-

Posts

7,386 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by JLSleather

-

Holster Patterns 'n' MORE stuff

JLSleather replied to JLSleather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Yeah, see tha's what I'm talkin bout rot cheer, boy 12 min and got more useful info than some folks turn makin a holster into a 5 part mini series -

Mexican loop holster... And belt

JLSleather replied to Stetson912's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Now you kNOW where that little fella is headed every time he gits a new shootin' iron- 23 replies

-

- mexican loop

- belt

-

(and 1 more)

Tagged with:

-

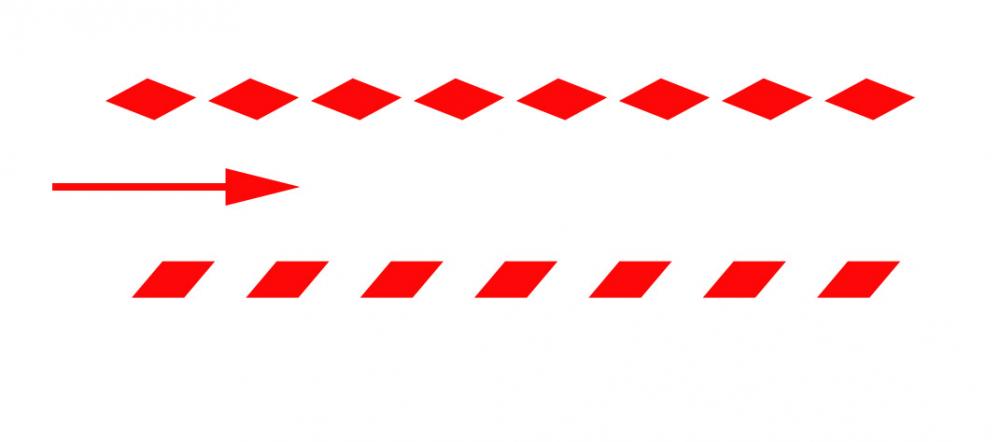

Well, I didn't mean to imply that I use tacks 'n' such IN LIEU of glue, more often thats IN ADDITION TO glue (or sometimes rubber cement). When I think gussets, Im thinking large notebooks, handbags, etc.. which I normally would glue first, then apply tacks/nails/brads, etc... as I stick the glue down. Rubber cement means more holders more often. As for the awl, keep the the flat side in line with the direction of the stitch.. Lemme see kin I do a quick graphic... There ya go. Same trapezoid (or is that a rhombus, I fergit), awl holes. arrow is direction of sewing. Clearly the top line is going to weaken the leather more (any time you're cutting or punching, you're weakening) and be more susceptible to teh stitching pulling through - esp with sharp bends and high stress. The bottom is made with the same tool, but the pressure is not in line with the stitch pull (better for now and later). These can be done with or without a groove.

-

No trouble. Main thing I don't care for is the way those "chisels" or "irons" pull out of the leather... pulling the leather on teh way. With quite thin leather, the effect is minimal, but it gets worse as the leather gets thicker. I get marking the hole locations with your chisel if that's how you prefer to do it. But I dont punch them. Either you punch a HOLE (material is removed) or you punch a slit (material is cut only but not removed) which is better than a hole, but still distorting the work. Having said that, I've seen some work where they guy doing it had become quite proficient with one or more "chisels", and made it look nice. Just seems like a waste of energy to me. BUT, I'm the one who doesn't care for that angled / slanted stitch. Perhaps that floats better in great Britain, along with that accent. No problem with the next guy doing it, no intention of trying to sway anybody one way or the other, but I personally like an awl no bigger than needed to get the job done (usually they're tapered, so just push it in far enough to come out the back side). I even buy machine needles that take that angled look out of it -- very straight lines. I saw a little fella about 5 foot tall roofing a house with a hatchet to drive nails -- and he was doing it as well and as quickly as I've ever seen it done. Wouldn't have been my choice, but he was so comfortable using it was like automatic for him.

-

I see Sam Andrews did yet another video. I came across it by accident. NOW, he's never gonna be purdy as me, and I couldn't personally listen to that tone for extended periods. BUT, he's got some very concise and to the point demo going on that folks wanting to make their own holster patterns might want to check out. GOOD NEWS (and one of the things I like about Sam) is he doesn't spend an hour getting to the point. This video is 12 minutes 'n' change, and involves more useful info that some spending an hour and a half ... But, Sam - friend - manila folders were big in the 70's ... but now there's 10 places in town that will sell you card stock by the ream https://www.youtube.com/watch?v=5PdKDmcmu8k

-

I don't know where YOU should purchase leather, but here are some thoughts I've had at various times, FWIW .. Hermann Oak and W/C both have some great leather. As a rule, an order from HO or W/C will be delayed by 2-4 weeks. Tandy has had some good stuff too - don't count them out, especially if you are close. If you can get something there that works for you, that's a win. Even if it's priced $30-40 higher, you'd spend that on shipping anyway and that way you get to SEE and APPROVE the leather you'll use (a BIG plus these days) plus you don't have the wait time. I have also purchased some good leather from Springfield Leather in MO. I would prefer to be there to see what Im buying, but not cost effective for me to make the trip. Delivery is pretty quick compared to the tanneries, though there is a substantial price markup for the convenience. Like Tandy, there is the advantage of "one-stop shopping", since you can also order your dyes, snaps, etc.. all from one place. Purchasing one order instead of multiple orders will reduce shipping charges, though again-- if you're using dyes there will be a 'hazardous' material charge, which can be considerable. All of which is yet another plus for your local tandy, where the "shipping" charge is the cost of gas in the truck and lunch for that cutie girl at the counter

-

No, "durability" would not be a trait I would advertise with acrylics. They adhere to a lot of surfaces and they are largely opaque, so the black underneath wouldn't "show through". But they are ONLY adhering to the surface and are not recommended for articles getting heavy use. For items getting USE, certainly DYES are better than PAINTS. The trade-off is that you won't be able to use DYE on black leather, as the dye will penetrate and the leather will just show the black. This is oversimplified, but that is the result. Having said that, some acrylics are better than others. Never used H.O. bridle, but I have used some very nice stuff from W/C. Again, the benefit of not dyeing it, but the issue of not being able to color beyond acrylic paints (and the longevity issue that creates). Keep in mind that if you make leather goods, then buying leather from a supplier who also makes leather goods is in effect paying your competition.

-

Well, without a lot of details, I could pay Alex a $60 DHL fee for faster int'l shipping and STILL pay less and get better results than SOME of those I contacted. A tip for Americans -- don't say "we respond in 24 hours" if you don't... sure way to take yourself out of the consideration.

-

https://am-leathercraft.com/ Alex. Shipping takes a GOOD WHILE, unless you want to pay international express. And while I like the IDEA of "buy American", I don't like it so much that the American can charge me about DOUBLE and NOT give me a better product. There's a lesson there

-

Look around for a local (or close to local) leather shop where leather is sewn. Guy can probably tell you where to get a GOOD sewing awl, and as long as you aren't "stepping on his toes" by offering the same thing he is, might even be willing to just sew them for you for a fee. Anybody can tell you wonderful pretty stories about what you "should" have, often followed by a sales pitch What you have there can all be cut easily with a strap cutter, and then you would of course need a hole punch for the rivets, a rivet setter. A bag punch or slot punch is handy for buckle slots, though it can be done with your hole punch and a knife (punch hole each end, cut out middle). So, for those: strap cutter utility knife or exacto hole punch sized for rivets awl harness needles and thread paints and brushes snap setter (if that's a snap on the front of the pouch) Since those are clearly acrylic paints, it would save time and space to purchase the leather already dyed black.

-

Kid looks like he dun that before Still not gittin' the whole "play some unrelated music and pan past a bunch of unrelated tools" thing, but I do like the way that old gal lays a stitch!

- 14 replies

-

- union lockstitch

- sew leather

-

(and 1 more)

Tagged with:

-

Yup, pretty much what I figured on the look. Think this is about as good as it gets in "binary" form without going to an actual 3D embossing plate ... pretty darn reasonably priced too. There's the "proof" this fella sent (click to enlarge). Fortunately, I saved a bunch of time and $$ hiring a "local" design guy ...

-

Yup, at that price ... so nobody wants ONE really tough on shipping costs -

-

Hey don't you have some holsters to sew?@! Leather spoken for!

-

I wouldn't know. I'm straight.

-

Single shoulders for sale - half off, but I want it cleared before Christmas. This leather is either black Wickett/Craig or natural Herman Oak. All split to about 8 oz give er take a tad. This is $9 and $!0 per foot leather, not off the bargain floor, but not as nice as some I've got in the past either. Expect the usual shoulder fat wrinkles. BUT on the other hand, I'm letting these go at half price to clear out the room. Show some interest in an IM or post here, as I separate them out. Guessing they'll all be about 5-6 feet each, so $30 each or $25 each if you're buying 2 or more. Or make a crazy offer on 5 or 6 pieces (25-30 feet?). I mean SORTA crazy, not batman crazy Shipping is neither free or included NOTE: If you use W/C drum dyed leather, then you know that the "chalky" buffs off easily when wetting or forming. If you are panicked about that, no need to purchase, eh? EDIT: I'm not using this for large holsters, since I don't like wrinkles, even natural ones. But this is an insane deal for a guy who makes exotic-covered holsters, or a sheath maker, or mag pouches, or wrist / ankle cuffs, etc...

-

colt officer dummies

JLSleather replied to JLSleather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Well, yah.. that's what I said -

-

Tooled Wallet

JLSleather replied to Tim Schroeder's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Oh yeah.. diggin yer heels in -- literally But them edges look pretty good for what appears to be a softer leather. -

colt officer dummies

JLSleather replied to JLSleather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Well, yes - kinda what I'm saying. Not teh right size. Either is it, or it isn't. And this one isn't. Could be just this ONE mold, though I'm not sure how they could vary that much and I have no intention of buying "dummy" guns in bulk to "pick out" the one that measures correct. If it's off by .010", or even .015", wouldn't matter. OR if it was UNDERSIZED by .06" a guy could easily build it up. Present condition, it might be fine for "training" someone who doesn't know guns not to shoot their foot, but pretty much useless as a holster mold. Well, for leather anyway. I don't do those holsters with a stitch line 1/4" or 1/2" away from the form (seems to be accompanied by a story to the buyer that they must not be doing it right) But again, not end-of-the-world type drama. Worst case, the little boys up the street have a new toy -

-

-

colt officer dummies

JLSleather replied to JLSleather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thinking more about the height, measured from top of slide to under frame, which on this one is about 39.7, depending on just where you measure. Seems about .060" tall.