-

Posts

7,378 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by JLSleather

-

Ridiculous, isn't it? But then, I had a specific purpose, aimed at showing people here that you CAN get these to fit that machine. And there's no modification needed -- just get two parts. And show where to get those parts. Hey, I'm the LAST guy to tell people watch a video. Usually. I pacify myself with knowing that it's not 'fluff' and noise -- actually DOES something FOR leather workers. No hour long, 2 or 3 part "series". No loud, fast "hype" to pump anybody up. No sales pitch. No offer to show how to do something, then not actually show it. Answers a question I had, and shares that answer with others. No need to sign in. No subscription necessary. Don't 'like' tweet, twit, or twizzle. But I agree. Ridiculous.

-

https://www.youtube.com/watch?v=vWd4FlRHv-Q

-

Yes, "whelp" was an attempt at hillbilly humor, a personal rendition of a "redneck joke", farce. Officially, it's a welt (in this case, single layer of heavy(ish) leather stitched between the back 'n' front to open the form without making it wider side to side.

-

Perhaps he's very skilled at measuring 12".

-

Yep, and W/C got good stuff, too... not just marking up somebody else's low end stuff.

-

Yeah, I'm not sure what was life-altering about that ball myself Still, I can tell you can get one of these drop-down thingies for CONSIDERABLY less than a side o' cow. Uwe (above) has them in his ebay store for about 1/3 of a side (ish). The 867 guide and 205 bracket work as is.... no modification necessary. Screw in 4 bolts and off ya go...

-

Front, back, whelp.

-

i haven't sewn anything in the 1/2" or up range for a long time. That's 4 layers of 8/9, and I'm generally about 'capped off' at 3 layers (which I DO sew all the time). I think the CB3200 is good money -- prolly what I would get. I DID have one of the 206-RB5 machines, and if that girl gets tired of it i'd buy it back. Maybe she'll use up the $100 worth of thread I gave her and then not need the machine any more ?? But the Boss.... I dont see the point. While I understand it will throw a little heavier thread than the 3200, I have NEVER needed 415 thread (or whatever that size is), and if you add about $300 to the price of the boss you could be running under power

-

Now, here's a bit of the issue I have with these things. I know it's not a precision instrument, but it could have been done better than this ...

-

Oh, gotcha. Either is tall enough for most of what I sew, so that's not an issue for me. Can see your point, tho.

-

Oh, boy.. this does bring back a point I've tried to make more than once. Finished goods are often priced by some "formula" involving cost of materials. So, if someone buys "B" or "C" leather at $12/foot, is there finished item then worth 20% MORE than the person who bought GOOD leather at $10/foot? OR, (and this gets MY vote) should leather goods (and about anything else) be 'judged' based on the quality of what it actually is made of, and the quality of the work in it? Compare, compare, compare ...

-

If she does the grocery, she'll understand. Tell her you aren't going to drink a gallon of milk today, so you've decided to just buy one or two of those little cartons from teh school lunch menu, which cost as much for 4 as that whole gallon she's "wasting' money on

-

Maybe they get their "own" sewing machine first! That one is from one or more factories in Asia. But now that i've seen the mark-up on these little edge guides, maybe I'll "come out with my own" too!

-

Splinter’s Sheridan Style Beginning

JLSleather replied to splinters's topic in Floral and Sheridan Carving

Glad I was able to help. Honestly, tooling is quite simple. You DO need to start with good quality leather (or it won't matter much if you know how or not). But with a good chunk of leather, the only ones who can't tool are those who are telling themselves they can't! Gimme a good piece of leather, and I can teach a monkey to tool it -- long as he aint too drunk. But if you want to see REAL talent, check over there in the braiding section!! -

YES - that's my point. I got emails about prices going up, but emails were not FROM H.O. A number of suppliers "around here" raising prices (again!). Sometimes they bump up the price. Sometimes they downgrade the quality or the grade of the leather, but charge the same, so they get a "price increase" without looking like it to the untrained customer. SO to be clear .... Hermann Oak has NOT had a price increase. The reason I add "For Your Information" is because it is just that - information. I'm just letting people know where and how to get the best leather you can get - delivered to your door - for about $185 each (no belly leather). H.O. "B" grade backs (no belly) running $9 / foot. Add the shipping, and it's at $10/foot (19 feet for $185). And it really IS "B" grade. So, WHY would anyone want to pay $12/ft, when you can get BETTER leather for $10/foot?#@#@!! This is a 25% MARKUP on the LITTLE GUY price (and don't kid yourself, they're brokering a MUCH better deal). Even with the "free shipping" some yelp about, you're still paying $2 per foot MORE for leather that isn't as good. I have certainly received sides from "suppliers" which were NOT "B" hides, though that's what they were calling it. Sometimes, I find a good deal, or a good idea, and pass it on to other folks around here. But it's just information. If for ANY reason people prefer to pay more money to buy lower quality, not up to me

-

If I didn't have a machine, and was looking to stitch stuff like that great lookin holster you posted, I'd call Bob and ask if he got a Cowboy 3200 with no shipping label on it as yet. It's "under $2k", but sews with a pretty versatile range of thread / needle combinations, will handle a couple layers of heavy leather easy enough. And it's slow enough to be a "beginner" model (no fingers stuck to the table).

-

That lid is held on with glue. Got a hot glue gun? Turn the pot over, BOP the edge with a rawhide mallet (or similar) and the entire lid will come off. Then just PEEL the dried glue out.. maybe a use a dowel or such. It will come out like set-up putty. I say use a dowel, because something metal (like a butter knife will mar the teflon, and it aint so 'non-stick' next time Once ya gotter cleared, hot glue the top back on, and go on about the leather .... Oh, yeah -- once you got the top back on.. a little glue thinner in the pot and the brush set in place, and the brush will fix itself pretty quick.

-

Officer's model python

JLSleather replied to supercub's topic in Gun Holsters, Rifle Slings and Knife Sheathes

SHARP! That the 3.5"? I got confused for a minute, reading "officers" and "python", since Colt makes BOTH. I got a piece o' snake left myself. Was gonna do it surrounded in black HO, but now I see how good it looks in that tan color... don't know why I didn't do that before! -

TIP: If you use a spray adhesive, you can easily stick the printed pattern to poster board, or whatever you use for patterns you want to re-use. Spray both surfaces, wait a few seconds, stick SMOOTHLY, and THEN cut out the pattern -- being sure to cut the outline OFF. This way, you can use the sheet with the "hole" in it to mark you leather, and see the leather you're about to use. The cut out can still be used for glue / dye blocking, When you cut it out, keep in mind the line needs to GO. This way, the width of your pen / marker / scriber won't 'shrink' the pattern.

-

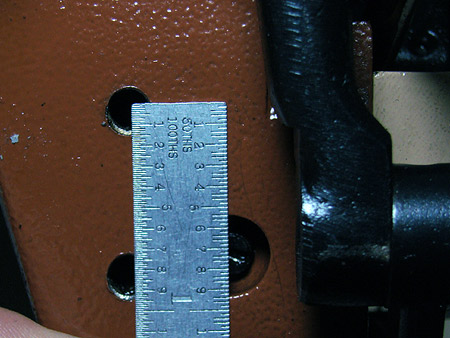

Sue weeeeeet I did email that web site.. see what happens there. But I WOULD be willing to test this out -- so I certainly appreciate your offer. We all know how that "sucks" ordering multiple 'versions' to get the one that fits what we're doing! So, the one that comes with the Cowboy machines is a curved mounting plate? Here's the back of the cobra (4). Not a metric scale, but the caliper says 20mm center distance, so .. .800-ish on this scale.

-

Poll on Revolver Safety Strap

JLSleather replied to JLSleather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Well, yeah .. they can be made to get out of the way Two layers helps, and then DON'T form it around. SO simple, can't believe I didn't automatically see it in the first place!- 7 replies

-

- revolver holster

- safety strap

-

(and 1 more)

Tagged with:

-

That looks like it'd prolly work. Thing is, though, WHICH of the guides better suited? That site doesn't list ANY sizes / measurements. Ideally it would be large enough to reach without adding a lot of 'stuff' right in the work area. I should have measured from the holes down to the cylinder, but not much good to know what that is if that still doesn't tell you which guide to use !

-

I think that's the same company I tried to contact today. Figured I'd check on what they got (looked like the 767 and the 867 would probably work?). Long as there isn't a minimum order of like 1000 units, I might just pick up a few so they're around when other folks take the notion. But now that I'm done for the day, I think I'll go measure them there holes. Drilling a hole is fine. Long as we don't have to drill in one side of an existing hole ... OKAY< then.. the official version... two holes (up and down like in the pic Al put up there). Likely 6mm (hole measures about 4.4 mm) and spaced pretty close to 20 mm centers.

-

Yikes. Another video. Well, at least this one had SOME value... saved me spending $100+ on a cheap litle bracket. The roller guide would be the only thing on that costing more than $2. .. roller bushing maybe $10?