leather. They’re a completely handmade boot by Hanwag called the “Sepp 100”. Initially pricey boots ($750 US) but they have lasted me 10 years already and been re-soled 3 times. My previous pair lasted me 12 years before I got a new pair, but I now wear them for reall messy work. Mountaineering or riding boots are all I wear and both would be considered work boots for me, as I’m a wilderness guide. My riding boots, usually of the “packer boots” variety, don’t see wear and tear as heavily as my mountain boots. Those will go through hard dry rocky country and plus 30 degrees Celsius one day, swamps and countless creek crossings the next and snow and ice the next day again. Sometimes all in a single day. Plus they get exposed to up to -55 Celsius during winter. I don’t wear them then but they are stored in buildings that aren’t heated when I’m not around for more than a couple days. The boots actually came with 3 vouchers for free re-sole. So my next re-soling will be the 1st one I gotta pay for. The soles for my mountain boots are usually down to 40% life after 2 years. So going with them, while initially sounding expensive, is actually economically sensible. Well put!- 20 replies

-

- contact cement

- glues

-

(and 1 more)

Tagged with:

-

Okay. I'll try that. Thank you.

-

On Google, use site: leatherworker.net followed by your search parameters

-

Dwight started following Problem with leather splitter/skiving machines

-

Problem with leather splitter/skiving machines

Dwight replied to Coloradoguy's topic in How Do I Do That?

I use my Tandy splitter almost exclusively for belts . . . generally I leave a little extra on each end . . . I grab it with a pair of vise grips . . . and pull it thru. I actually start about 10 or 12 inches in from one end . . . then turn it around and do that section last so the whole blank is the same thickness. You are probably having two problems . . . The first is your blade is not sharp. Coming from the factory . . . none of those blades are SHARP . . . they are kind of a dull sharp . . . but not sharp type sharp. Your blade should be able to be held in one hand and shave 1/2 inch slices of a piece of copy paper . . . just like you might do with a straight razor or a pocket knife. If it is not that sharp . . . you need to work on it. I sharpen mine with several stones . . . ending up with a 3000 grit . . . and then I strop it . . . and I strop each side. When I get done . . . you do not want to touch that blade for any reason except to cut leather. Your second problem is in the picture . . . my hand it on the bail. Your leather needs to be under that bail . . . and as you pull the leather thru with your right hand . . . hold the bail down with the left hand . . . or lay a 2 x 4 edge on it to keep it down. If you don't . . . your leather will ride up and you will cut completely thru your blank. If you take a good look at the picture . . . my blade will appear to be rusty . . . it is not . . . believe me. It is greasy . . . that is just plain old axle grease on it . . . and it is on both sides . . . it keeps the sharpness from going away between uses. I wipe the grease off the blade . . . then run a piece of scrap thru it to check for sharpness . . . before I use it. When I get done for the day . . . unless I know for certain I will use it the next day . . . I grease it up and set it off my work bench. Hope this helps . . . may God bless, Dwight -

larry1096 started following Tippmann Boss for sale in Massachusetts

-

Frodo, I'm assuming it was a aluminum canoe, which would have stood up to hitting any obstacles in the road better than fiberglass? I'm cringing at the thought of doing that to an old canvas and cedar strip canoe, or even a fiberglass canoe! I've seen too many busted canoes! I remember this one long-ago canoe trip where our trip leader had a beautiful brand spanking new 17 ft. Grumman aluminum canoe. This one set of rapids required that you pull hard to the left after going down a small chute/waterfall, to avoid the right channel, which was a rock garden. They hit the chute at an angle, and the canoe flipped. It think they must have hit nearly every darn rock on their way down that right-hand channel. The beautiful Grumman was considerably less new and less beautiful by the time they got through the rapids! One nice thing about aluminum canoes, though - you can generally bash the dings out of it with a rubber hammer or a boot! Oh, the things I did in my younger days...I LOVED canoeing! Don't get me started on stories, or I'll hijack this thread!

-

Coloradoguy joined the community

-

I had major problems with two different skiver/splitter machines. The first one I purchased from Tandy (their High Tech Leather Splitter) as a discontinued closeout. I ruined several leather belts with it while trying to skive the buckle end. I practiced on scrap leather so I thought I had the technique down, but on some belts when I pulled the leather through it skived all the way through the to the face of the belt and ruined the belt. This happened several times. So I sold it on eEbay and purchased a different one on Amazon that looked the same machine as the TandyPro Deluxe Leather Splitter but is being sold for much less. I had the same problem with that unit and returned it. With both units I had to pull very hard to get the leather through. Has anyone else had this happen, or is my problem all user error? I'm thinking about trying either the unit from BuckleGuy or the TandyPro Deluxe Leather Splitter. The BuckleGuy sells what looks like the same unit as what Tandy and Amazon are selling, but in a demo video it appears the leather pulls through his machine very easily. His website says the blade is really sharp.

-

I know people who use a canoe towed behind there snowmobile to haul supplies to there cabin which is only accessible by car 6 months of the year.

-

CFM Conservative Forum Member Hell Man, I am damn proud to be targeted as a Conservative. I do have a request please add a "D" in front of the "C" Deplorable Conservative Forum Member that will make me Smile and feel all fuzzy inside

-

Renia Colle de Cologne vs Syntic Total a Superfix

kgg replied to Yukonrookie's topic in How Do I Do That?

My take is there is no ideal boot thread to cover Canada's widely varying temperatures. Everything from hot humid summers up to about 40 C (104 F) with a humidity factor on top of that temperature while some parts during winter will experience temperatures down to -60 C (-76 F) plus a wind chill factor. In the summer you can only strip down so far as not to scare the horses while in the winter you dress up to look like the Goodyear blimp. I can remember waking up one beautiful sunny winter morning a few years back and no water it was frozen. It was a balmy -50 C and I'm in Southeastern Ontario. Those winter temperatures will play havoc on bonded nylon thread. Since bonded nylon absorbs water during cold conditions like what the Yukon experiences (dropping down to, if I'm not mistaken, -50 C) the thread may act more like that of glass (Glass Transition) of becoming more rigid and brittle. Flexing will then cause fraying / cracking and failure of the thread. In real cold conditions bonded polyester would probably be a better cost effective solution. Kevlar would better again but would probably have other cons besides cost. kgg- 20 replies

-

- contact cement

- glues

-

(and 1 more)

Tagged with:

-

Thanks for the correction North Mount!

-

Yes, that is what I am looking for. Yes. You could start a new thread. With other people adding their knowledge to it, the thread could become informative enough for the moderator to pin it. Otherwise search terms do not always give what one needs. This information might be present in the forum elsewhere but it did not come up with my searches. For some reason, no matter what I do, the searches only show results pertaining to each word, not phrases. And I know how to do searches online but this forum gives me a whole lot of trouble there.

-

Nice work! Tried a laser, can't stand the smell. I do appreciate the detail. I bought a 3d printer, going to try making stamps for that.

-

Johanna already told us it was for the people with access to the political section. But the moderators only give it to people that support Trump. @Northmount @Johanna please take this off my profile and list me as a contributing member or put it on every members profile who had access to that section. Why only Chuck, Frodo Tsunkasapa myself and two others.

-

its funny it's the only title that they won't tell you what it actually means. It makes me feel special LOL.

-

Renia Colle de Cologne vs Syntic Total a Superfix

chuck123wapati replied to Yukonrookie's topic in How Do I Do That?

Not only the proper type of glue but the correct application of the glue is also critical to a good bond. Glueing and sewing in leather work is the same concept as gluing and nailing in woodwork; they work together to make a better and longer-lasting product.- 20 replies

-

- contact cement

- glues

-

(and 1 more)

Tagged with:

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)