All Activity

- Past hour

-

That little black guide is called a check spring. It's a very important part of the thread path. The "snap' you mention is the sound of the thread snapping behind that teeny little tab, visible through the oval hole next to the screw. If it's not snapping in, try holding the thread that's above the check spring so that it doesn't pull from the spool. At that point in your threading process, you could drop the presser foot. That will clamp the tension discs down and should hold your thread. Based on the angle of the thread coming off the check spring, it looks like it's behind the tab. I think.

-

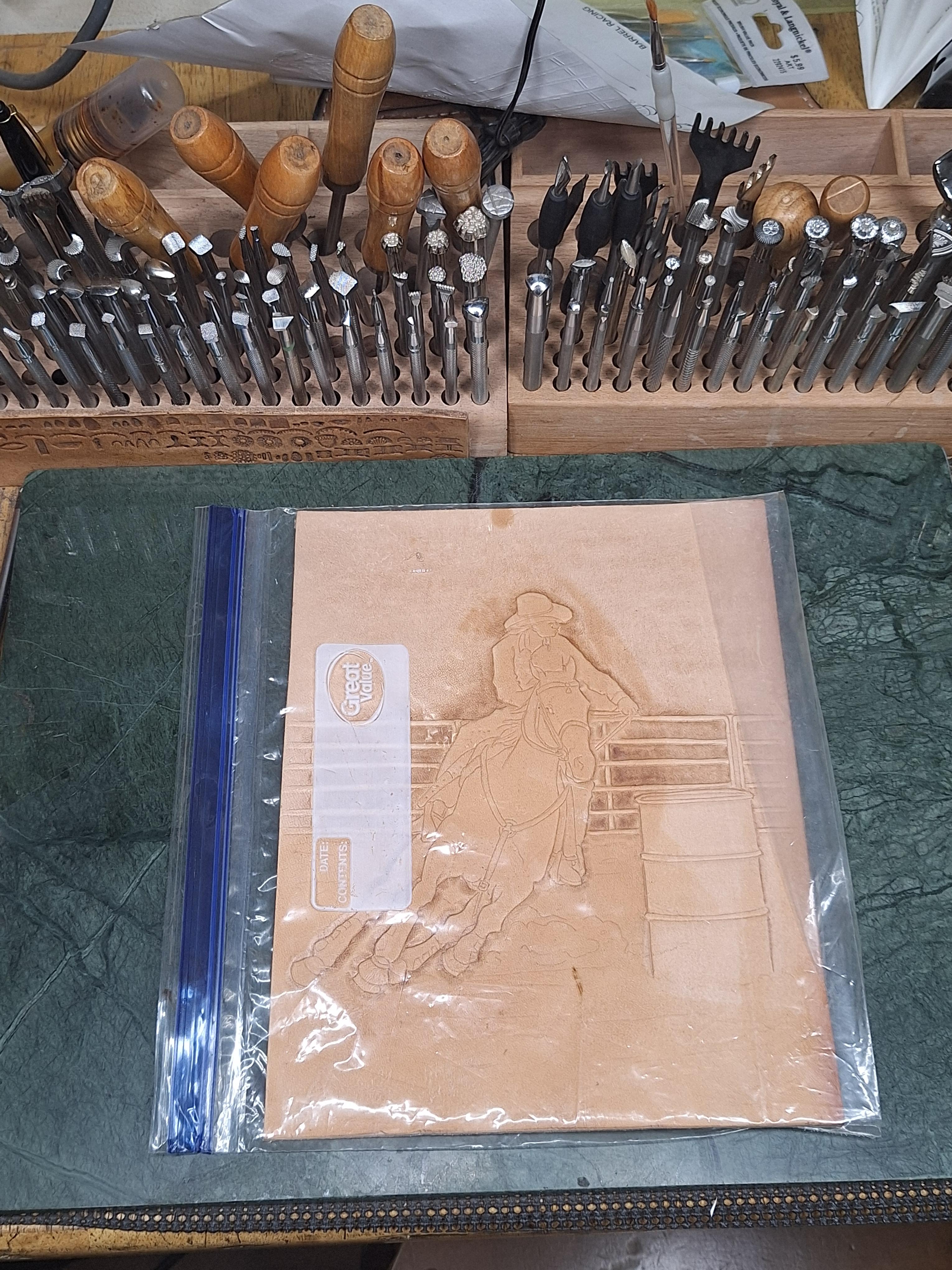

What's on the bench today? Barrel Racing, thought it would be fun to do a womans Western sport carving.

-

Is there a sewing machine for me?

Wizcrafts replied to D.jsherwood's topic in Leather Sewing Machines

You'll need a walking foot machine for this job. It could be a portable walking foot machine made by Sailrite. Or, it could be an industrial machine head mounted on a 20x48 inch table with a clutch or servo motor under the table. -

More experienced voices will no doubt chime in here but you should be able to get into a used machine with that budget. A tight budget, for sure and your may end up with a fixer upper, but doable. I'm thinking something in the range of a Consew 206RB-x (x being a number up to 5), or one of it's many equivalents. Start fishing what you find past the experts here and you'll probably get great advice. I'd only suggest holding out for something with reverse. You don't need it and not having it will save you money. But you'll experience a feeling of lack every time you use an older method to lock your stitches.

- Today

-

Hello all. I just joined here to ask you all gor advice on what machine to get. I dont have much, I really can only go up to about $650 on the machine itself, and I need it to redo a boat interior, so, vinyl. It seems as though each time I find one I think would work, I see one you all or folks elsewhere saying not to get it.

-

I was trying to figure out what might have caused the issue initially and it became clear very quickly when rethreading! So the little black guide photographed doesnt click as I am led to believe it should? So the thread gets wrapped around the disc after a couple of revolutions and the thread tension is far too high. Ive asked a lot from you already but do you have any further advice regarding this matter? Thank you all again, Merrick Sorry, photo attached here

-

first pancake holster

dikman replied to Thadrick's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Very nice stitch lines! -

Awesome! 💃 Make sure the handwheel turns freely (easiest to check with motor drive belt disconnected), and that it forms stitches. If all checks out you can reconnect the drive belt and go back to stitching under power. The safety clutch may disengage again if too much load is placed on the hook driving shaft. Two things that will make it go much better for you: Start each seam with the take up lever at its highest position Hold the top thread for the first couple of stitches

-

what are you needing? glenn

-

I tie the knot between the layers then cut the threads as close to the knot as I can get with my utility knife. I don't use the knife to slice the thread in a cutting motion, but pull the thread against the thread so that they make the cutting motion. This helps avoid cutting the leather. If there is any little tag of thread still sticking out, just tuck it in, then hammer the seam.

-

Yeah, that's the vid I was thinking of. Or, just upsize the purse-size pattern to your liking.

-

Using neatsfoot oil

TonyV replied to Mungo's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

Even on very dry leather it is easy to use too much oil. I usually apply just a light coat of NFO to the grain side and give it time to soak in. If it's still too dry, a 2nd light coat may be in ordre. Time to absorb is almost as important as quantity. Remember, you can add more oil if you need to, but it's pretty tough to remove it, and oil-soaked leather is just nasty. That said, I had a cetain piece of veg that was dryer than a math lecture. I brushed a bit of NFO on the flesh side and it definitely helped. -

Well Ill be damned, less than 24 hours and you have helped me troubleshooting an issue ive had for over a year. The drive shaft is now turning. Ill keep you updated on any issues that may follow... do I use it manually to ensure that all blockages are removed for the time being?

-

Spot on, I'll go and try to reset it now. Thank you

-

I’m a complete beginner who’s just about to start the journey into leathercraft. I have a few questions about tools and my first project. Please excuse any misuse of terminology—I’m still learning and doing my best to explain what I mean. Tools From what I’ve learned so far, to start I’ll need the following: a burnisher, edge beveler, wing divider, metal ruler, self-healing mat, stitching chisels, rubber mallet, stitching needles, scratch awl, and craft knife. Is this a good basic setup or am I missing something important? Project My first project will be a motorcycle seat cover made from sheepskin hide. I know this might be too ambitious for a beginner, but it’s something I actually need and it motivates me to learn properly. That’s why I’m carefully planning each step to avoid mistakes. Here’s how I imagine the process: Cut the hide to fit the seat area I need. On the back side, glue a nylon strap (in 2-3 places) with a stretch (elastic) strap sewn in the middle. The goal is to have enough slack to go under the seat. Basically, I want to create small “waves” in the nylon strap and sew it onto a straight stretch strap—so the nylon will limit how much the elastic can stretch, just enough to go over the seat. The nylon strap will go between the sheepskin and the outer layer (next step). Or will just use a side release buckle. Here I’ve hit a problem. The sheepskin is quite stretchy, thin, and soft. I’m worried it might tear. I’d like to glue something to the back that repels water (to protect the skin from moisture) but still allows it to breathe. A bit of padding would be fine too. Do you have recommendations for what material and glue would work best? I also plan to leave a few centimetres of material as a “flap” around the edge of the bottom layer from step 3 (except at the front and back). How should I treat or finish the underside of the skin? I’ve read that Tokonole can be used to burnish edges—can it also be used to protect the bottom surface from the elements? And finally, what should I use to clean and maintain the sheepskin over time? Any other advice or suggestions are warmly welcomed! Photos as examples, not exactly how I see it, but somewhat similar.

-

You may need to engage the safety clutch manually, with a screwdriver. Here is a video that shows how the safety clutch mechanism works, and how to disengage/engage using a screwdriver.

-

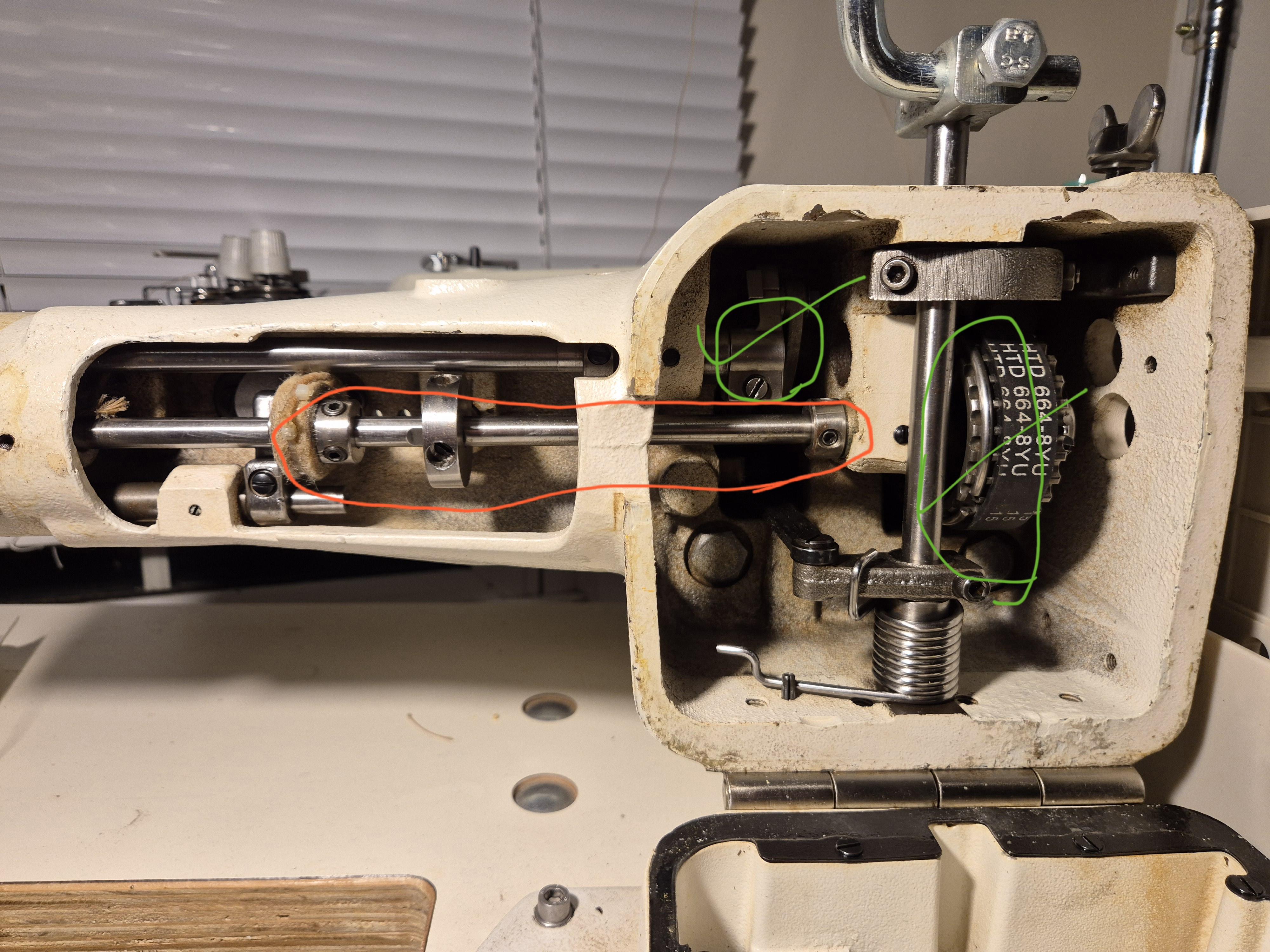

Hi Wizcrafts, I remember reading a lot of your posts when choosing this machine in the first place, you were very informative. Please find attached a photo (hopefully) and see if this would make sense regarding those diagnoses. The area circled in red (I believe is the hook drive shaft) is not turning with the areas circled in green. Thank you very much, Merrick

-

Either the safety clutch has tripped due to a thread jam (most likely), or the driving gears have loosened on the drive shafts.

-

Ah okay, ill try to find a suitable file format. Thank you for letting me know. Basically, the handwheeel turns but the drive shaft for the hook is not turning with the rest of the mechanism when viewed from the underside of the machine. Everything else seems in order! Cheers, Merrick

-

Nice job on that, Dwight, especially the basket weave and color.

-

Can't see the video's with a message of unspported format and MIME type found. kgg

-

Using neatsfoot oil

kgg replied to Mungo's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

Depends. I use JoJoba rather then neatsfoot oil. What I do is oil the flesh side first using an airbrush to get constancy over the area, let sit, maybe re-oil, then airbrush dye on, let sit and airbrush oil on again. If I'm dying the other side I will follow the same process. I found the grain side will suck up more oil or dye much faster and suck then the flesh side. kgg -

Internship and maybe a new start

BlackDragon replied to Tove09Tilda's topic in All About Us and Off Topic

Not sure why I didn't see this thread until today. I've been in the work force since about the age of 15, I started out in a company that made sails for all types of sail boats. I sewed banner flags and bags for the sails, then slowly worked up to laying out the sails on hardwood floors to later on sewing them together. It was great and it taught me a lot and still carry much of that experience to this day. I understand completely the frustration about getting a degree and not having that degree produce a job. I got a degree in advertising design in Florida and after graduation I applied to a lot of companies to try to find work, I even tried Disney & Warner Brothers (Bugs Bunny). Most of those companies were very small roles and they all had similar statements "You don't have enough experience". Which didn't make much sense to me because they were jobs for starting out. I couple companies actually stole some of my ideas during the interview process. I did a few small odd jobs here and there as a freelance artist but not enough to pay for fuel, lol. I went to work in various manufacturing companies over the years and most of those companies are not for people that want to express their artistic talents. This would include a company that manufactures saddlery. They have a set way to make a saddle and unless you get into a company that actually wants to change the way it used to be done you're not going to have much say in how to change it. When I worked in manufacturing I've seen the dead look in peoples eyes as they did the same repetitive jobs over and over, every day, for years. I've even had that look myself. I learned to balance my time outside of work to counter that feeling. I was a bit of an adrenaline junky, jumping out of planes, became a dive master, cave diver, deep diver, and did beta testing for various companies. If you can't find something you love to do as your career it's not the end of the world. Do your passion while you're in the job you need to survive. You can still follow your passion without it being your career, just balance your life. Even if you're following your passion as a career you'll have to do the things you hate in order to do that career. Like taxes! LOL -

Thank you so much for your guidance.. I have tried to reengage the safety clutch but nothing is happening to the button as I push the hand wheel back, I can feel a very small amount of feedback but nothing past that, it certainly isn't dropping down as I believe it should? This is my first industrial machine (actually my first machine altogether), it might take me a bit of time to troubleshoot, please bear with me! Thank you very much again for your help so far. 20260120_182522.mp4 20260120_182905.mp4

-

D.jsherwood joined the community