-

Posts

7,386 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by JLSleather

-

-

From the album: Seriously ...

Old Stohlman design for the SW 'L' -

From the album: Seriously ...

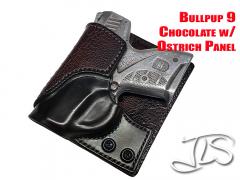

Bullpup pocket holster accented with this lizard hide with a bit of a digital camo look - definitely like to find more of this skin ...© 2020 JLS Leather

-

- pocket holster

- lizard

-

(and 1 more)

Tagged with:

-

From the album: Seriously ...

This is the SAME holster, just to show how different it can look depending on the lighting, the backdrop, the angle....© 2020 JLS Leather

-

- photograpy

- p238

-

(and 1 more)

Tagged with:

-

Doesn't look like it... some of those bunkhouse rolls are pretty big - these bars look too close together

-

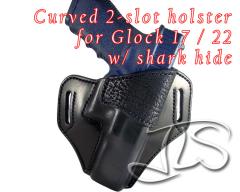

Ooops... busy thinking about the hardener that guy was on about and forgot the paddle question. The "leather" paddle holsters I've seen and actually cared for had KYDEX cores sewn between layers of leather. Idea is to keep the contour flat as possible - I mean the curve at the top of the paddle piece - so that it doesn't kick the gun grip OUT.

-

I'm old enough I remember that smell - without doing a chemical analysis, I'm willing to say that resolene and floor wax pretty much the same thing. And while I've never 'home made' antique, I did once blend some Tan-Kote with some fiebings dye (which isn't "supposed to" work - an acrylic and an alcohol - before they called it pro dye if that matters) which worked out nice enough people who saw it asked me to mix it again. Course, I hadn't even considered that so I had no "formula" for getting that same shade again but now they have jars of STAIN which is virtually the same thing

-

SAME with the bunkhouse embosser. So I just don't make ONE strap.. while I have it centered for that width of belt and that roller wheel, I make a bit more than I need before changing it out, so if somebody orders ONE (which has happened) I have one already ready (but don't store dozens of each design) Were we doing "production" work, wouldn't be a considereation, we'd just make BATCHES of each design while its set up

-

Anybody ever tried that "leather hardener"? Goofy little fella, but that don't mean the product don't work ...

-

SHOOOT... i was headin' fer maybe like a tuck-tite... but i like your idea better (SHUCKS.. I HATE havin' ta credit somebody else ) Have to check dimensions, see if there's one that's solid but still fits on this little gun.

-

I didn't think those holsters LOOKED too bad (cosmetically), but now I'm realizin' theys got a lotta twists n turns that just weren't necessary at all. Oh, well --- give a fella what he wants, eh?

-

No trouble -- I'd prefer a guy ask just like you did than assume he knew what I meant, when he DIDN"T know what I meant

-

Second that. Also, perhaps it isn't absolutely required to make sure every person you speak with learn every bit of what went on yesterday. We used to hire some of the boys coming out of "the ranch", and some of them just basically good boys who did something stupid and now want to get on with a normal life. I promise it would not occur to me to shop for leather and ask the maker what he was doing 10 years ago! (let's get real... there are a lot of members here who show you what they want you to see and think - often NOT the actual situation). One humorous story, then one bit of suggestion .... Long while back, we were hiring for a remodeling company. I knew the guy running the halfway house, and he would sometimes call to see if we need help - helps us, helps the guy trying to work his way out of there, helps the facility, win/win/win. Kid filling out the application got to the part about criminal convictions, and was .... hesitating. Finally, I saw what he was stewing over and told him look, we KNOW you're from the half way house, so just tell me you weren't harming children or stealing tools from your last boss and we'll probably be okay That said, I HATE that "price perception" MARKETING CRAP. You know, where people take SUB PAR products and double the price, then tell you that you REALLY REALLY NEED this thing and ours "MUST BE" better because it's more expensive. Far as I'm concerned, poop with a higher price tag is ... still poop. BUT... check around for what goods are selling for, and you may want to RAISE your prices. Looking at https://danacanfield046.wixsite.com/website/shop I would have thought that pegasus thing would go for about twice that price. ENTIRELY up to you what YOU do with YOUR stuff, but I would have charged $35 JUST FOR THE LACING on that little bag with the blue rose. That's all I'm gonna say about that... I firmly believe a guy gets to charge whatever he wants if he makes it.

-

Mexican loop question

JLSleather replied to dikman's topic in Gun Holsters, Rifle Slings and Knife Sheathes

-

We do NOT have one for sale. We HAD one for sale, but my buddy spoke up said he wants it, and he gets the "buddy" price.... I wouldn't list it for sale at the price HE gets (including about 9 er 10 embossing rolls tossed in). So I was simply answering the guy's original question... YES, YOU SHOULD make them and list them if you can do it for $200.

-

Oh, here we go. There are half a dozen people making very similar holsters - close enough I don't know which is the "original" and which are the "knockoffs". https://www.bondarms.com/shop/holsters/leather-gun-holsters/bad-driving-holster/ Now, you can see that added strap sewn on goes around the belt, or seatbelt, so you don't have to thread it through a closed loop. Problem is, when the snap and/ or velcro opens, where does the gun go?@!! UPSIDE DOWN and perhaps TO THE FLOOR, eh?

-

Uh.. the ones I've seen were kinda like an EXTREME cross-draw type thing, where the gun barrel ends up pretty much horizontal, pointed pretty much where your car jacker would be standing if you were seated in a vehicle But the design, which has been copied by numerous "holster makers", is flawed from the start. Clearly they made it to be fast to put together and get out the door. It goes on your belt - or your seatbelt - by wrapping a piece of leather hooked to the holster around the strap, then attaches back to the holster. Been meaning to rework this for a bit now. Recently, fella called me and emailed me a pic and it immediately struck me as an issue. It attaches with velcro, and this guy said he would have preferred a snap, or both the velcro AND a snap. I guess the IDEA was that you'd have it on your seatbelt ONLY when driving (were you supposed to put it in a DIFFERENT holster when you get out the car?). Cuz it looked to me like if that velcro and/or snap popped loose, a guy could find his gun ON THE FLOOR. And his wife, who was on the other phone at the time, said that's EXACTLY WHAT HAPPENED. Most versions of this I see include a thumb break snap, but that's really for preventing movement in a holster that's NOT upside down Same fella - regular customer of ours - also bought the "pocket holster" for that "zombie" gun. He uses it, but we'll be redesigning that too. Amazing what some people call "custom" and perhaps more amazing there are people willing to pay money for some of that. We would have called that nearly $100 holster a FAIL and tossed it

-

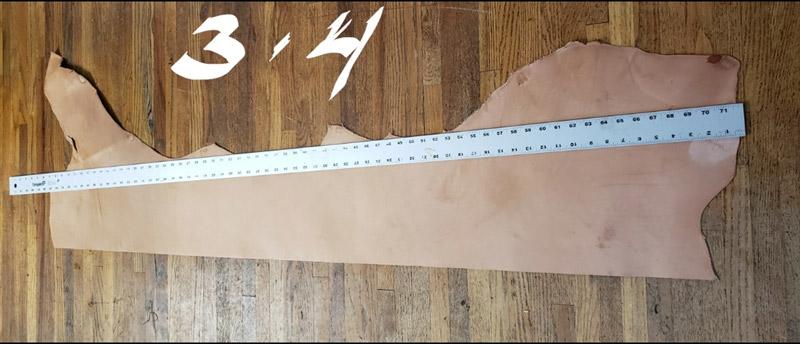

Okay then.. found 4 so far. The 3/4 is less lovely than I would have expected or remembered. But, normally we buy BACKS (bellies already removed) but these were a few times we just needed one or two sides, and was easier just buy the sides. Writing in pic is the weight of the leather, and ruler in pics is 6 feet long (meaning most of these are around 5 to 6 square feet of cow). Since the very bottom of a belly is NEVER much good, we'll trim these to fit in a 12" high box. We'll include all the leather, weighs 9 pounds +). We'd take $80 for all of this, shipped within the US. Cut one belt strip from each of the 7/8 oz and the rest of the piece is free

-

Got some bellies need to move out for the space. These are cut from Hermann Oak sides when they arrived. Grade A bellies, but of course they're still bellies. We cut them off and set them to the side right off - first cut on every side we use. Then we might use a bit for a belt lining, or a knife sheath, etc... but we don't do enough small projects to use these up. Clean leather (for bellies) good for sheaths, cases, bracelets / cuffs, gun slings (I use the backs of the hide for TOOLED slings), wallets, etc.. depending on thickness. Got 4 er 5 of these... easiest for us obviously to stick 'em in ONE box, so we'd take $20 each if somebody bought all of them. No shipping is free, but we'd SPLIT it with a fella (er a gal, too). Pics before long... I'll dig out what we actually have.

-

nearly a working model... "driving holster" for Bond Arms Snake Slayer over/under 3.5". Not sure i understand why a guy needs a "driving holster" when the OWB works well for driving, but these little things are quite popular and I ben meanin'a lay out something for about 6 months now! So a "day off" will mean letting a belt dry and prototyping this design ... close ...

-

From the album: Seriously ...

Sig 238 pocket holster for the wife of the guy who got the tan one (desert finish pistol). Yes, that's 2 colors in the initial. Custom purple with pink and red acrylics and "hot pink" thread. Because life is not all black and brown.© 2020 JLS Leather

-

- sig

- pocket holster

-

(and 1 more)

Tagged with:

-

I have one I'm selling - but not for that price. That's under my "buddy" price. You see 'em for twice that and they sell quickly - so if you can make one that works reliably and sell for $200 I would think you would stay busy for a bit. I recommend stop discussing and start doing. Has it been two weeks yet?

-

If you're just talking about marking the spacing, i like the wheels - they're fast and follow curves better than a multi-point punch. Down side is i don't know what spacing they come in - I've only seen 5,6,7 per inch.... though I suppose with a little common sense a guy could stagger the 5 per inch so it marks 10 per inch, 6 per inch could mark 12 per inch, and so on.... though 11 per inch would be tough Tell the truth... HOW MANY people never thought about running the 5 per inch TWICE to mark 10 per inch?

-

buckstitchin' must be "coming back"? they were sold out of these last year too. somebody helped themself to my buckstitch chisels years ago, never did replace them.