-

Posts

7,386 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by JLSleather

-

BUT WAIT>. .. if you order in teh next 10 minutes, you ALSO git dis one (just pay added shipping/handling)... for those who are more single stack 9mm folk ... Mag_P938_P1.pdf It's labor day.. no point workin' harder than a guy needs to today. ETA: noting that this was "patterned" with a sig 938 mag, but will also fit micro9, lc9, and xr9 (and a lot of others) but NOT the Glock 43 or the S/W shield 9.

- 32 replies

-

- passport cover

- notebook cover

-

(and 1 more)

Tagged with:

-

And if yer a 1911 mag carrier kinda guy (er gal) might plug this one. Same price Mag_1911_single.pdf

- 32 replies

-

- passport cover

- notebook cover

-

(and 1 more)

Tagged with:

-

Well, go on hit these too then https://www.jlsleather.com/diy/other-diy/

- 32 replies

-

- passport cover

- notebook cover

-

(and 1 more)

Tagged with:

-

How to get your products to sell well

JLSleather replied to RockyAussie's topic in Marketing and Advertising

That 'genius" in S. Carolina trying to sell holsters with my designs and a fancy story about his design skills offers like a jillion year "warranty". Problem is, if he look ya in the face and lie about the design, then WHAT IS his "warranty" really worth?@! -

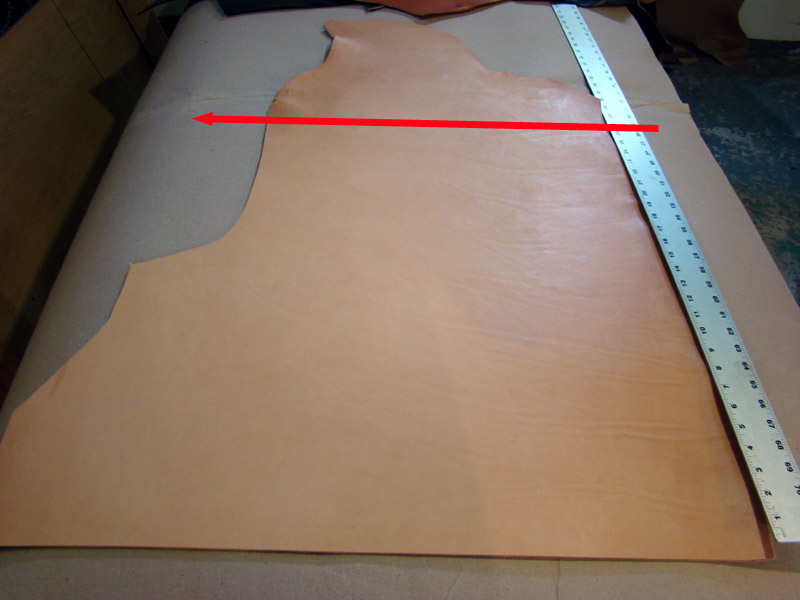

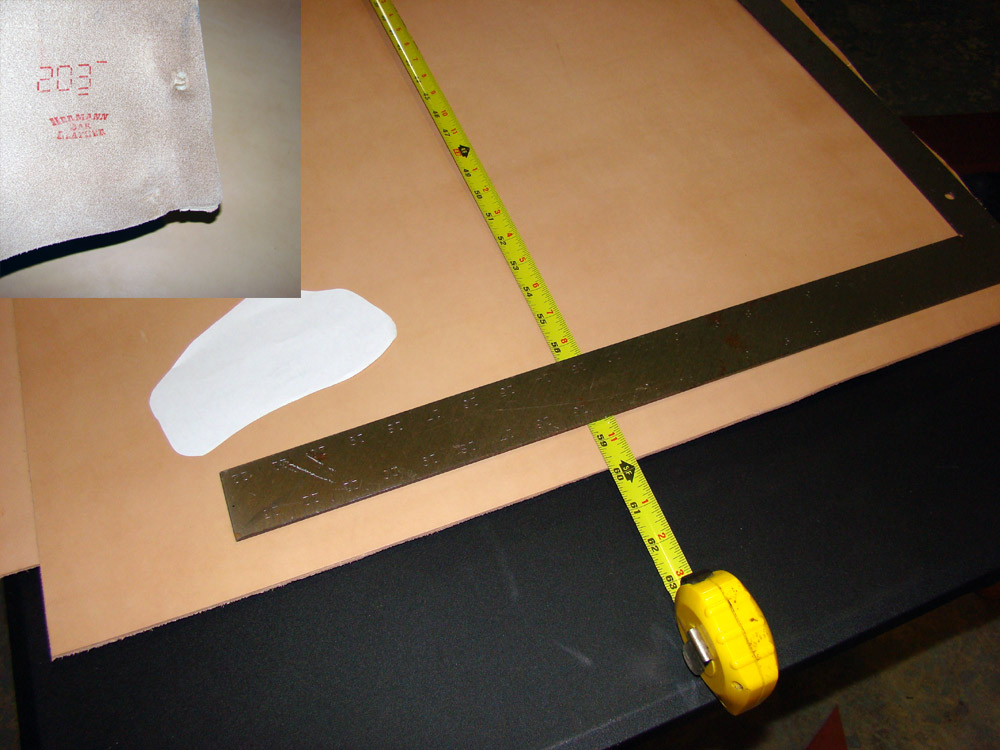

And you can see from these pics, that the shoulder does have some "shoulder wrinkles", but they don't span the entire width, and they aren't the type that make the leather unusable. Zooming in looks like that red line is about 26" mark, so I'm gonna say this piece is ... 7 feet? IF your leather isn't looking anything like the close-up, ask your retailer WHY NOT?@!

-

Was looking at some older attachments - my own - trying to find an old pic not found on the computer. Ran across this, posting just in case anybody forgot what great leather actually looks like. These days, there are 100's of retailers telling you and selling you stories about how great their stuff is. I guess we're supposed to take their word for it. Been going on long enough that many people think the stuff they've been getting REALLY IS great leather. And that's the reason for the post this morning -- just to point out that THIS is what great carving leather looks like. This is a "single bend"... started off as a "side" at the tannery, then the side has the belly removed (left side cut off) and the shoulder removed (bottom of bottom pic, by tape measure) leaving the butt. Pretty much ALL usable except where the clips were attached to stretch it (and somebody probably could use that too, I just dont). This is marked 20.3 feet, but that was with the shoulder on it. After cutting the "single shoulder" off, this measures 60" x 28", which math people will tell you is 11 1/2 sq ft. At $9.50/foot from Hermann Oak. So, this would be a $110 piece of great carving/forming leather. The holster pattern laying there give a fella pretty good idea how much we're talking about. No conclusions drawn here -- just pointing out that you may not be getting what you have been TOLD you are getting ... I just want people to see how it SUPPOSED TO LOOK. I dont believe I've ever seen a side of cow without some shoulder wrinkles.. right where the "bend" meets the shoudlers. But that shoulder has been cut off, so there SHOULDN"T BE ANY here....

-

Yeah, that's not a "direct drive" system... there's play in that shuttle/bobbin case area, which pretty sure is the "slap" you're hearing. Looks like the timing is fine... no issues there.

-

Would this be good to use for a stamp

JLSleather replied to PalmieriLeather's topic in Leather Machinery

Yup, it comes with a pair of inch thick plates maybe 3x5? So one on the bottom, leather (and a cutting block if you're cutting) and then the other plate. Pretty fast pump action too... no stalling your day. Handy. Punches out mag pouches like nuthin' -

Would this be good to use for a stamp

JLSleather replied to PalmieriLeather's topic in Leather Machinery

If a fella got a few more inches of space, it's worth gittin' this'n. https://www.harborfreight.com/6-ton-a-frame-bench-shop-press-1666.html I got it with a coupon fer like under $50. Stomps a 3" "maker stamp" and small cutting dies like butter through a hot knife. Er', sumthin' like that anyway. It's alittle taller, but still fit under the bench easy. -

Been a year folks. Just poppin' this up in case somebody missed it, or maybe the new guy didn't see it last time. STILL free

- 32 replies

-

- passport cover

- notebook cover

-

(and 1 more)

Tagged with:

-

-

How to get your products to sell well

JLSleather replied to RockyAussie's topic in Marketing and Advertising

'Hey, If you want me to take a dump in a box and mark it "guaranteed", I can do it - I have spare time.' https://www.youtube.com/watch?v=cf4C9ssuPjE -

-

1911 holster

JLSleather replied to Mattsbagger's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That's much better color -- and the copper is werkin' too. -

That depends on what you're referring to as "antique". Many people use an antique FINISH over tooling (I personally don't care for it, but I have some for when people ask for it). THAT project may have been done with an antique STAIN. Fiebing's makes a good one; there are probably others. Incidentally, Fiebings Antique Leather DYE also works very well.

-

From the album: Odds

Requested with slots leading and trailing. Personally, I prefer less width, belt space...© JLS Leather

-

Hey, I jus' only said TELL 'im I sent ya... didn't suggest it would do 'im any good ta mention me

-

Copying and copyright(ing) 'n' stuff

JLSleather replied to JLSleather's topic in Marketing and Advertising

I perceive that you... .......... like to talk. I will take my own advice now, and exercise my option of simply not participating. -

Copying and copyright(ing) 'n' stuff

JLSleather replied to JLSleather's topic in Marketing and Advertising

No, my question was.. what did you hope to gain by continuing to state your position? People will do what they will do. EVEN IF I chose to enforce i.p. "rights", I can only enforce MY OWN. And as for enforcing my own, I PREFER not to. I put a lot of attention to detail in my work. Most don't. So, if someone uses my design, he either puts that same attention to detail in the work (which most wont) or he SHOWS MINE to be superior, which only does me a favor. People see it's the same design, and set together mine clearly stands out. Copying me badly is like free advertising for me. -

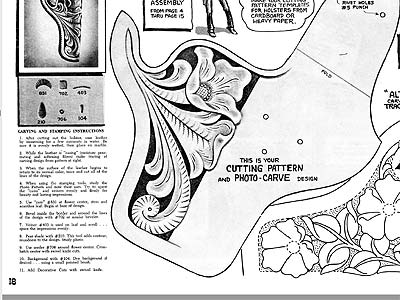

Okay, that was good stuff. Thread about copying others, closed just as I was delivering THE response. Just to good to waste, so I'll put it here. Doesnt matter if nobody reads it... Im usually just talking to myself anyway ________________________ Not enforcing a rule doesn't make you guilty of breaking it. People are shot every day. Prostitutes run rampant (and I hear many dressed like girls arent' even girls ). Illegals jump our U.S. borders at will with kidnap victims and drugs. The fact that I didn't stop them doesn't mean I "condone" any of it. There's a guy right now, claims to be from South Carolina. Got a web site selling holsters, CLEARLY my designs. When asked to make a holster he says he has available, he stalls a bit. When asked about my designs, he claims he's never heard of us (but the design IS mine, so ...). Point being, I don't "condone" that either. He's broken no laws, and really doesn't affect me, so .... I aint sweatin' one dummy. Even that one S O F T boy from TX usedta come round here quite a bit. Suckin' up FREE information, asking all the questions he figured he could slip in, then create a web site where he CHARGES OTHERS for that SAME information he was given for free. Now THAT is a bit abrasive to me. Come ask me for tips and tricks, then try to sell me a subscription to some videos where he shows those tips and tricks WE gave him! Hey, if you don't mind the guy is basically calling you stupid, go sign up! No matter to me. The "kicker"? He sold ("distributed" I believe is the legal term) patterns that contain the i.p. of OTHERS with only slight modification(s) and has the NERVE to add a paragraph about how its unlawful for YOU to copy or distribute "his" patterns! You might recognize this STOHLMAN design?

-

Don't take this as dismissive, but a couple things here. Im not sure I'm following what you're trying to do. You mean you're having difficulty with posts long enough to go through something else you're adding? And if this FIXES the problem, then is't $20 money well spent? Maybe I'm not following you here. Not trying to sound abrasive... just not getting the question.

-

Reminder from the bleachers ... any time a guy doesn't like the topic or general direction of a conversation, he of she always has the option of simply not participating. Folks, what point to bashing this guy? If you don't want to help him do whatever he's doing, then don't help. Not required. Whatever. There are millions of people ignoring this right now, and they're mostly doing fine.

-

Nuthin' smankey

JLSleather replied to JLSleather's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Even I hafta admit, this gal seriously knows how to plan a gift. This was a SO cool idea. -

Nuthin' smankey

JLSleather replied to JLSleather's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

'preciatecha Rejuvenated That old belt just SCREAMS "southwest US 1975" Yup, I'm gonna say that top layer was 9 oz.. overall it's about 1/4" thick. Lasted a good 30+ years without being sewn on the edges! Clearly machine stamped, but still woulda been a nice lookin' belt "in it's day".