-

Posts

7,378 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by JLSleather

-

Glock 42 Holster

JLSleather replied to Sofaspud's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Mind? Nah. I insist. I assume a fella won't help the next fella don't want no help his own self. [Some who sucked info from this site freely, then went and made their own site where they only share info for pay or other compensation, might have figured out by now why I have nothing for them] -

Not to sound course, but a quick and simple Google search turns up 9 MORE in addition to the two I mentioned.

-

I have dies from both Int'l Die and Tx Custom Dies. I suppose "reasonable" to one is not reasonable to another There are more places to have them done and I haven't tried them all, but I have talked with a few I didn't order from for various reasons. Both these places sent me the right shape at the right time for a price that was acceptable.

-

Glock 42 Holster

JLSleather replied to Sofaspud's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Wait.. WHAT?@! If I had some agendas, they'd sho nuff be fer sale! I've said it before, but FOR THE RECORD --- if you boys n gals got one them patterns used to display on our site, and the next guy needs one, DO SHARE IT. If you GOT one and ya DONT share it, PLEASE let us know here so we know who to snub when YOU want something -

Glock 42 Holster

JLSleather replied to Sofaspud's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Yup, been there. Fire way back when teach a guy QUICK... keep a copy off the premises. Some of the early days just gone forever. -

Computer Drawing Software For Making Leather Patterns

JLSleather replied to Blackey Cole's topic in Computer Help

Nah, I aint. But I wouldn't think that's drastically different than tracing on paper and then scanning the paper in to file. Couple issues with those- always has been. • Ya hafta keep the "pen" (or what yer usin') vertical. Any tilting/angling of the 'pen' and your pattern is off. • Guy has to consider parallax error, particularly when you're tracing 360° around. Illustrator (and others) certainly will work to make patterns. Just "offset" by some number of pixels (just have to be aware the resolution yer using). But the pattern will be no more accurate than your original shape (gun contour). 'Course, a guy could just make a line on paper where you know it's quite close, make the rig and test, adjust the lines as needed, then scan the finished result that works (which many of us have done for years). The advantage of having the GUN contour in digital is that I can (and do) then use that same file to make the "pancake" holster. And the "avenger" holster. And the SOB, and the pocket, and the shoulder..... or whatever else you wanted to make... much more easily. Like manufacturing 'stuff', the first one takes the longest and costs the most. Once the R&D is done, it costs less time and trouble to make the subsequent ones. I have been asked to sell these files on more than one occasion, but I don't know that people could afford what I would want for them. Then, if somebody was ALSO doing this, I might be persuaded to SWAP one now 'n' then ... -

Sig P365 pocket holster

JLSleather replied to chiefjason's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That 365 is definitely at least 'a bit" bigger than the 238 I made one o these not long ago, but can't find the pic(s). Sometimes depending on teh work flow I don't always have time to take quality pics of every thing (though, nothing goes out the door without at least a snap on the smart phone). Ended up larger than I would want in a pocket, but each his own. Color me nostalgic, but I'm more of a colt mustang kind o' guy. That does look like some elephant I've used in the past... but I've seen some water buffalo that was pretty tough to tell the difference. What's the rivet for? Got some type o' stiffener in there? -

Glock 42 Holster

JLSleather replied to Sofaspud's topic in Gun Holsters, Rifle Slings and Knife Sheathes

You covered a lot of ground with that post. Fiebing's saddle tan dye still works. I don't know what happened, but a few years back, I got a bottle of saddle tan that left a really weird residue. Smelled different too. Thought maybe it was old, or something. Well, I didn't think that, but I really like that color so I tried to think it was a fluke. Tossed it, replaced it, but next bottle was the same. Weird results. Didn't matter which piece of leather I was using. SO I stopped using it for a good while. Looks like safe to go back in the water JLS patterns. Part of why I took those down was people using those but expecting me to store them. I mean, I've downloaded stuff, then needed to go download it again. But when the same IP address is downloading the same pattern a dozen times.. guy is just cloggin' up my bandwidth 'pipes'. Seriously - it's free - just save it to your drive Glocks is like that frequently. Apparently, swappin' out the tooling retards production. So they made a lot of parts very similar one model to the next (like, chop the end off a G17 and you got the G19). The 'plus' side is that you get to do the same thing with the PATTERN you make. How many times have I told people if you already bought the G17 pattern, save your money and don't buy the G19 pattern -- just cut about 7/16" off the loud end and yer good Doesn't say great things about all those people who "love to help others" (so the story goes). Maybe you didn't ask anybody, but surely SOMEBODY saved that G42 basic pattern and coulda shared it with ya. Sadly, I find many people so terrified the next guy might get a break that they basically try not to actually share anything. Fair enough - guy isn't obligated to help the next fella - but it certainly makes it more public when "that guy" (who is not just one guy) then makes a video or a "how to" or a .pdf "to help others" but still doesn't include much (if any) actual useful information. All that said, pm me an email address and I'll send ya something. -

Computer Drawing Software For Making Leather Patterns

JLSleather replied to Blackey Cole's topic in Computer Help

Well, a "casting" would give you a 2d 'view' of the item, but it seems inefficient to make a casting if you already have the item - guy could just measure the actual item and enter in the drawing. In a CAD program a guy can use inch or mm measurements, and in a vector or raster program a guy could use pixels. The reason behind it is the same reason for a pattern of any other item you make a 'case' for. I can manipulate the same drawing over and over, and if the pattern gets worn or ruined it's simple to print another (assuming you have a backup). Some of it isn't that manual. Having checked, I can tell you that the Glock 19 is the SAME as the Glock 17, but about 12mm shorter on the 'business end'. So, obviously some models can be sped up by altering the drawing of one to make the other (not reinventing the wheel). Takes some of the tedious out of it. -

Computer Drawing Software For Making Leather Patterns

JLSleather replied to Blackey Cole's topic in Computer Help

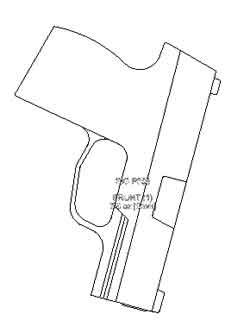

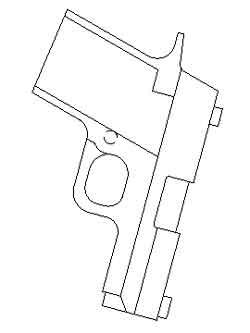

Above the trigger guard area in the pics the way they are oriented. So, the grip area basically. For a holster maker, the grip area isn't entirely immaterial, but it need not be as regarded as the rest of the pistol. Detail isn't required, just the size and shape of the contour. I put in enough details to distinguish it from others, but only where that detail makes an actual difference. So when somebody suggested a 'scan' of a gun, that interested me. Certainly faster than measuring and drawing. But, turns out this scan is to be taken as about as 'precision' as a photo.. which would be useless. The drawings above, if in proper scale 1:1, are all that is needed. Of course, you would need to know the thickness of the parts as well to make a 'case' that fits, but a 3d full model render would be excessive for this (though I suppose it would be good for instigating more useless conversation). I actually have the drawings (1:1) for quite a few guns. And I can continue to do what I've been doing. This thread (I didn't start) suggested a more efficient way -- but that appears to have been a dead end. No loss .. I'm not out anything there. -

Computer Drawing Software For Making Leather Patterns

JLSleather replied to Blackey Cole's topic in Computer Help

-

How many people missed the fact that it's 4" x 5"? Tha's great detail in that size pic (plus, never tire of seeing your use of color).

-

I certainly do recommend Andrew's short, concise video about making holster patterns. But this is the one thing he actually did leave out of that, and it's actually pretty important even if you're not enclosing the bottom of the holster. But I'll let Sam fill in those blanks if he cares to -- too many words for my existing available time. For now, lemme say that this can be done for small items before or after stitching. Small, I mean relatively thin - this knife would qualify, a Glock 21 prolly not. And that's a GOOD TIP from @RockyAussie ... (refreshing to see on this site).... veg tan CLAMP -- I like it.

-

Computer Drawing Software For Making Leather Patterns

JLSleather replied to Blackey Cole's topic in Computer Help

I think I got something like this fer bout .. maybe 85 guns ... Above the guard is a sketch. Below the guard is in ACTUAL SCALE. Not sort of. Not 'ballpark'. Not 'close-ish'. Always thinkin bout faster mode to this. -

Polyester versus Nylon thread ?

JLSleather replied to bcraig's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I don't see a visible difference - meaning they may not "match" side by side, but you'd be hard pressed to look at a thread and say it's nylon or poly (here come the "pros", who of course CAN tell, and also tell you which way you were facing when you sewed it). I recently saw a 3-ring binder I made in the 80's.. sewn with 4-cord NYLON thread. Holding up even better than I would have hoped. That whole thing about "UV resistant" MIGHT make a difference on boat tarps and car seats that will be in direct sunlight all day. On a holster, disregard that stuff. _________________________________ That said, it DOES sew a bit differently through a machine, though that's not the question HERE. Both are fine, but I notice that when I switch from one to the other, even though the sizes are the same the tension involved is a bit different. Not "worse" or "better", just different. -

As of 10/01, 43 of 50 states now collect sales tax whether they are located in your state or not. Are we all complying with fed law?

-

Copying and copyright(ing) 'n' stuff

JLSleather replied to JLSleather's topic in Marketing and Advertising

Tha's what I said. IF what you do is something that ANYBODY can do, then don't be surprised when ANYBODY does. Uh.. tha's what I said. IF what you do is something that ANYBODY can do, then don't be surprised when ANYBODY does. What about when they DID copyright it, and then it's reused and redistributed anyway? It's legally the responsibility of the copyright holder to enforce it. What do you suggest the rest of us should do when we see that? [That's rhetorical - thought provoking, but not requiring an actual response] Copyright 'protection' applies to the [re]distribution of the printed work. MOST of us have used Stohlman patterns. I STILL get asked to make some from 1950-something, which is before I was born. What i don't do, is RESELL THE PATTERN, which IS copyrighted (its printed right on the book, and has been renewed since then). Hey, copy my stuff... I won't care. Just don't copy my stuff, then offer to sell me a "how to" or a video explaining my stuff to me _____________________________ Footnote: EricA seems to think I was referring to him. Funny that. I'm guessing we're not going to see much the same way, so discussion probably not profitable 'adventure'. -

You shootin' a little wide --- that OTHER thread was about software, and people seemed more intent on killing time than solving issues, so I'm over and on to other things. Don't see any "cad" in that one, though. Looks more like downsized Illustrator - what with .svg files n such.

-

'Preciatecha Bob! Yer my guy fer sewing machine 'stuff', but since I didn't purchase the machine with you I try not to abuse the privilege. Got any of that black thread layin around..... and I'll burn the town of your choosing I'd be glad to pay for some LL point needles in size #23.

-

Anybody know how to read that crapra 4 manual? Messin' a bit.. don't usually use the "holster plate", since it's the same outside radius as the "regular" slotted plate, and don't use the "stirrup plate" because I can't be bothered to change the presser foot height and all that for the few projects that would benefit from that plate. BUT... I did give it a shot .. AGAIN. Now, the manual says put the lower feed back in, placing it 1/16" above the plate. Simple and clear. But manual also says put the shim in there (calling it the "inner race") with teh beveled edge "in toward the machine" and says "see below". But "below" doesn't exist, and the pic shown to the right (p 13) shows the OPPOSITE of what the text says (beveled edge is up). And on the opposing page, it shows the assembly with that "race" beveled edge OUT. So, WHICH is it SUPPOSED to be? [Note I ran the machine BOTH ways and did not note any significant difference either way]

-

Sig 938 Holster

JLSleather replied to AA3JW's topic in Gun Holsters, Rifle Slings and Knife Sheathes

-

Crutches isn't ideal, but if you have to use em might as well do it with style Now, some may say you have issues when your crutches match the house siding

- 11 replies

-

- saddle bags

- crutches

-

(and 1 more)

Tagged with:

-

First W&C order. And now....the wait

JLSleather replied to kellyblues's topic in Leatherwork Conversation

MOST of the W/C leather I've purchased has been quite good. The split is always what I asked for and the back needs no treatment at all. But, good to hear somebody admit this, too.. I've done some (I think) really nice projects with leather from Tandy. -

Computer Drawing Software For Making Leather Patterns

JLSleather replied to Blackey Cole's topic in Computer Help

My name is Jeff. That has nothing to do with the J in "JLS". Are you .. advancing in years?