All Activity

- Past hour

-

The banding steel isn't hardened but it had no problem punching into the white plastic board in the press so yes, I think the saw would work ok. I looked up those rolling thingies, unfortunately they're not cheap anymore.

- Today

-

I've got one of those sharpened hole saws somewhere. Don't think I've ever used it. That mini rolling mill makes it so easy to do circles. I would have thought that even the soft part of the hole saw would do the job if the edge wasn't so fine to make it fold over i.e a blunter edge. Even mild steel is much harder than leather.

-

Singer 29k1 presser foot doesn't work

MelissaViarengo replied to MelissaViarengo's topic in Leather Sewing Machines

I put the stitch length adjuster as you told me, so now it touches the top of the raised foot. I tried with the same two layers of leather and it still won't work. Then I tried with a piece of knit fabric way much lighter in weight and thickness and the machine transported the fabric very well. Then I tried with a piece of felt, the machine stitched me one stitch transporting the fabric but then it strarted sewing on the same spot as before and only if I applied a bit of pressure pushing the fabric the foot would take it back. I don't know if it just a problem of adjusting the pressure to the material at this point. I would really like to avoid taking apart the head of the machine as I am afraid I won't be able to put it back together. Thank you for the patience -

There is one on eBay that's been there for a while. It's $200.00 but he temporarily lowered the price to $150.00. I offered $125.00 and got no response. But I think he'd take $150.00. Out of curiosity, what stamps do you have to trade? Dale

-

While on the subject here is another restoration . Its an Esto 3 in 1 . Similar to a Landis . When i got it it was seized from being outside for 20 years. I replace it with a new blade and had to make a crank handle for it . As a matter of interest to fellow Esto 3 in 1 owners . The rotary blade i replaced is a new Landis blade . Therefore an Esto round knife / blade and the Landis are interchangeable. I got my blade in Australia from Leffler and sons in Melbourne . The color choice this time was inspired by a Subaroo that drove by . Estos were originally and ugly green but i think i chose one a little more appealing to my eye . The green color of the 3 in 1 and the orange one in the previous post are both auto paints in a candy pearl . The auto paint shop down the road will mix any color i want and will put it in an aerosol can for so i don't have to clean a spray gun between coats . Both machines work perfectly and are in every day use . I believe the orange one is over 100 years old and the green one from the 1950's

-

I forgot about this thread , Here the story. I bought the esto skiver in a previous post from RoToMiMo. I stripped it down to bare bones and went the whole hog. Below is a photo of the finished job. I went full Liberace on the paint job inspired by a Ford ranger that drove by when i was thing about color. I know its a bit out there but why not .

-

I wouldn't say the inside is downright ugly, not at all. It's the inside of a hat, not supposed to be nice. Now the outside? That's b-e-a-utiful! Been making a hat in my mind, never built one with my hands yet. I hope it turns out half as nice as this. Nicely done!

-

Seiko Lsw-8Bl Bias Binding Foot?

Constabulary replied to Oleoleole's topic in Leather Sewing Machines

same as for singer 111w https://www.ebay.de/itm/142635485129 College Sewing or Trojan Sewing in the UK should have them as well EDIT: https://www.college-sewing.co.uk/parts-by-type/single-needle-walking-foot-feet/singer-walking-foot-feet/singer-111w-walking-foot-feet.html?p=3 -

Might depend on the type of saw? I was thinking of the real cheap Chinese ones which are likely made out of plain carbon steel which hopefully would mean it can be re-hardened if necessary.

-

I did that for a 4" hole saw. When you get down to the base of the teeth and sharpen it, you are into soft material. The edge rolls over if you don't come down perfectly square, then have to take more material off and sharpen it again. I guess I should try heating and quenching it to harden the edge. Lots to heat to an even temperature before quenching.

-

It works well. I will remove a number of post that distract from the intent of your post.

-

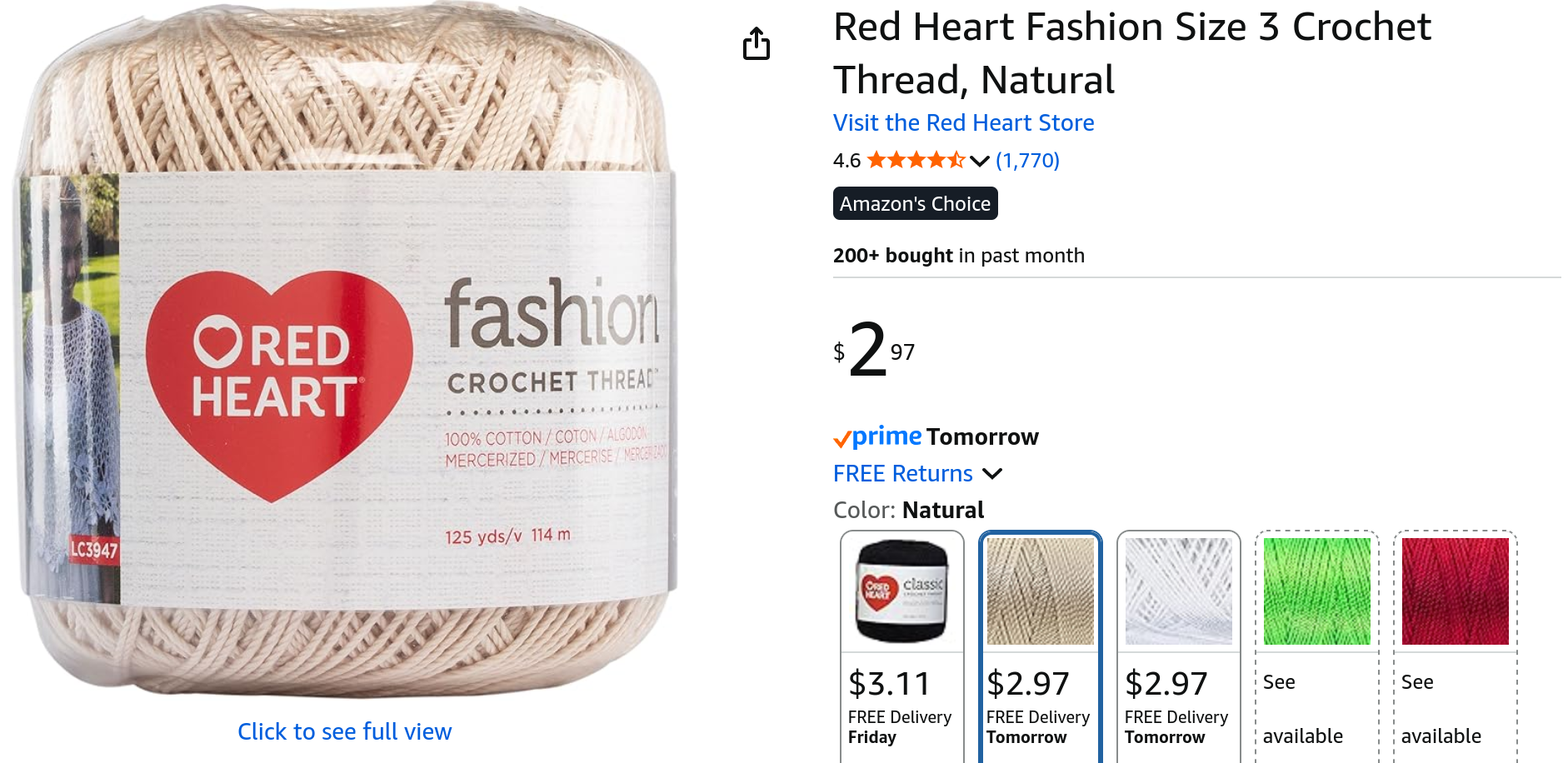

This topic has inspired me to try stitching with larger cotton thread. I often use number 10 cotton yarn for practicing and prototyping, because I like the puffy look and it's available in bright colors. The next size up is "number 3", so I acquired a spool. Here is some number 3 cotton yarn ("natural" color) through the needle. The thread has a lineal weight of 360 mg/m, so it would be TEX 360 if you applied that scale. I used number 10 cotton yarn (black) in the bobbin, which weighs 170mg/m This is on a singer 144W103 with size 180 needle. Here is the number 3 yarn I bought: https://www.amazon.com/dp/B0BRLDP8CB

- Yesterday

-

Here's the link everyone : https://docs.google.com/document/d/1uK_Quj90vuxowtVofD77-GUKnayPjoZyc0AX046l9Uk/edit?usp=sharing If there's any problem, please tell me I'll try to get it fixed ! @JHLeatherwood I posted on r/LeatherClassifieds and on r/Leathercraft.

-

Very interesting. What products have you made with the skins? kgg

-

Funny you should mention that toxo 'cos it's been hovering there in the back of my mind. No hurry though, I'm just happy that I can make useable dies. I've been thinking about a round die for cutting out coasters and I reckon a cheap holesaw should do, grind off the teeth and sharpen the edge. That stainless tubing looks like interesting stuff.

-

A few generations before my time (before 1830 that is) my Naegle ancestors were wine makers. They emigrated to the US from Alberweiler Bavaria, which to my understanding is an area that's bounced around from German rule to Swiss rule and back for centuries. As far back as I've been able to go (1500's?) the Naegle's were there and made wine like the rest of the village and their fathers before them. The old village is still there and they're still making wine. I Google translated the village website a while back, and I think I remember finding a page that listed the families/vineyards in the area and there was at least one with a similar spelling of Naegle that might be a distant cousin, so one day I want to go back and look them up. Now after 1830, not long after arriving in the states my great great grandfather John ran away from home and joined the Church of Jesus Christ of Latter Day Saints (Mormons!) who teach abstinence from alcohol. At that time, they still used wine for the sacrament and grandpa John made wine for that purpose and he sold some too, but the church eventually moved on to just using water for the sacrament and John moved on to other endeavors like growing vegetables, livestock, etc. My family is still part of the LDS church and I don't have any desire to drink wine, but I like learning about the process and feel a bit of kinship to it. A couple years ago I started some vines in my back yard and have gotten into making grape jams every year. I've thought about canning grape juice too, but I still need to learn how to keep it from fermenting but still getting it to store well. Maybe next year... Around here in south Texas the Muscadine varieties do really well. They have a tougher skin so while they're not a good table grape, but they can process down into other things just fine and to my unrefined pallet they taste a bit like a concord. I've also got a couple or hybrid vines going that haven't put out much yet, but should put out red table grapes eventually.

-

Machine & Technics - Sewing wool fabrics with thick linen threads

kgg replied to Ferreol's topic in Leather Sewing Machines

My understanding is the class 45 will take needles having a diameter of 2.5 to 3 mm not 2.5 to 3mm thread, reference ( https://maxandshed.wordpress.com/2020/12/23/une-singer-45k-par-mscr/ ). That makes sense as the class 441 machines take a 7x3 needles having a diameter of about 2.5mm. The max size of thread for those machines is usually around V415 thread which has a diameter of just a touch over .7 mm. A reference chart for the size of thread ( https://www.tolindsewmach.com/thread-chart.html ). I know of no sewing machine capable of sewing a thread with a diameter of 2.5mm. kgg -

Very nice 👍 I love the colour and method you use. I am investigating the Russian method myself but unfortunately I don't have the time to experiment. Can you also show off what you make from the skins? Greetings from Belgium

-

Fool that I am have decided to have a go this year. Know nothing about it except picking up bits through life. Only been here for 3 yrs and last year there was so few bunches that I didn't bother but this year there's about 5 times more. There's still not enough to make it worthwhile so I'll have to supplement with either more grapes from somewhere or some concentrate. A couple peeps on facebook don't want theirs so I'm going tomorrow to see what's left. A whole new learning curve coming up and equipment to buy but two of my daughters will no doubt push me to get it done.

-

Thanks Bob. Took a while though. Ordered the red and black cord cos wasn't sure which one would have the most impact but I think the black is right.

-

Hi Clément I can see that they say that a class 45 will be able to handle 3 mm, I had no idea that they could go that high up in diameter. (Mostly guessing from the numbers since I don't speak French 🙂 ) Do you have any pictures of the yarn / linen thread that you intend to use? I am just curious if you are thinking something that is a bit flexible and pliable, or if it is very hard rolled and compact. Depending on what you want to make, and how many of the same thing you will make, hand sewing is definitely an option. If there are some difficult shapes, machine sewing can be really difficult in my experince. But hand sewing can take a lot of time, and if you are planning on making wool ponchos for sale, I guess machine sewing will be the best for the business. I am at work right now (at a ship), but I'll go home in about a week, and I can try to see how much I can wrangle through my class 7 Singer, just as an experiment. I have some heavy 6 strand linen thread, that I could double or triple to test. I just googled for some macrame yarn, and one type was available in 4 mm, but the most types were 2 mm in thickness. https://rito.dk/jutesnor/32859-infinity-hearts-snor-jutesnor-hvid-2mm-100-meter-5713410015773.html This one is jute, so not linen, but still a nature material. Some of theothers were cotton blended with 20% polyester. I don't think that a heavy duty household machine will have a needle system that will be able to handle a 1.2 mm thread. So you will probably have to find some heavy industrial type sewing machine. Now I am by no means an expert in sewing machines, but please remember that just becasue the machine is an industrial type it might not be designed for large needles. Many of the industrial machines are for sewing fast in regular and heavy fabric like denim, but not with very thick threads. Brgds Jonas

-

Hi Jonas, Many thanks for this complete answer - and very useful advises. Indeed, given this article (in French), they say the "early century machines (including the 45K) should be able to work with a 2,5-3mm yarn". But, that means - yes - finding size 300 needles, and I had not considered that it would cost that much. https://maxandshed.wordpress.com/2020/12/23/une-singer-45k-par-mscr/ In top of that, I have checked with French historical supplier (of linen thread) and their thickest quality is a 1,2mm - so, quite not the 3mm I have been considering at first. The idea of sweing the thread with another thread can work, but I am not sure that the tension of the linen yarn will correct in this case. I think I will consider two options for now : . Hand sewing with a thick yarn (3-4mm). . Working with a 1,2mm thread, and here maybe the job can be done on a regular heavy-duty machine? I will make some trials! Many thanks again for these good words. Clément

-

Yes I’m more comfortable crying and paying for quality once. Yes I went out on a limb with the Techsew but it serves a general purpose of medium duty. Mainly leather bags. Guess I’ll be patient and research a little more before I pull the trigger if I even pull it. I appreciate everyone’s input and suggestions!

-

ben27 joined the community

-

Most machine these days are clones or hybrid clones. The typical brand names are Juki, PFAFF, Dürkopp Adler. Even with the brand names you have to familiarize yourself with what models are made where as not all Juki's are not made in Japan. The Juki DNU-1541S and your Juki Lu-1508 NS are made in Japan while the Juki DU-1181N is made China. I can see between my 1541 and the 1181n there is a build quality difference. The 4800 you have is a hybrid clone of the Juki LS-341, the LS-1341 and the LS-1342. Some people on the forum have bought machines directly from China and seem to be pleased both price and quality wise. However that is not for everyone for many reasons. kgg

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)