All Activity

- Today

-

Here is a great article on what machine or machines you will need depending on what you want to sew. In a nutshell if you are doing: i) Belts and bags a cylinder arm machine similar to the Juki LS-341 or Juki LS-1341 or clones would be a good choice with a flatbed attachment. ii) Holsters you will need a Class 441 similar to a Juki TSC-441 or clone. What is your budget??? kgg

-

Special Holster for Special Friend

chuck123wapati replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Nice indeed!! I like the hidden slots. -

Equipe saddle, repair of worn saddle flap

Mulesaw replied to Mulesaw's topic in Saddle Identification, Restoration & Repair

Hi Tove, Thanks for the nice words 🙂 That sounds like some very plausible causes you mention, I think that the situation in Denmark is pretty similar as in Germany, with very few people being able to invest 6-10.000 Euro on a bespoke saddle. Mys customer is petite, so though she is an adult, she has specialized in training dressage ponies, so I think it was a 16" or 16.5" saddle, And the range of people willing and able to make a huge investment on a special saddle for a pony /pony rider is even smaller than for a full size dressage horse. So it makes sense that it was one of the causes you suggest. One of our good friends had a bespoke saddle made for her horse, maybe 15 years ago. The horse had a bit of a crooked back as far as I remember, not much, but enough that a standard saddle hurt the horse. So she had someone from Kieffer coming up to her and measure her and her horse, and she ended up with a saddle that fit perfectly. I would love to be able to do that kind of work, but I haven't got the knowledge to do a proper fitting on a horse, so I just have to stick with doing repairs (but that is also a nice job) Brgds Jonas -

Well done, Jonas! I can imagine how happy your customers must be — finding a truly well-fitting saddle is still a real challenge. I might have a possible explanation for the one-sided wear you mentioned. From a biomechanical point of view, there are usually two likely causes: 1. Hip imbalance An uneven hip can destabilise the leg and cause the rider to push or load the saddle more on one side. If this comes from a leg-length difference, it can sometimes be compensated for with different stirrup lengths. If it originates in the hip itself, correction usually requires a fully bespoke saddle and close cooperation between the saddler and an orthopaedic specialist. The seat must be shaped according to the imbalance that occurs when the rider sits in the saddle. And getting a bespoke saddler to work with your doctor and really taking the time is almost impossible, at least I know of non who would be willing to do that here in Germany if you are not a very successful sports rider. In those cases, I can only encourage investing in a bespoke saddle. Otherwise, the joy of riding is often replaced by recurring hip pain and cramping — in the worst case leading to painful dismounts and difficulty walking afterwards. This is really, really painful and definitely also makes the horse's life harder. But it's worth the 6.000€ to 10.000€ 2. Knee instability From experience, this is often the more difficult issue. A destabilised knee can sometimes be helped by a bespoke saddle, strength training (though in my experience this is rarely a complete solution), or temporarily fixing the leg position in the saddle. Very often, this also involves a confidence issue after injury. As a trainer, I was always wary of mind-related problems, simply because they take so long to resolve. My own knee hasn’t been fully “fixed” for years after surgery. As a result, I have one very stable leg and one that constantly drifts toward the grid. You can clearly see this reflected in the wear pattern on the inside of my boots — even more than seven years after the operation. Since the surgery I was unable to have a nice and stress-free ride and I loved riding dressage, now I can't even ride a straight line as I confuse the horse with that one leg being a total mess and we tried every trick in the book, besides a bespoke saddle. Best, Tove

-

Welcome to the mad-house, er. . . the forum Patterns; Tandy library has plenty of free patterns, or put a shout on here and I can maybe send you a PDF of a suitable Tandy pattern Tools; tell us what you have and we'll help you spend your money

-

Buttons2 joined the community

-

Haven't worked with any kind of leather since Boy Scouts in the 70s, and those were kits. I am going to get back into Single Action (Cowboy) Shooting, and also hopefully retiring and I'd like to do some leather crafts. I have some leather I bought years ago, and some I just got along with some tools (Chinese). I've got cutting mats from puppet making. I'm not thinking of getting a machine, id like to make some leather belt bags and maybe work up to holsters. I'm very much a plain kind of guy, not thinking of carving, but some stamping for borders. Maybe I'll feel carving is something I'll like later. Just looking for suggestions on tools- like what is really necessary for easy patterns, where to buy leather, if there's a site with some free patterns or templates. Advice for an old newbie! Thanks so much in advance! Kent

-

the "Machinery's Handbook" has enough info on threads to make your head explode.

-

Mglyder joined the community

-

Special Holster for Special Friend

Dwight replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Here you are . . . the rivets you see are holding the card for the thumb break The extra holes are where I anticipated the thumb break would go . . . had to move it . . . sheesh . . . May God bless, Dwight -

Trying out some new leather from Traditions Leathercraft on a larger piece 10 x 6 inch. The leather has a feel that took a little to understand, after it is very nice to work with providing a nice dark burnish. Trying out different aspects bevellling, backgrounding, matting, and cutting. Thus skipped around on the tooling.

- Yesterday

-

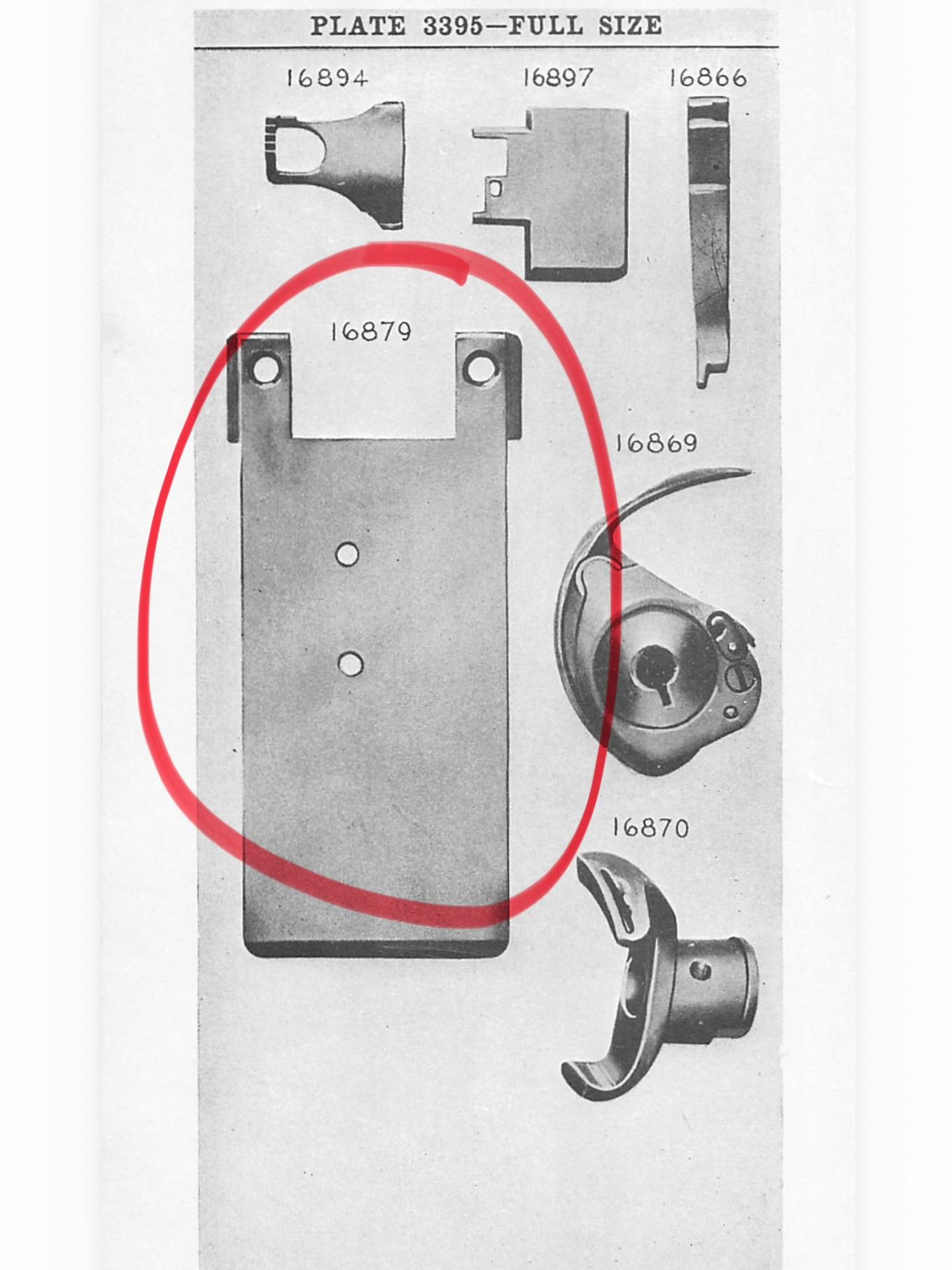

I recently acquired a Singer 17-30. It has a feed dog but no needle plate nor needle/throat plate holder. I found the needle plate I need and ordered it. I can’t seem to find the throat plate holder, Singer part #16879. Does anyone have an idea where I might find one or an equivalent to fill the role? Thanks.

-

What, no 9/64-40? 😉 I skimmed that list of singer screws and wrote down the thread sizes I saw on it. Here they are ordered by size: 1/8-40 1/8-44 3/16-28 3/16-32 3/32-48 3/32-56 9/64-40 11/64-40 13/64-32 15/64-28 1/4-24 9/32-28 5/16-18 3/8-28 7/16-28 1/2-20 9/16-14

-

@catskin @friquant Here is a cheap quick nut and thread gauge that costs under $17 CAD ( $12.50 USD) delivered off Temu and Aliexpress. kgg

-

I used to punch 2 holes and then connect them with a box cutter, could never get them perfect. Still haven't ponied up for an expensive bag punch. A while back i bought a set of cheap chinese cookie cutter dies, all different shapes. There was one oblong one which is the perfect width for the belt buckle. I've had a set of plastic belt end templates for years and use them to center and mark the hole, then place the die on and smack it with my rawhide hammer. The die I use is a touch short so I just cut the first hole and slide it down a bit and hit it again. They turn out perfect. One thing about the buckle slot is that even if you were off a hair it wouldn't be noticeable.

-

I found the easiest way to get a 5/1 speed reducer is from a dead electric lawn mower. My price was $0.00

-

cv66seabear joined the community

-

I have found that screws on Singer 29K and 31K15 machines match metric sizes exactly. I used a METRIC thread gauge and then measured the size with a micrometer. When possible took I the part to try the screw into. Or a nut that matches a screw that size. I haven't found a machine yet that doesn't have 2 screws the same size so I could take one to the automotive or bolt supplier to match. I was set a link by a guy that told me he didn't believe when I said that. BUT the link to the Singer site said MOST Singer screws match other systems SOME do not. So If I were you I would try a good fastener / bolt supplier.

-

WOW! Makes me want a motorcycle.

-

Special Holster for Special Friend

JSage replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Dwight, You do do nice work! May I ask for you to post a photo of the back? -

Equipe saddle, repair of worn saddle flap

Mulesaw replied to Mulesaw's topic in Saddle Identification, Restoration & Repair

Thanks for the very nice words Chuck. It is so frustrating, that I haven't got the answer to why the wear is only on one side. It is really puzzling. I had thought about the "one way" idea too, but it just doesn't make any sense when it is a regular dressage saddle. Equestrian vaulting would fit that category, but that is a completely different type of saddle. And also I am puzzled, why the original owner didn't notice that the saddle got so worn in one side and not in the other side - and in time did something about it. Take care Brgds Jonas -

Internship and maybe a new start

Mulesaw replied to Tove09Tilda's topic in All About Us and Off Topic

@Tove09Tilda Hi Tove Sorry to hear that the internship wasn't a success. I think that @BlackDragon has a pretty good point in that you can follow your passion without it being your career. So I really hope that you'll find a job where there is: Nice colleagues, A friendly and supportive environment, Enough interesting tasks to make you feel occupied. Best regards Jonas -

Tsunkasapa, when I originally saw your thread last night, I found I couldn't respond, as it cut too close to the bone, even though my husband died in 2004. I know what it's like to stand by and watch a loved one fade away from cancer. Time softens the pain, but it never completely leaves. I am so sorry for your loss. And I hope that getting back into leatherwork will help you get your life back and help with the pain. I wish you all the best! Jane

-

Interesting. Finding bolts that fit properly for sewing machines can be a chore at times since a lot has to due with whether the manufacturer is using standard bolts with standard thread pitches or they are using a particular manufacturers specific bolt thread setup like Singer and to lesser extent Juki and Juki clones. Sometimes you can sorta kinda get a Imperial bolt to fit in a metric hole but most times you have to re-thread the hole to get a proper fit. Most machines these days are made using the metric system (International System of Units - SI). The problem of trying to match bolts sizes tends to be a more of a problem in the US as most of the world uses the metric system (International System of Units - SI). Even in Canada and to some extent the US it is not that uncommon to see three systems ( the Imperial, the Metric and the America ) of measurement being used. kgg

-

Of course. For Singer machines that is a viable option, provided you can find the part number. I have a few screws I need to find the part numbers for so I can order them that way. But when I get off the beaten path: Manufacturer went out of business Manufacturer considers my machine obsolete Manufacturer has no dealers from which I can easily and affordable purchase parts Brand name on the machine is not the actual manufacturer Parts list for machine has no photos so you don't know which set screw it's referring to The ease of a midnight transaction on Ebay calls my name then I want to measure the screw and order it by its dimensions. Given that some of these sizes are uncommon outside of Sewing Machine Land, someday I aspire to look up which singer parts are the same thread pitch, major diameter, length, and head style and then order by part number through a singer parts dealer even though the screws are going into some other brand of machine. But that requires a lookup table and the only one I've seen is a good start but lacks screw length and head type: https://www.singersewinginfo.co.uk/screw_threads/ But for today I want to be able to accurately measure screws and at least know what size to ask for at the common internet retailers.

-

acidspit joined the community

-

Very nice been meaning to do one for my ride, absolutely love the little skull piece

-

I would just call Toledo Industrial and tell them what I need a screw for ... 😬

-

For machines where parts are not directly available, how does one measure the diameter of a screw to determine what size it is? To determine thread pitch I've been using this SAE pitch gauge: https://www.amazon.com/dp/B0BGRB96DP and viewing through a jeweler's loupe the pitch gauge snuggled up against the screw for comparison. To determine the major diameter (aka outer diameter, see https://en.wikipedia.org/wiki/Screw_thread#Major_diameter ) I've been measuring the threads with the fat part of the digital caliper jaws. Here's the hard part for me: For the nominal fractional sizes (1/16, 5/64, 3/32, 7/64, ..., 1/2) commonly sold as SAE screws and used on sewing machines, what is the actual major diameter for these screws that calipers or a micrometer would measure? If we were to assume that the nominal size matched exactly its actual major diameter (outer diameter), we could simply generate a table with a little math and multiple by 25.4 if we want millimeters. Here is such a table: NOMINAL | Theoretical | Theoretical 1/16 in | 0.0625 in | 1.587 mm 5/64 in | 0.078125 in | 1.984 mm 3/32 in | 0.09375 in | 2.381 mm 7/64 in | 0.109375 in | 2.778 mm 1/8 in | 0.125 in | 3.175 mm 9/64 in | 0.140625 in | 3.572 mm 5/32 in | 0.15625 in | 3.969 mm 11/64 in | 0.171875 in | 4.366 mm 3/16 in | 0.1875 in | 4.762 mm 13/64 in | 0.203125 in | 5.159 mm 7/32 in | 0.21875 in | 5.556 mm 15/64 in | 0.234375 in | 5.953 mm 1/4 in | 0.25 in | 6.35 mm 17/64 in | 0.265625 in | 6.747 mm 9/32 in | 0.28125 in | 7.144 mm 19/64 in | 0.296875 in | 7.541 mm 5/16 in | 0.3125 in | 7.938 mm 21/64 in | 0.328125 in | 8.334 mm 11/32 in | 0.34375 in | 8.731 mm 23/64 in | 0.359375 in | 9.128 mm 3/8 in | 0.375 in | 9.525 mm 25/64 in | 0.390625 in | 9.922 mm 13/32 in | 0.40625 in | 10.319 mm 27/64 in | 0.421875 in | 10.716 mm 7/16 in | 0.4375 in | 11.112 mm 29/64 in | 0.453125 in | 11.509 mm 15/32 in | 0.46875 in | 11.906 mm 31/64 in | 0.484375 in | 12.303 mm 1/2 in | 0.5 in | 12.7 mm But I don't have enough evidence yet to say whether this is the best course of action, or if there is a better table somewhere based on actual values instead of theoretical. Photos LED loupe, thread pitch guide, and machine screw Matching up threads under magnification Measuring the major diameter with digital caliper