All Activity

- Past hour

-

Chompper26 joined the community

- Today

-

Ben Tyson1 joined the community

-

Cactusman started following White - best dye/paint

-

Looking for best way to apply white to leather projects. Generally I am a fan of Fiebing’s Pro dyes… and Leather Dyes. Light colors, they are a challenge. I tried a shoe dye and a light wash, but not happy with the results. Suggestions?

-

TwistedSister joined the community

-

Hi everyone. I am new to leather working (about 2 years) and am wanting to move onto more challenging projects like upholstery. I was able to obtain this REX 381-2 for a good price and was told it was sufficient for this kind of work. I would appreciate if anyone could offer their opinions on this machines performance for leatherwork, and what things I can do to make it better for the task. Thank you! https://imgur.com/gallery/5H2Vro0

-

I feel your pain. Interesting design so the belt is now multilingual. kgg

-

RockyAussie started following Sharp needles not always good

-

In the past I have sometimes polished the tips of my needles to not be so sharp to help stop them cutting threads so much when back stitching or going over threads already in place. On this particular job I was aiming to make a belt that could be worn both inside and out so I wanted to be sure to have a needle sharp enough to not pucker on the bobbin side. The stitching was done on my Cowboy 4500 with a new 160/23 LR Schmitz needle and 138 poly bonded thread. The stitching went very well all the way from the start up to the last four stitches. This resulted in 3 different threads being cut right through as shown in the pics below. My Cowboy machine knows a few new #%^& words now and like my machine I just never stop learning. I started the stitching at the top of this join went around until I got to the bottom to over stitch and the swearing began. Double needles needed to fix came out alright in the end.

- Yesterday

-

I was getting some things on TEMU and had to bring my order over the minimum value amount. Looking around for something cheap and possibly useful I came across these; they are stitch markers for knitters. I got 80 for about 50p (40c ?) They will keep two pieces of leather in alignment for sewing up

-

dikman started following A second generation of long-slide Glock holsters

-

A second generation of long-slide Glock holsters

dikman replied to DeWayne Hayes's topic in Show Off!!

That's a bit different. Why don't you give them a polish? -

LMullins started following WTB: American Straight Needle/Landis 16

-

As the title suggests, I'm looking for a Straight Needle stitcher. also looking for a Landis badge to restore a current machine. Thanks

-

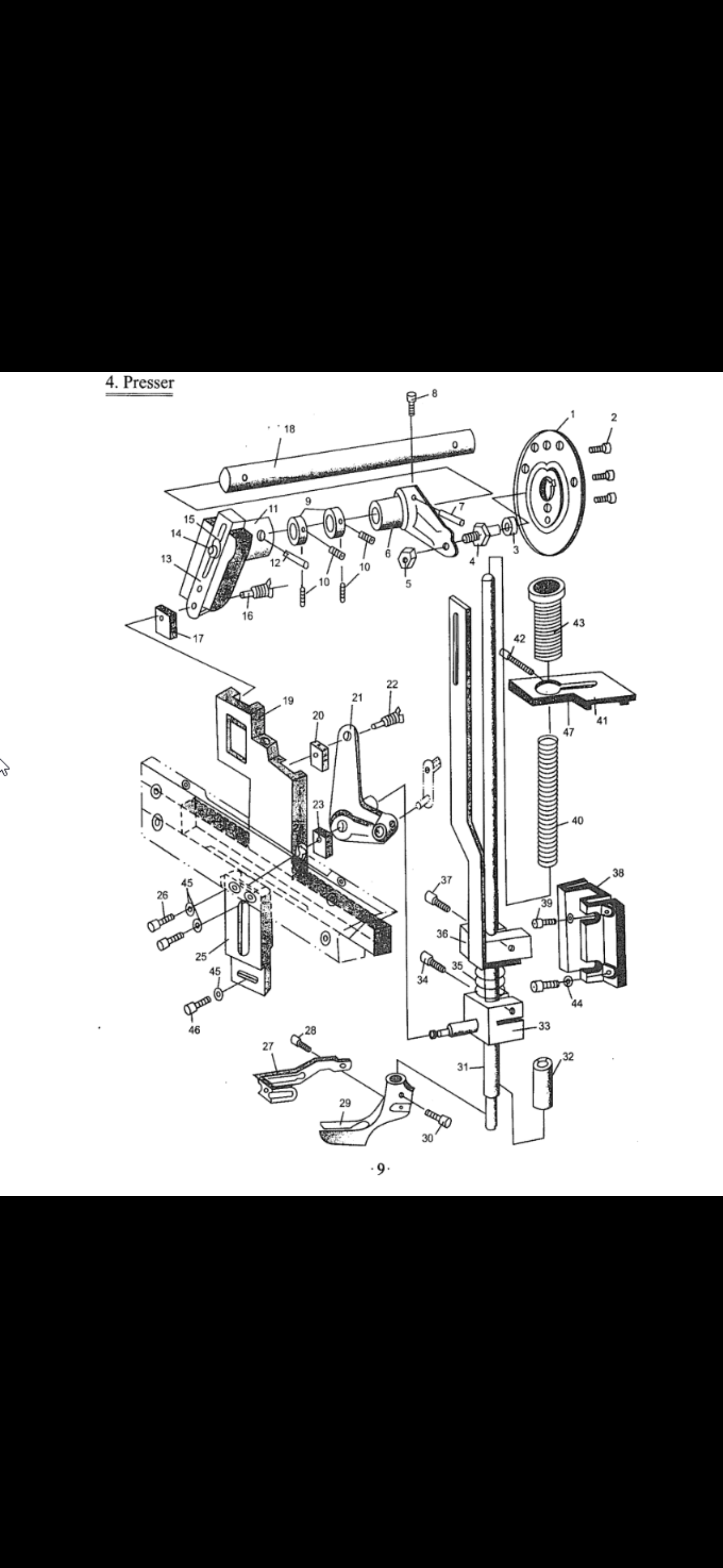

Backstory I had an issue where the presser foot was Stuck in the upright position. I messed with 33 and 36 settings as those were something I found online to adjust. In the end the issue was that 14, a bolt that controls the step height, had come loose and went to a 0 height position. I wasn’t sure which direction to offset it. I tinkered and got the machine running again. Current The machine works but it seems to struggle more than before when getting started. I don’t have the same low speed control I once did. I’m also having the presser foot lift getting stuck after raising the presser foot. The problem gets worse the higher I need to lift it. I can only unstick it by rotating the machine. Obviously not ideal for stitch placement! Also makes it unusable for thick stuff which is what this machine is for. Here is where I need help… What should the factory position of bolt 14 be on the slider? What is the best way to adjust 33 and 36 back to ideal settings? Are there any additional things I should be checking? If you can point me to the information or a idea I would greatly appreciate it. I’m reasonably handy but don’t have any specs for this stuff. Thanks, Tom

-

Kibitz503 joined the community

-

BlackyCatto joined the community

-

Another alternative is find someone with a 3D printer and they show be able to do one up in the size you need. The cost of the actual 3D print would be less then $2.00 in materials but getting the design replicated is going to be costly. kgg

-

-

Dwight started following looking for a specific "basket weave" stamp

-

This idea will not get you thru a dozen belts . . . but it should get you thru 1 anyway. Take a look on youtube . . . making things out of HDPE . . . which is gobbledygook for milk jugs. You can melt the milk jug and put it into a mold you have made that is about 1 inch square and 4 inches long. Once you have that piece . . . cut it with a sander to the correct width and depth . . . then get a set of fine files . . . there's about 10 in the set at Harbor Freight . . . you can use those smaller files to make the lines in the HDPE. If you take your time . . . you should get at least one belt out of it . . . and if the tip messes up . . . sand it off . . . and make another one. OR second . . . find someone who has a laser engraver . . . that is strong enough to cut 1/8 inch steel . . . He should be able to duplicate one for you . . . that will last a long time. One of the keys to being successful in almost any hand work these days . . . think out of the box . . . and be resourceful May God bless, Dwight

-

It's based off of a Seiko CH-8B which are easier to find parts for. They started with those machines and modified the foot lift walking mechanism. I'd download a manual for the Seiko and work off of it. Anything in the Seiko manual that doesn't match your machine was custom made by Ferdinand and I'm not aware of anyone who is making those parts (unless someone has old stock).

-

just measure your current punch with calipers to get the dimensions. Or ask your die maker if they have made anything similar. They may already have something they have created for someone else.

-

We are about 120 miles from the closest Tandy store, and it is the closest leather store to us. I may have to take a drive up there and check them out. I appreciate the help.

-

If the O-ring looks like your usual O-ring (i.e., like a tiny donut), you could go to Harbor Freight and get one of their O-ring packs and see if any of them are close enough. Other than that, you could find a machinist supply company near you and see if they had something there that would fit - just bring the old O-ring with you.

-

@BlackDragon, I didn't realize you could ask for that! Thanks.

-

Wizcrafts started following Where to buy a new machine

-

I have had a Cowboy cb4500 since 2012. I bought it from Toledo Industrial Sewing Machines. One of my best friends bought a Cobra Class 4 in 2011. They have the same capabilities and capacities. We both use these machines multiple times every week; sometimes on a daily basis. As long as you keep them oiled, including opening the left faceplate cover to get to the internal crank shafts, they should keep sewing for decades. Note, that there are many accessories available for both of these heavy stitchers. Most are available from the primary dealers. Others are made by custom shops, like extra narrow feed dogs and throat plates, which allow you to sew narrow straps or thinner work than the original equipment was built for. My buddy and I both have narrow feeders and throat plates and leave them in most of the time. I only restore the originals if I am going to sew something with #346 thread and a #26 needle.

-

If you have a Tandy store nearby, take your punch or belt there and compare the sizes. They have 3 sizes. Maybe these listed sizes might help you.

-

I have been making belts for years using an oval punch to put the small holes opposite the buckle end of the belt. I am looking to have a die built to click them out. The punch I am using is a very old one that does not have the size on it, so I am not sure what size to tell a die maker to use. I make 8 oz to 16 oz belts so the oval holes sort of works well for that range. Since I am not sure what size to advise the die maker, I thought I would ask to see what size other folks that build belts use? Any help would be appreciated. Thanks

-

Dwight, Thanks! And yes, lol! Pastor Bob, Thanks! EVERYTHING I have cut on a laser seems to have terrible fumes. But yes you are right, bad fumes for sure. I typically drag everything outdoors when I use it anyway, but the fumes stay on the laser cutting grid until I pressure was it. Stinks the unfinished basement up quite a bit.

-

Susquehannabum joined the community

-

Pretty slick. I am always leery of cutting chrome tan on the laser. Fumes are really bad.

-

Angry Chihuahua joined the community

-

Agreed! Bob sells Cowboy sewing machines and the 4500 is supposed to be very close to a class 4. I bought my 4500 from him and am very pleased with it and the service. Jim

-

I found a couple on Bruce Johnson's site but the bar looks to be different. Some stamps can be impossible to find because they may be custom made. Trying to copy something so exactly can drive you nuts, trust me I know. People wont notice most of the tiny differences so if you find something pretty close you'll be fine. https://brucejohnsonleather.com/products/stamping-and-carving-tools/basket-stamps

-

Dwight started following Phone Holster

-

That's good . . . the new Bat Masterson . . . lol May God bless, Dwight

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)