All Activity

- Past hour

-

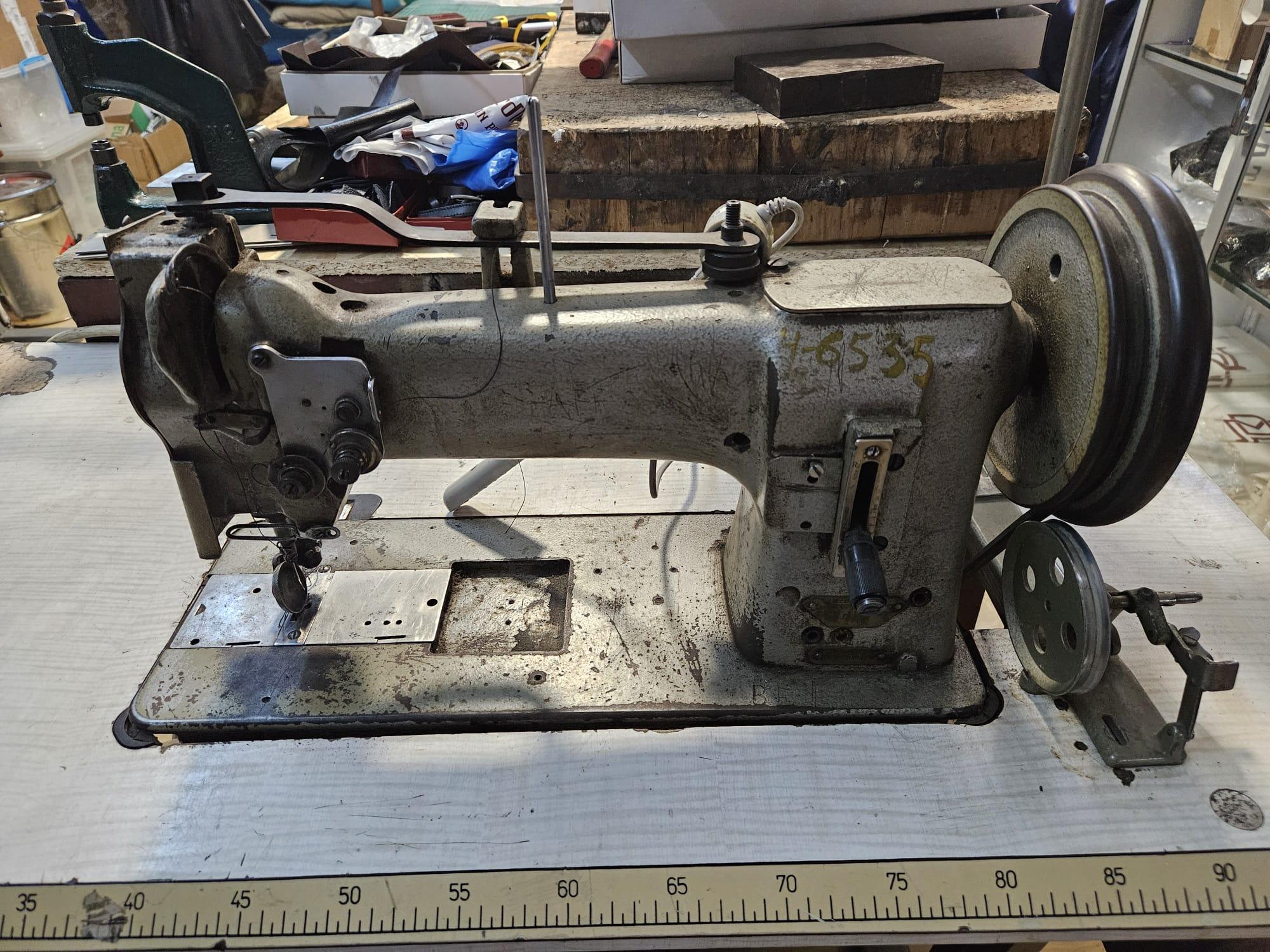

Thanks! I did a bit of paint chipping when I assembled the parts but that's for the patina...intentionally LOL. One thing I forgot mentioning in case somebody wants to add the needle feed. Timing between feed dog and needle is different in both cases. Drop feed = feed dog moves when the needle is out, dual feed= they go together. I want to see also what does it mean to add a larger feed dog, as surface. Such as one from pfaff 142 with dual needles. Because with its original feed dog on 543, the one which is offset to the needle, it feeds ok, but since the needlepushes down there is a small bit of movement on the material. So my intention is to use a dual needle feed dog so the presser wheel sits on the feed dog but also the needle to have some support underneath. In theory it should work. A 545 would solve each issue but since I already have the machine and honestly it stiches really nice. In the video, ticket 15 thread or v207 size up and down and VR 150 size needle. I like VR compared to LR due to 2 more extra cuts. I've added a pic with how the machine looked before. A bit like crap. And I must say the parts are really durable. In terms of age, I dated based on the serial number, in 1955.

- Today

-

Hermann Oak G19 Leather Holster

LMullins replied to LMullins's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thank DieselTech. it's probably worth mentioning, I was always after a deep rich Black color and never really got it with Fiebing's. I used to do a base coat of blue dye, and then fully dry and buff, and then come back with black. This helped get a deeper dye but still not quite what I wanted. I find Angelus tends to apply more evenly and with a deeper color. Just my observation 😎 -

I never said I didn't know how to make them. There's several ways of patterning a holster for a firearm, which I won't be listing here because I could go on and on. Especially for SA Revolvers... I'm simply asking for ways to make the process more efficient and discuss different methods of achieving that goal.. which is a normal part of refining a workflow. That assumption doesn't add any insight to the topic at hand. That’s like responding to a question about better edge finishing by saying someone shouldn’t sell belts if they’re asking.

-

Hermann Oak G19 Leather Holster

DieselTech replied to LMullins's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Nice work! Dye job looks great to. -

Hermann Oak G19 Leather Holster

AlZilla replied to LMullins's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That is some precision work. Very nice! -

- Yesterday

-

I used a trim paint roller on a 2'x 9" piece recently. worked well. My basic theory; larger piece, larger applicator.

-

Been out a while. Knife sheath to get warmed up again.

DwightT replied to DwightT's topic in Show Off!!

Thanks. It's always interesting trying to wet-mold some leather that has already been tooled. At least with a basket weave I don't have to worry about losing too much detail. I was bored a while back so I watched a couple videos by Jim Linnel (Feather Carving) and Don Gonzales (Large Basket Weave). I was intrigued, so I grabbed a piece of scrap leather and gave them both a try. Not the greatest, but it was fun playing with them. Maybe you just need to watch a couple videos and go play. -

Hermann Oak G19 Leather Holster

LMullins replied to LMullins's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thank you. Holsters are one of the few projects where I'll reach for Resolene instead of Tan-Kote, so it always looks a little jarring to me. definitely gives a nice deep color though 😎 -

Hermann Oak G19 Leather Holster

dikman replied to LMullins's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Looks good, very neat work. -

Well done, nice restoration and a serious bit of modding!

-

A good point, the external-mix siphon-feed are better suited to what you want to do as they generally have a wider spray pattern than a double-action internal mix - plus they are cheaper, easier to use and simpler to clean.

-

Hey folks, I've been getting pretty deep into holster making as of late. Lot of orders coming my way, primarily for revolvers. It's not too bad to guesstimate pancake holster stitchlines, but there's gotta be a method I'm unaware of to consistently calculate the distance based upon the dimensions of the firearm. Any good resources dedicated to this topic? Would be interested to know how you folks do it. thanks!

-

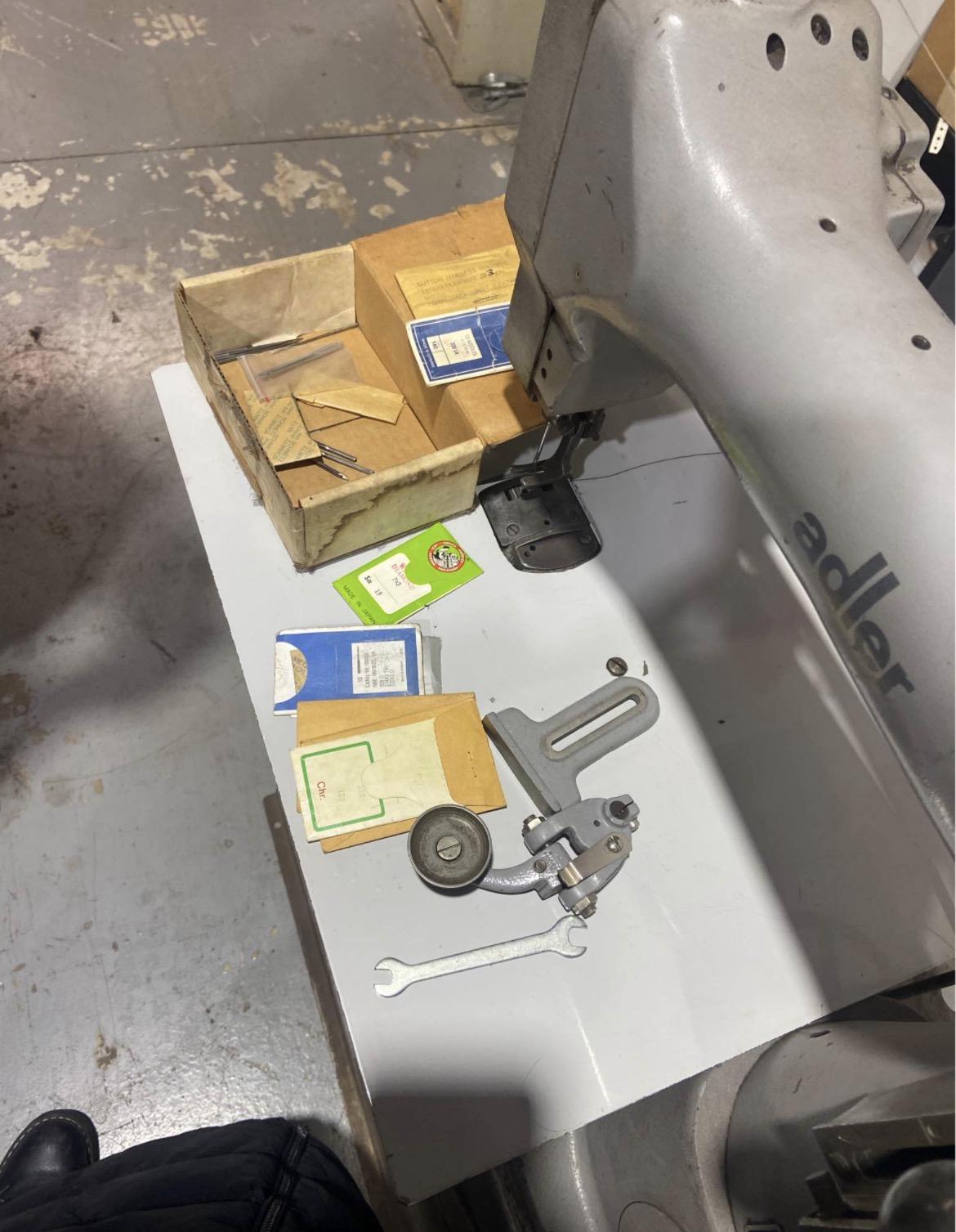

Thanks! Decals are from https://www.singerdecals.com/ I found the majority of parts in my country, Romania. And the 545 parts for the needle feed, I found them on ebay in Poland. https://www.ebay.com/sch/i.html?item=305456329419&rt=nc&_trksid=p4429486.m3561.l161211&_ssn=jerzmerci0 But there is also another guy in Lithuania: https://www.ebay.com/str/sewtech71 I would have loved to buy a 545 but it was over my budget so this 543 I bought it for nothing actually and in my budget, still, I could buy the parts to restore it. Honestly I really like working on these machines. My Adler got the same treatment and now I am having a second Adler 169 that I want to prepare for a buddy of mine.

-

@OscarRush Sewing those thicknesses of veg-tan leather are beyond the scope of upholstery class walking foot machines. You'll need to buy a machine that's built to sew holsters, saddles and horse harnesses. Most of these machines can sew at least a half inch of hard leather. Some, like the cb3500 and 4500 that AlZilla mentioned, can sew 7/8 inch of saddle skirting. I have the 4500 and a bunch of walking foot machines, so I know what I'm talking about. My walking foot machines can sew up to 3/8 inch of chap or garment leather, using #138 bonded thread. My Cowboy cb4500 can sew from just under 8 ounces, up to 52 ounces thickness with very heavy thread, like #441. I personally never go beyond #346, but I could if I needed to.

-

Take bobbin assembly out of 1341 cyclinder arm

TonyD1948 replied to TonyD1948's topic in Leather Sewing Machines

Thank you -

Thumbs-up, Chuck!

-

yes - Adler 105 - 64 subclass, needle feed machine with heavy roller foot!

-

I've also been getting into this weave pattern. I'm having trouble w/ free handing the pattern- esp the spacing to size up for larger weave sections (eg. for a bag panel). I've downloaded the various paper templates but looking for an acrylic one that I've seen w/ the Wuta wallet and others. Any luck by others finding a better template? Thanks much.

-

Fender repair...

Brokenolmarine replied to Brokenolmarine's topic in Saddle Identification, Restoration & Repair

Yup, they do that a lot here as the temps get into triple digits. I've watched a lot of his stuff over the years. Excellent instructor, even via you tube where you can't ask questions. -