-

Posts

7,378 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by JLSleather

-

Help choosing my first industrial machine

JLSleather replied to MStone's topic in Leather Sewing Machines

Really two words in sewing leather. Call Bob. Beyond that, some simple statements for FYI: I have one of those piece of cobra 4 things, and I wouldn't care to compel it to sew with thread smaller than 138 (I don't even sew with that on it, but it probably would do it). Sometimes seems like more is better, maybe more so when you're new. Turns out, it's heavier than I need - I have NEVER sewn 3/4" , nor do I anticipate that I ever will. I have owned (and should have kept) a Consew 206-RB5 (like Wiz mentioned above). Very reliable machine, no issues. Sewed #46 thread up to #207 thread well -- just keep in mind that 207 is THE top end. Confim with Bob, but I think the Cowboy 227R is the cylinder version of the same machine. Not too many doing leather next door to me, or I would have swapped my Cobra 4 for the Cowboy 3200 (let the new guy save about $1,000). Trade the lift capacity for the (possibly) better range of thread size. Needles and attachments are same for both machines, so that's not an issue. I make holsters, belts, sheaths, and some lighter 'stuff' and can't remember when I sewed anything thicker than 3/8".- 23 replies

-

First Pancake Holster

JLSleather replied to Hildebrand's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Looks like a good fit, and always "extra points" for using contrasting thread color Did you use the same leather (from teh same hide) for the panel? Looks a bit darker than the main front piece. Did you line it? Wondering why the stitch acros the bottom but not the top? Havent seen that grip before.. hmmm.. wonder if now Im gonna have to figger a holster to match those grips .... so many grips, so little time.. -

I don't much care for that holster. Looks.. idunno... unfinished somehow

- 24 replies

-

- youcantresistthis

- frisket

-

(and 1 more)

Tagged with:

-

If you're going to use DYES, I usually dye the whole thing the lighter color and then background the black over it (actually, I prefer the look of the chocolate dye there). But the order isn't critical. But you start using STAINS, it begins to matter which is first. Some stains tend to be resistant to dyes penetrating through them, and tend to be more opaque when applied over the dyes. In that case, you would want to keep the distinct colors separate. I don't like antiques, so I only use them about twice a year - when somebody threatens me with a check so big I agree to do it (I have been known to make TWO - one the way they asked and one WITHOUT antique - and they generally prefer teh NO antique when they actually see it). Point is, even after wiping off, dyes don't penetrate well over the pastes. In the case of dyed background, you would do that first, then antique the design.

-

Thread trimming scissors for normal guy hands

JLSleather replied to DonInReno's topic in Leather Sewing Machines

Yup, me too. It's just thread, and it's not even the part you're keeping - doesn't need to be beautiful, just gone -

Yup.

-

Help with thread size understanding and selection

JLSleather replied to Mhicks's topic in Leather Sewing Machines

Wherever you get your thread, know that even though the size on it is the same, thread from different manufacturers may not match. I say that because I had to find it out, nobody SAID that... you can get "277" thread from one supplier that is NOT the same size as "277" from another supplier. So perhaps it's a good idea to PICK ONE and stick with that supplier much as possible. Having said that, I like the stuff I get from Bob 'n' friends at Toledo Ind. 207, 277, 346, glides though the machine and the leather like it was LUBED -

I have 3-oz bottles for that particular green, because I use it often. Some shades (the red and blue) are not critical, and I use less, so I have 1-oz bottles of those. The brown shades, I use chocolate full-strength AND thinned - like on that fishin' wallet - full strength in the "cutouts" of teh horseshoe and thinned on the rest of the floral design. So I have an old bottle of dye almost empty, I just buy another and add solvent to the old bottle, so some of those have 2-3 oz of "thinned" in them. I had that happen a couple of times, where I mixed some "special" color for a request, did the project and had the customer all happy and going on about it.. then their friend decided they wanted one and I had to try to duplicate that color again after I dumped it. So I always mix more than I need, and save for a bit after, but I don't plan to keep every mix all the time. That shade of red on the welding logo was designed by the wife of the guy who owns the welding business... it's their co. logo, so had to be pretty durn close. Incidentally, the large rose handbag is from an old Al Stohlman craftaid design ... just painted on a purse because it was laying there ... Everything reduced is thinned with Fiebings Dye Reducer. Its' a no-brainer, being MADE FOR THAT. But I have used Angelus brand dyes also, and they are quite good. I don't generally keep a lot of that around, because they mix very well with other Angelus colors, but they do NOT like to be mixed with Fiebings dyes. I've had some WEIRD results trying to mix teh two brands ... one holster that should have been a brown tone turned out almost GOLD .. shiny like metal ... Maybe there's an answer in there somewhere...

-

Awwww.. shucks Tha's just some ole Fiebing's spirit dyes. Thinned the red about 10:1 and thinned the black (USCG Rating) about 20:1. And mix the green about 3 parts green, 1 part dark brown, 15 parts reducer (that green is too "loud" without teh brown tone). Here what I dun did with the PAASCHE air hose connector :

-

FB_IMG_1524372726008.jpg

JLSleather commented on LeHoang's gallery image in Gallery- Our Leatherwork

-

The VL (and the VLS) is a good brush. I've used em for years. Haven't seen a project I couldn't do with them, from relatively small detail to broad surfaces (though the entire back of a full size binder did take a bit longer than I would have liked to get a good solid dark brown). ONLY issue with the Paasche brushes, they use a different connector than a lot of other brands. Like SONY, great products but require SONY add-ons. I added a quick-connect on my paasche airbrush hose, so all I have to do is pop the whole assemly on or off. Not only good quality brushes, but they're indestructible, and replacement parts are available EVERYWHERE (in fact, I've been known to pick up a replacement needle right at hobby lobby 10 mins up the road). About any compressor will work, long as it will blow 20-40 psi. Some examples? Roughly 13 x14" over all. Done entirely with VL #3 Outer circle (in red) is 3" dia (VL#1) and handbag with large rose about 12" across (VL#3) Full size men's wallet (original art by Al Stohlman) with VL#1

-

3' x 1' x $5 is $15 per side? No machine shops? Simple face mill should take care of it. The set-up would maybe take a bit, but after the first one, should be able to "plane" (mill) them at about 5 min per side. Even at $60/hr it's still a bargain. That's $1 per minute .... thinkin' out loud here, that's roughly 1/2 the cost as weaver, but lets you duck the shipping charges. Simple job... and if they're using a CNC machine, even easier -- just need the new guy to clamp it down and hit the "go" button 4 times an hour....

-

And it aint even April Fool's yet ...

JLSleather replied to JLSleather's topic in Marketing and Advertising

Patterns aren't that difficult... only ONE INSIDE DIMENSION actually fits - for example - a 5" 1911 .45cal. Certainly there are variations in the cosmetics, but it either fits or it doesn't. But I'm never swayed by 'name dropping', or names at all. Everybody messed with leather knows who Al Stohlman was, even if they don't carve much. I don't know if he was THE BEST, but he certainly was the BEST KNOWN. Which is my point -- being widely recognized didn't make him any better or worse than if nobody ever heard of him. Holster makers have pretty much all heard of Bianchi, but I don't see anything stellar about his PRINTED work (I'm willing to accept the possibility he may have done things MORE IMPRESSIVE and I just haven't seen them). What's in a name? Nothing. When I was a kid, you couldn't eat breakfast cereal without seeing a picture of Bruce Jenner - 5 time olympic gold... blahblah.. Now he's ... WHATEVER he is. ... Which was the point about veterans. That "it's for the vets" thing carries NO weight here, but I've got that one a number of times. I've known vets who were great guys, doing their thing, raising families, minding their business. AND I've known vets who are now serving prison sentences. So that alone buys nothing. (It was a vet who blew up the OK city building, and a vet became the DC Sniper). COPS about the same way - and you see a lot of those around leather, particularly holsters. While some of them may have once been up to something commendable and worth recognition, many are now simply fat old men who have come to think they are owed something, or hope to use their history of not getting a job as some sort of "reference' FUNNY story -- a while back, I was barking by the street with yet another of those people unwilling to tend to their own life. Guy down the street walked over, invited himself to the conversation, and got told whatever is going on here was not up to him. And I admit, I deliberately added a bit of "smart mouth" in the tone. And the guy says, "in case you didn't know, I'm a cop". And I answered, "since I JUST MET you, I don't see where that could possibly be my fault." So, conclude: don't tell me your a vet, or a cop, or ex-cop, whatever, and assume that "earns" you something. I have TWO brothers-in-law who are cops - in different countries - and I wouldn't close both eyes around either of them. I may have brought some of it on myself. I have been known to sell things at or below cost to help a guy out, I've GIVEN things to people I thought they could use, so maybe people decided that I do that all the time. -

Not far behind you Ken. 'Cept no grandkids as yet. And I haven't picked up a guitar in so long I'm not sure I aint forgot (or at least got fingers out of shape). And my boat aint so shiny as yern. And I'll be catchin' more walleye than bass. And my wife aint welcome ta join me. Otherwise, SAME HERE ENJOY!

-

exactly why i never use it. Looks like what's left behind after the rain puddles dry up. I've seen some that weren't as bad as others, but I've never seen one I actually liked. In fact, I've seen some very good tooling basically RUINED by the use of ant-streak

-

Looks and sounds like you have a pretty good grasp on what's happening -- making good progress and seeing YOURSELF where there's room for improvement. And there IS improvement, looking "smoother". Two points to consider for the future that may be helpful - not just for you but everybody: I don't like the design so much, in teh way it ends. Repeating that pattern - as many belts do - would leave a MONSTER background area to the right of the flower, that I would prob'ly alter. and, for those who love to preach "custom" work and "handmade" and "one at a time" and "by hand" and "no machine"... ask them for one with the design reversed. You'll often find they aren't as "custom" as they claimed. For instance, A guy who makes this "by hand', "one at a time", with "no machines", ... SHOULD HAVE no trouble at all making this the same way - by hand, one at a time, no machines. No more or no less custom this way, right?

- 27 replies

-

- don gonzalez

- sheridan belt pattern

-

(and 1 more)

Tagged with:

-

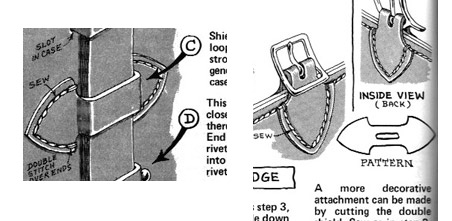

I might have misunderstood -- I thought you were talking about cutting out the SHAPE. That would require a "clicker" die, or what some the old folks might have called a "cookie cutter". Like this... These were made to quickly cut out parts for magazine pouches (gun clips). What you describe would be smaller than these, but same idea. With the type of press you have, set the leather in place, then set the die on top of the leather, then a metal plate OVER the die for the ram to come down on to press it down. Note you should have a cutting board under the leather to protect the die cutting edge.

-

OH --- IF I was purchasing a die for this, I'd be thinking EFFICIENCY. So I'd likely spend a few bucks more to have it made with the SHIELD ON BOTH ENDS. Stohlman shows that in the book, so no point going down that again, but this way you could use it with the shield both ends (over a ring or buckle) or simply trim one end if you want the "tab".

-

You can get a die made for not much more than the price of one of those handle punches. Now, if you don't have a press, probably not worth it, since the price of the press spoils the deal if you aren't needing one anyway. Like them boys that buy burnishers for a dremel, then go buy a dremel! Got a design in mind? Send a pattern to Sandy, ask her what she thinks (if you email it, you probably get a cost and time frame same day). Very knowledgeable (and great sense of humor). http://intdieco.com/index.html Ph: (800)856-0834 or (706)754-0921 Fax: (706)754-0922 Email: intdieco@windstream.net

-

Do we have a pic of how this purse looks 6 years later?

-

Those are great books to have - more for the PRINCIPLES than the actual projects. 50 years of experience in those. I designed those coast guard charge books with info entirely from that series.

-

Exactly. And ya know what's wrong with Patty Loveless? NUTHIN.

-

Go ahead.. all you folks so determined to check a video... tell me that isn't SEVEN FLAVORS of candy rot cheer... https://www.youtube.com/watch?v=TVL4mDFX3rY