-

Posts

7,378 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by JLSleather

-

Stored flat is best. Lays flat when working on it. Grain side down so you don't get a tan on the surface before you're ready. I've seen it rolled both ways, didn't seem to harm anything - long as it wasn't rolled too tightly.

-

Not sure the process, since it aint my thing, but I know it's done for making leather gloves in about 2-2.5 oz goat.

-

At various times, I've been known to fail to provide a reference for SLC, even when specifically asked (I understand patience and "community", but I think they kept a couple people on board a bit longer than I would have). But the other day, I did place a small order from them, and though it fair to state that went very well. The gal on the phone was polite, knowledgeable, and helpful. She verified my billing and shipping address and card on file to make sure everything was current. My order was processed immediately, the package arrived quickly, correctly filled, and correctly billed. This is how it SHOULD go. Whatever they did down there, they absolutely should continue.

-

Well, you have a clicker, so our opinions are just about useless to a guy who could simply TRY IT, and see if you like the results. Truth is, I don't like the results I get with flesh side up - that's using a shop press - like you'd see for pressing bearings 'n' such - and a very sharp die. The "break" on the edge is not clean enough. I am sure the appearance of the back (in this case the grain side) could be improved with a higher speed press. But I don't know that you could eliminate it. INSTEAD, you might consider dies made double edged. This is fairly common for items made in pairs that need to match. You "could" have dies made for "left" and "right", but that wouldn't always work out. Most die makers offer 1/'32" accuracy - so depends on if that will work for you. What I mean ..... you order left and right dies. The "left" die arrives 1/32" UNDER size, which is what the maker agreed to. And teh "right" arrives 1/32" OVER size, again within what you agreed to. But put the two together, and the right hangs over 1/16" all the way around. If you're going to fold it over and stitch it down, may be less critical. But if what you're making will show, maybe not acceptable. You could trim, or sand, or smooth... but that defeats the purpose of having the die. OR, have ONE die made with steel sharpened on both edges. Then place leather grain up, then the die, then another leather flesh up on top the die, and click. Spits out a left and right that WILL match (assuming the die isn't distorted). The places I've spoken with tell me that presharpened steel comes only in 3/4" height, which might mean a quick slight adjustment in clicking height.. otherwise, kind of a no-brainer.

-

That's going to depend on what it is you're wanting to do. There are some videos some will find helpful. BUT you've probably already noticed how many "leather videos" and "how-to" are just an ad for the guy in the video (sometimes by "experts" who clearly have no idea what they are doing). To begin, I suggest you identify the type of work you are wanting to do. I recommend checking out http://www.leathercraftlibrary.com/default.aspx? and https://www.youtube.com/user/TandyLeatherFactory/videos Some of that will be helpful to you, and some may not. Either way, it should give you an idea of the direction you want to go. Beyond that, I try to answer questions as honestly as possible. Videos CAN be useful, but pay attention to the CONTENT. One clear example -- I use the restroom every day. I could make a video, in high-def and 1080p , and add some background music, maybe pay a "celebrity' to tell you how great the video is going to be for you. In the end, it's still the same thing.

-

Graduation Present

JLSleather replied to MikeG's topic in Gun Holsters, Rifle Slings and Knife Sheathes

'Preciate the 'thanks' - glad to hear something I said did some good. -

3D printed mold guns

JLSleather replied to Madmax500000's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Absolutely IS doable. But not worth it to me personally. If I'm making ONE of a model, then just use the gun. If I"m making 50 of some model, then the "dummy" gun is about $1 per holster (and I still have the dummy after). Meanwhile, I could be making another holster or two DURING the time I'd be molding a gun -- so just not worth my time AND SPACE. My buddy built a new 36 x 130' shop .. but he didn't build it for me. More equipment, more materials, requires more room. And then the holster work (and belts, and wallets, and handbags, etc ...) is crowded and needs to adjust ... -

Anyone "self-identifying" is simply and quickly asked to leave. My party and I'll snub who I want to.

-

Graduation Present

JLSleather replied to MikeG's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Wait.. is that pen REGULATION?@! Looks good. -

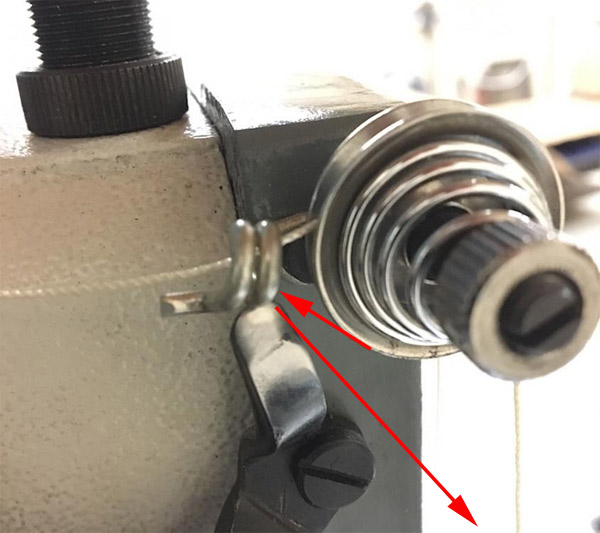

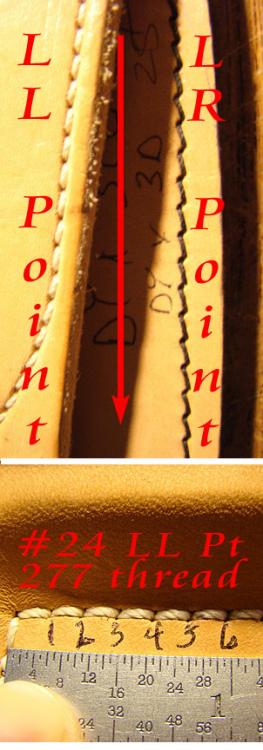

First one might save a fella 14 minutes of what I'm having for dinner and my dog's friend's hair color -- how to adjust bobbin tension in 30 seconds. Second pic an old one of so holster pattern testing, using #24 LL needle, natural thread in 277. Third pic is pure propaganda I would have preferred to use natural thread there (to complement the rope) but went with the dark brown requested.

-

Wait.. so to be clear .. what you did is this? HOW did I know the pink pig is a "she"? My little girl said so.

-

Why them holes look so big?@! Turn yer needle just a tad... rotate it in the bar. Looks like maybe a tad clockwise.. your thread may be a bit "behind' the needle. My buddy Robert had the greatest fix for backstitch issues. Don't backstitch. Turn the project around, stitch back in teh same holes in forward. Solved. No git ya a towel, dry yer eyes, and tell us what ya did for the next guy goes through that

-

Sure.. a number of places will sell you a CREASER embossing roll and the machine to use it in. Hand crank or motorized .. guess it depends on teh money you need to spend, volume you need to do.

- 8 replies

-

- bridle tack

- grooving

-

(and 2 more)

Tagged with:

-

sig 938 hidden loops shark

JLSleather commented on Bolt Vanderhuge's gallery image in Our Leatherwork Galleries

-

-

This should show the stitch well enough. Just by changing teh needle from LL to LR, with everything else the same and unchanged. The LL is a tight, straight stitch. The LR is a 'higher' - less set in stitch, with that slightly feminine, angled, "frilly" look that the girls seem to like Stitch length is the same, but the angle makes it APPEAR that the stitches are longer. The bottom shows the way teh LL needles close up the hole so well. 6 per inch shown (under a sig P938 slide)

-

-

Your stitches show heavy tension on the bottom --- meaning EITHER NOT ENOUGH TOP tension or TOO MUCH BOTTOM tension. Because the thread is not pulled up tight on the leather, I'm fixina opt for NOT ENOUGH TOP tension. I don't mean the holes, I mean the thread BETWEEN the holes doesn't look very tight. I know those needles and the thread you're using, and that don't look "sucked up". Try that thing I pictured. If'n t'was me, I'd back the WHOLE thing off 'n' start over. That's TWO screws above AND the bobbin case. Set you bobbin tension just so it has some "drag" when you pull the thread. NOT JERK the thread.. yer a equipment guy.. so think pulling the grader out the muck with a chain.. easy, even pressure gits er done, eh? Pull it in the direction it goes.. NOT against the thread path. Then adjust the top to suit. If the knot is centered, but thread not tight, then it's simple to snug up BOTH top 'n' bottom. I don't sew to see thread right there.. I sew like the top 'n' bottom is two elephants tug o war.. bury that thread in teh thing (almost)... By the way... you didn't want "light showing" through "big" holes. This is a 226 holster pic taken with a desk lamp pointed at it from behind. Size 24 Smetz LL point needle, 277 thread front and 207 thread back -- both threads supplied by Bob at Toledo Ind (link below). Yes, that's a fluffy pink pig on my desk, with her butt filled like a bean bag so she don't tip off. SO?@!

-

I like the idea. Material?

-

-

-

277/207 works -- I do it frequently. Still use a 24 needle ( LL ). Bobbin goes a little further, otherwise not much difference. Sewing holsters, 207 is plenty - but i use 277 for the COSMETICS.

-

Computer Drawing Software For Making Leather Patterns

JLSleather replied to Blackey Cole's topic in Computer Help

I looked for info in this topic too. Didn't see it just yet. Idea is, the "solution" should be EASIER and/or FASTER than a pencil and paper. If it isn't at least one of those things, then it's just making work. -

Yup.

-

Just gonna have to get over it and get used to adjusting it. WE ALL would love to have a machine that you 'set and forget" (I've actually heard from people who asked for it set up at the dealer so they never need to change it). BUT ... varying firmness in the leather, thickness variation, thread size and quality, and a GAZILLION other variables all affect the setting -- even just wear on the machine (springs lose some pressure, discs wear ..). Better to learn how to adjust it yourself. Ask questions, get advice, and remember what you saw and did. By the way,.. I wouldn't worry too much about "remembering where it was before".. for some of these reasons. But if you feel like that helps, a fine tip marker on the dial should be close enough. If you're a bit ocr, count the threads on teh screw.... (yes, tha's intentional).