-

Posts

7,386 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by JLSleather

-

Glock carry set

JLSleather replied to Josh Ashman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

-

Large Leather tooled Bald Eagle

JLSleather replied to hashtagartz's topic in Leatherwork Conversation

Never an eagle that large. But 'back when" I did do a few landscapes and a steamboat and a Santa Fe locomotive. 18"x 12" was popular for a bit - not sure if it's because of THEM or because of ME. -

Yeah - "buscadero" incorporates a slot for the insertion of the holster. Acts to drop the holster (and thus the pistol) lower, which may allow for an easier draw. That is the reason I prefer the angled wear, curved belt - long legs, short torso makes lower = better for me. But I don't believe that one "stays up" better than the other. My straight cut belt in my jeans holds up itself AND the pants. Since I no longer own this type of gun, not a huge deal for me other than the way I explain it to others. Incidentally, been a while since I made one of these. Seen a long line of folks these days seeing $150 stuff on Amazon and wanting me to make it for that (uh, thank you no). Josh covered the issue of curved / straight (nice belt, BTW). I've always cut them curved, but that's more because of the way I learned than actual necessity. If that's a "secondary" issue, then let me hit the tertiary ... "No butt" is almost always the direct result of sedentary life style. Really it's just another name for muscle loss - "atrophy" for the fancy smancy folk (and at the risk of having the thread moved to like a 'fitness' section er sumthin, it's the same thing responsible for the swelling of the belly region). SImply put, less activity results in muscle loss, and muscle loss results in less calories burned. End result: flat butt, not so flat belly. Dad was one exception - that guy had NO butt his entire life.

-

S&W X Frame Field Holster

JLSleather replied to chiefjason's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Does that come with WHEELS? Or maybe a buddy to help carry it! -

Chest rig for a Glock 19

JLSleather replied to Hags's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Clean lines, tight stitching, nice color .... I LIKE IT. I'd want a bit less vertical for my wrists, but this is clean work -

I Tried To Make A Pancake

JLSleather replied to AzShooter's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thenit sounds like ya nailed it -

Like everything else, some veg goat is quite nice and some isn't. Attaching a pic - this one was done a good while back, with a 3 oz veg goat lining. Oh, and your holster weight sounded pretty heavy to me too, but ... let a guy build his own way, I say

-

Stohlmans book on How To Make Holsters has patterns for 1911 pistol AND a shoulder harness - should be very easy to adapt both to something that suits your dad. I don't really make those rigs (for years now) but I would recommend SOME type of retaining strap. Bending over on the farm (or over the edge of the boat to lip that bass) can go badly in a hurry (yeah, I know for a fact).

-

-

rainy day holster

JLSleather replied to CindyCLewis's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I use glue, but alternately I have seen people sew (relatively close to edges) and then use an edge coating. Course, the separation will still be there, the coating is just that.. a covering. -

Leather Dies - Milwaukee vs Texas - Overthinking?

JLSleather replied to Gulrok's topic in Leatherwork Conversation

At those prices for a bifold, I have to assume you are needing "gang" dies... stamping multiples with each hit. That being the case, I don't think $70 would be an issue that affects choice at all. Nobody wants to "throw away" $70, but far more important in this case would be the reliability and ease of use. The more pieces the die cuts, the faster the cost difference is made irrelevant. More important issue would be how the die handles, cuts, stores. Having said that, I can say I have never used Milwaukee. I do have a number of dies from both Tx Custom and Int'l Dies - and all cut well (but, these are single part dies, if that's a consideration). -

Okay, One. More. Time. Tandy does stock some stuff I wouldnt' use, ever. But I HAVE purchased some perfectly usable tooling leather at Tandy stores in Iowa and Minnesota. Their tooling double shoulders have gone into quite a few of my projects.

-

Then it's likely the tanning process used on the leather. I wouldn't always take what somebody said about their results as accurate, but you seem to have a very good grasp of what you have going on and what to do about it, particularly for a "new guy". Sometimes, it really is the leather. I tool both Hermann Oak and Wickett-Craig leathers, and they are NOT the same. Both are good, but NOT the same. Did I mention they aren't the same? This guy's leather is FAR too wet. Ridiculously wet. Maybe it's ready to tool after dark ...

-

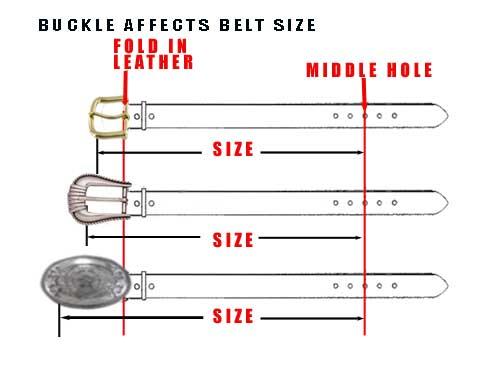

Worth noting, the THICKNESS of the belt matters too. The thicker the belt, the longer it needs to be to fit correctly. A 39" measurement on a 7/8 oz belt will NOT fit the same as a 39" measurement on a DOUBLE LAYER 7/8 oz belt (the double layer belt will be short by nearly 1").

-

Well, I can't adjust your waist for you If you gain 1", should be able to "skootch" your buckle over half an inch and be fine on the name placement. If you gain or lose TWO inches, maybe fix that issue. IF you gain or lose more than that, maybe invest in a new belt.

-

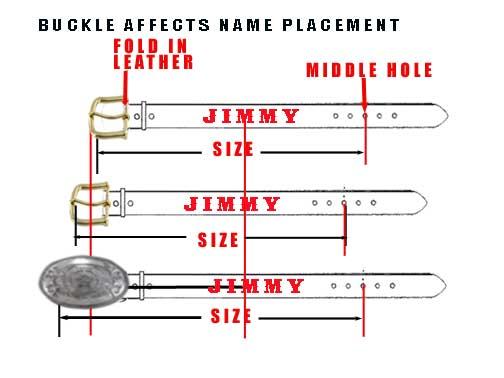

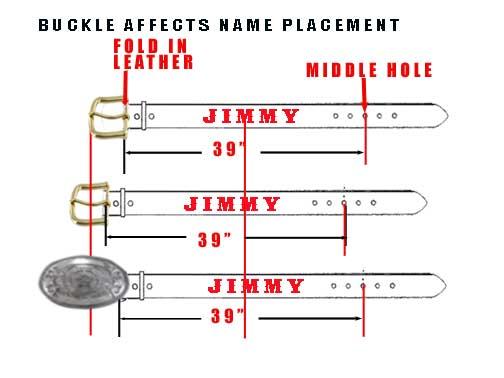

Uh, yeah - I usually don't comment on videos, cuz ... I don't generally care for marketing thinly disguised as "instruction" or "help". But since you admit you're addressing "other questions" I suppose that's a start So to add, ... I would never "center" a belt by fold 'n' eyeball, but each his own. The real issue here is the measurement WILL work (the belt will fit) since you're measuring the existing belt and the new belt the same way (hole to fold), but the name is going to be centered ONLY IF you're using the same buckle or one close to the same LENGTH. And, My daughter says that girl's shirt is "cute". To illustrate the issue with buckles, consider .... This pic shows 3 belts - identical in width and length. So basically, 3 copies of the same belt. In the video, this measurement from fold to middle hole was 39". By changing the buckle, you change the "size" of the belt, though the leather you cut is the same. The buckle length is part of the "size" of the belt. We use this quite a bit on belts for youngsters, who tend to grow quickly. Make them with a short buckle, and in 6 mos or a year he can continue to wear that same belt just by swapping out the buckle for a longer one. Conversely, this pic shows that with the SAME belt, placement of the name CHANGES depending on the buckle used and how it is worn. Assume that the long red line to the left (buckle end) is the zipper line (center) of your pants, and that the other long red line is the middle of the back. Your front is your front and your back is your back, these do not change even if you're aren't wearing a belt at all. Now consider that these 3 belts are again identical - they all measure 39" from fold to middle hole, and the name is half way between the fold and the middle hole on ALL belts. If little Jimmy wears his belt so that his buckle lines up with the zipper (top), then this name IS centered on his back. BUT If Jimmy wears that SAME belt so that the center of the buckle is the center of his body (middle) then his name IS NOT centered on his back. AND ALSO If Jimmy wears a "trophy" buckle, and that buckle is worn centered on the front (bottom) then again his name IS NOT centered on his back. Maybe this is a bit more clear? All belts are the SAME, but the buckle affects both the SIZE of the belt and the NAME position. From the video, "center" would be 19.5" from the fold (and 19.5" from middle hole) , which is what is shown here. Clearly, if you wear your belt with the buckle centered in the front, then the name would be OFF CENTER by half the buckle length.

-

First custom dog collar

JLSleather replied to benlilly1's topic in Collars, Cuffs, Leashes and Leads

Looks nice. As I always ask pet collar makers, please consider using conway buckles. This type of "heel bar" buckle causes the owner to go PAST where the collar fits to buckle it. I dont mind suckin' my belly in a bit to hook my belt, but I dont like to ask a dog to suck in his neck. The rest of the construction is exactly the same. -

I was gonna suggest what most suggest around here -- look for a video Which, of course, kinda negates the point of THIS site, really. But I see somebody ALREADY did that - TWICE

-

I have never seen a "stamp" for grade on the back of an HO side. Generally it's their stamp, plus somebody WROTE the grade in a single letter with a marker (often green, though I've seen other colors). Maybe this is different outside the US? I ordered leather from Weaver ONCE, and will not do it again. Been probably 5 years or better. The hides I got were entirely unacceptable. Did they know? Either they DONT KNOW what good leather looks like, or they DO KNOW and were hoping that I DIDN"T KNOW. Either way, they burned that bridge. I sold the leather for about 30¢ on the dollar to a guy who makes knife sheaths and so was able to cut small clean parts between the marks COVERING those sides. Supposed to be HO A/B grade, but .... YIKES. Fortunately, I had only ordered a couple of sides to "test the water" to see if I wanted to buy leather at Weaver. Now I know.

-

Cold Dead Hands Holster

JLSleather replied to hashtagartz's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Grinch green? SHOOT... I bought KELLY green, haven't tested it yet. 'Preciate the response! -

Cold Dead Hands Holster

JLSleather replied to hashtagartz's topic in Gun Holsters, Rifle Slings and Knife Sheathes

What did you use for the green? That's about the shade I need for upcoming project