All Activity

- Past hour

-

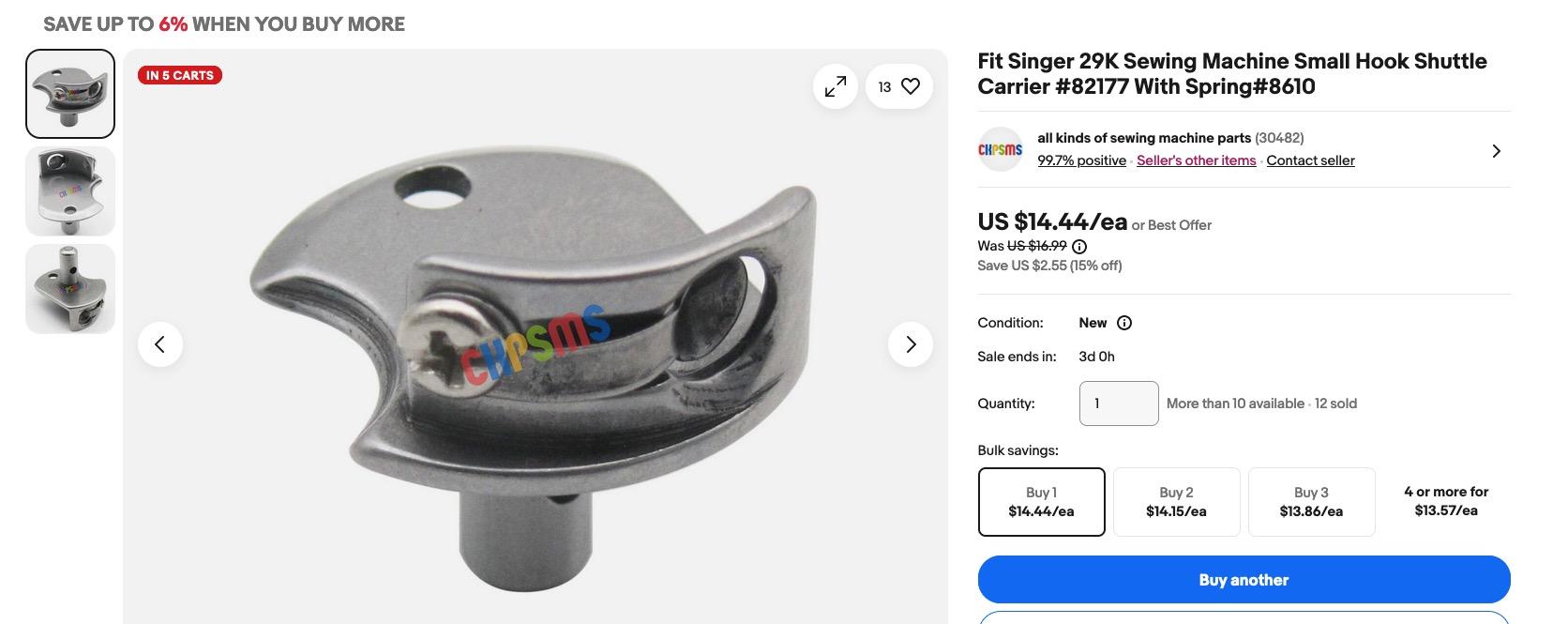

I might have actually found one... It says fits 29k3 and small shuttle carrier..the worn gears I may be able to get around with some shimming...time will tell.

-

I'll post a new thread too, but seeing as thsi is one of two threads here that mention this part...thought I'd post up here as you guys on this conversation will get notifications... I have a 29k3..that i suspect will become a boat anchor...but no harm in asking. any one have a scrap machine and will to sell me this carrier? The shuttle carrier plate is broken, this is probably my fault, but the machine was 'broken' anyway, the drive being so worn and the housing was letting the shuttle carrier move and bump in to the needle. Had to drill out the grub screw. A couple of weeks of heating, soaking / small impact driver and it was not going to move. Think I put weight on the edge of the carrier as I drove it out of the gear So here is my carrier, I do not think silver soldering will save this I see plenty of parts from China..but only the bigger ones for the newer machines, or 11 mm diameter gears where this takes the 3 tooth 16 mm gear. Did any one ever gets parts made for theseolder ones?

- Today

-

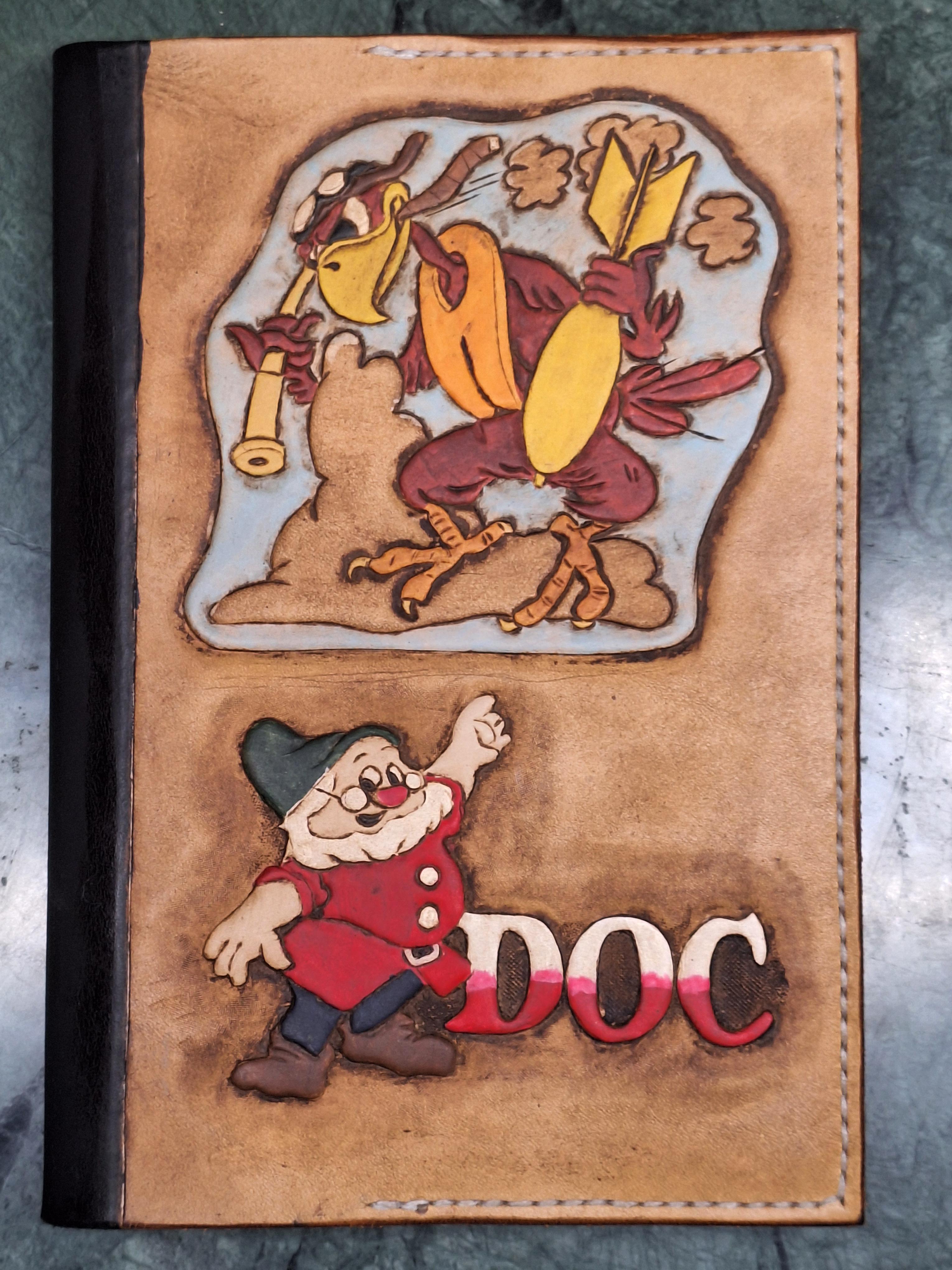

When u design a new holster pattern

Dwight replied to rccolt45's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I have gotten a reputation as the "odd ball" holster maker. Made an appendix carry holster for a double barreled derringer . . . made a double shoulder holster rig that doubles also as a pair of suspenders . . . made a double carry vest for notebooks / pencils / other oddball stuff / could carry a small auto pistol in it . . . made one to carry a long barreled .22 auto with a large scope mounted on top. And that just scratches the surface of my shenanigans. I simply make a decision that "this" holster will carry this weight / in this location / so it needs to be ______thick. I cut a piece that I know will be 1/2 inch to 1 inch too wide and too long along sides . . . get that dude sloppy wet . . . thumb mold to start with . . . then stick it on the vacuum former. Depending on how hard I do or do not want this . . . I may stick it in the hot box for hardening thru heat. Either way it then gets dried. Come back within 48 hours after the above . . . cut out what I need . . . put a back on it . . . glue / trim / sew / sand / and finish. I have more back patterns than I have for the fronts. May God bless, Dwight -

I have some letter templates that look just like that, amongst others. I have done an assortment of lettering, so with practice, that can be achieved. HS

-

I like that 👌, 😆

-

.thumb.jpg.7b83907b17613afe0cdc856f1257806a.jpg)

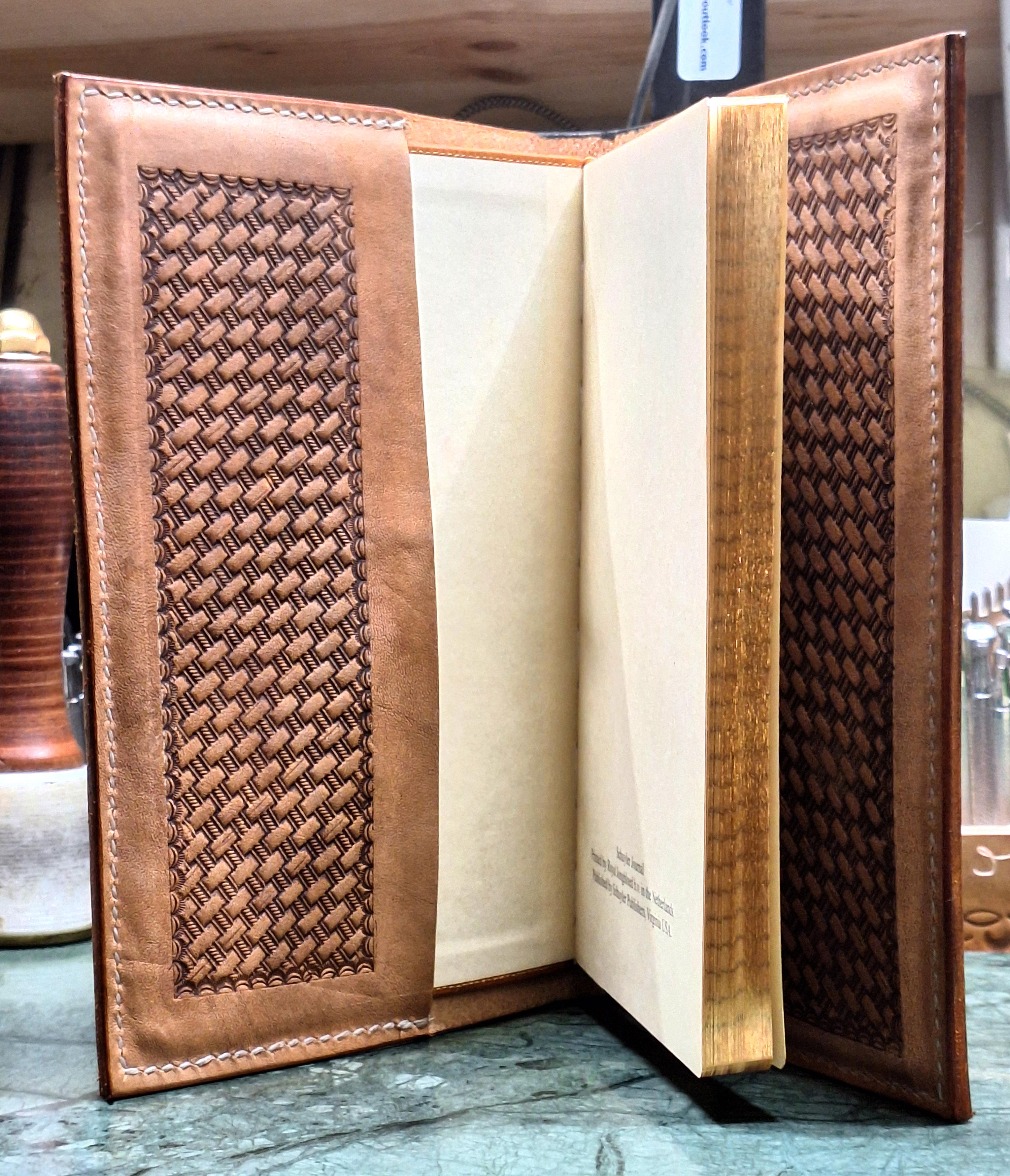

New to the forum and wanted to introduce myself

tsunkasapa replied to Second_Chance_Leather's topic in Member Gallery

I don't do podcasts, but I have a 3 disc CD player and a few hours of the Chieftains or Clapton, Janis and I'm good for the afternoon. Oh, and Jimi!! -

MOST of the 1/4" sets I've seen are on a par with your Tandy set.

-

I have two sizes/wights of the poly mallets and like them fine. I've tried a couple of the round mauls and don't care for them. But that may be because I was a carpenter for 40 years and I'm used to doing things with a 'hammer'. But the poly mallets work fine.

-

When u design a new holster pattern

Samalan replied to rccolt45's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Do all the research, then use really good leather, don't practice, do the job the best you can. Learn from your mistakes and do better. - Yesterday

-

Well when you say "design" a new holster I'll answer from my experience. What I generally do, is make a couple samples without the stitching. Glued, dampened and worked/boned/formed etc. When it dries, I draw on the formed holster the stitch lines and make patterns to match the stitching. Either by working it out directly from the unstitched molded holster, or by cutting it apart on the stitch lines and making stitching templates/patterns from the pieces. After I have my patterns I work up a couple extra holsters and mark stitch lines from these patterns and give it a test as a prototype. If you plan to make multiples or big runs of holsters it's not much of an investment and you can place your stitching very elegantly on the finished products. Leather can stretch in odd ways when you bone it over a mold/gun. Sometimes it's hard to work out where the stitching would actually go, without actually molding it first.

-

When u design a new holster pattern

TonyV replied to rccolt45's topic in Gun Holsters, Rifle Slings and Knife Sheathes

When I built my 1st holster 25 years ago, I simply bought a likely-lookin' piece of leather. I didn't know belly from butt. I've made better holsters from better leather since then, but I still use that old Slim Jim for my '58 Rem NMA clone. I think that old piece I bought was a relatively firm piece of belly, perhaps the upper portion and I've made sheaths and phone cases with it, too. Belly ain't all bad. It's good for learning. -

kemot1975 joined the community

-

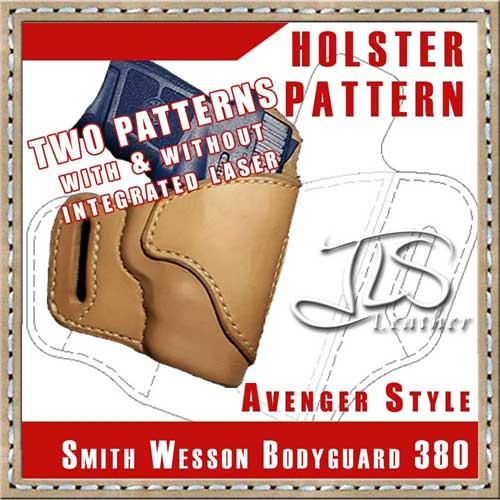

Seems I aint gotno time git round here these days, so I aint passed out too much free stuff of late. So, here's sumthin to play with - don't say I aint ne'ev gih ya nuttin' Follow the structions, it'll fit a S/W bodyguard right nice. Note this is sort of a 'avenger' style holster, right handed, 7/8 oz leather, 6 spi, -- all of this in the pattern if ya check it. BG380_A0.pdf Holster_Inst_avenger.pdf AboutHolsters.pdf

-

As Bruce said, a rubber mallet is probably the worst thing you could use as regards stamping efficiency. There are also many posts on here about people making their own.

-

That's a great book for a leather man, even if you don't make holsters Even better for holster makers. Even if you aren't making THOSE holsters - still good info and experience to have. 👍 That said, Now, if you've already wet formed the leather, then you HAVE your stitch line (right where it's formed). STohlman's books on making leather cases is GREAT for this type of wet forming thing, sewing in the formed line. But SOMEWHERE around here I have some downloadable files, SPECIFICALLY talking about how to lay out holster stitch lines based upon the dimensions of the firearm... Try this? 4 downloads ...

-

When u design a new holster pattern

JLSleather replied to rccolt45's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Use the SAME leather you'll be making the finished holsters with. Different leather behaves differently... and you have already found out that some leather works better than others. Belly leather has some purpose, I suppose (I think the saddle boys and girls use it here and there), but it's not for holsters, belts, or anything requiring firm leather or strength. Once you know the pattern is close and worth a "test" piece, it wouldn't hurt to use a piece of the same leather where there's a cosmetic blemish you wouldnt want to put in the finished goods, but it absolutely should be from GOOD leather, that which you would normally use. If you've read some of my stuff on here, you already know I might often take a holster from teh shoulder leather and make the accompanying belt from the back section of the SAME hide (texture is the same, takes dye the same way, etc...). -

No . . . I put it around me and buckle it . . . or lay it across my file cabinet . . . and never have any problems with it. Someone would have to intentionally do something out of the ordinary to get it to be bent or folded. My friend used to be rather large . . . and his belts would "sag" so to speak. This one does not sag . . . he cinches it up . . . it stays there. May God bless, Dwight

-

I ordered a M57 belt based on this post and found out the 3200 can have either a 56, 57 or 58 inch belt depending on the build date. Ryan @ Neel's Saddlery, where I purchased it, is kind enough to send me a replacement. The belt was lost during a house move so there was not an issue with reliability.

-

This set will be real upgrade... not cheap though. This the only set that I have ever seen that has a "holder" for a line of type. I do not have any personal experience with the seller or this product. https://www.kevinleetools.com/products/updated-new-quality-brass-alphabet-stamp-set Nick

-

Can a worn case/hook prevent adjustment of case opener lever.

friquant replied to beefy's topic in Leather Sewing Machines

Excellent news! -

spring flowers and good food

Darren8306 replied to chuck123wapati's topic in All About Us and Off Topic

I would like to recommend a cnc bridgeport to open those blister packs. You'll maybe need a ruby probe to get the positioning accurate enough, but that should get them open for you. Once you get the codes figured out. You can get small ball heads cheap now, I hear... My thumbs are starting to exhibit the pains and limited movement I have associated with arthritis. My plan is to keep using them, exercising them following the patterns of an aged powerlifter (who is still very mobile and strong) and later, when all that fails, complaining about it to young whippersnappers. Dropped off some more wallets to the gallery, and got some more feedback from the proprietor. Good stuff, and if they start selling better, great stuff. Also stopped in to see a local artist and ask her help. My stamps are lacking a bit of pinache, and I asked her about creating a better 'ptarmigan' stamp. Mine aren't satisfying me, and her style of art makes cartoon characters out of them. I expect it will work better for my purpose, as long as the art part doesn't cost too much. She's a fairly successful artist here, and liked the wallets so much she even said she should sell them. Then she said that she also works with Ruperts Land leather, and kind of backed up on that. I said that I hadn't met the chap from Ruperts Land, but would be happy to share all my tricks and techniques, as I like what I've seen of his work. Maybe I'll finally meet him. Have so far only seen his product on a local facebook page. Sweetheart and I took a beading course for her birthday. Hers is on the left, and we both did well, and have a decent handle on how that works, I think. Good teacher. Lady from Fort Simpson, who came by the skills honestly and long ago. Just let the dog out for her patrol of the yard. Set an alarm, as usual, to remember to call her in, in a few minutes. It gets cold here, and she's a bit of a dainty.