-

Posts

7,378 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by JLSleather

-

I don't know where these people come from. Everywhere, I guess ... Can you make a pattern for a shoulder holster rig? I make holsters for veterans - can I get a discount on buying ALL your patterns? Can you cut me off just the best part of the hide so I don't have to buy a whole piece?

-

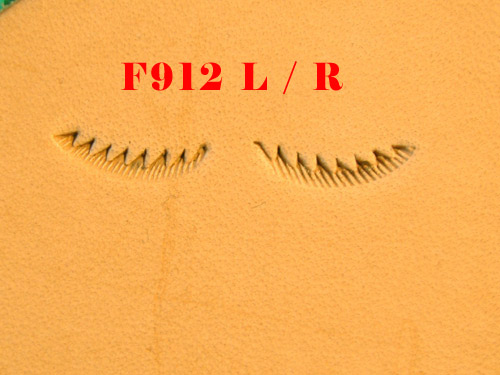

Somebody point out no price Shipped in US price $125 per set.

-

Weight Lifting Belt Seeking advice on thickness

JLSleather replied to Firewalker's topic in How Do I Do That?

Flesh to flesh, leave inside smooth. Bridle grain side to the inside, just buff (no finish needed). The belt in teh pic got 3 light coats of neatsfoot, couple days apart, otherwise no "finish". Each his own.- 20 replies

-

- weightlifting

- heavy duty belt

-

(and 3 more)

Tagged with:

-

Let's try that again, minus all the droning. Maybe even have the "for sale" section feature...you know .. stuff that's for sale? B - Makes small CURVED BACK holster. Originally designed P938 Sig, can make holsters of similar size by using appropriate stitch lines. PATTERNS for various guns not included -- that would cost more than the steel! C -- Makes back panel and REINF panel for CURVED BACK 1911 5" and 5" Operator. Accomodate Commander easily with bottom trim, and easily adapted to other pistols of similar size. More to come ... PM if interested, maybe the thread stays cleaner that way.

-

Weight Lifting Belt Seeking advice on thickness

JLSleather replied to Firewalker's topic in How Do I Do That?

These are generally a single layer of 13/15 oz, or two layers of 8 oz. MORE than enough. BRIDLE works great, since it wont absorb the sweat. If you want to carve / stamp it, I'd go with an inner layer of bridle and outer layer of tooling leather. And I've made them 6" wide for the CONFUSED when they specifically request that, but it's pointless really, 4" is "normal". Unless the guy is quite tall, I stick to 4" wide. (The guys who REALLY work out will tell you that the belt is for your ABDOMEN, not your back. The width is to SPREAD THE PRESSURE out when your AB MUSCLES FLEX, preventing hernia) IF you go with two layers, be sure to put a bit of curve in when you glue the layers - not flat on the table. Looks nicer, more professional, and most say it's more comfortable to use (inside is smooth). And finally, my PERSONAL preference -- much as I like tooled leather, I think it's easy to OVER DO tooling on these. Less is more. Here's one way, if it helps, have atter ... http://www.jlsleather.com/wp-content/uploads/2015/09/WB4.pdf- 20 replies

-

- weightlifting

- heavy duty belt

-

(and 3 more)

Tagged with:

-

-

Latest holster

JLSleather replied to alpha2's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I haven't had that problem, but fair enough if you 'n' sam did. I was talking about this, not the port ... Bolt's looks good, too, though, so apparently works with or without... -

There is no HO thread - HO doesn't make thread No to the sd9, sorry. Dummy guns available as I go through verifying my patterns -- make sure I got everything I'm supposed to. But I won't be selling these 1-0f, be more like sets of 4 or 5 guns ... If they don't sell that way, they store pretty well Haven't seen teh front panel as yet - this is the back piece and reinf panel for a 5". The front is not the same - used for curved holsters, right hand. Orig designed for 1911 but can be used for many 5" bbl. $125 shipped. Walleye net not included.

-

Back on Jan 30, 7 posts ↑

- 18 replies

-

- ho

- hermann oak

-

(and 1 more)

Tagged with:

-

FN 40 snap on holster set

JLSleather commented on Bolt Vanderhuge's gallery image in Our Leatherwork Galleries

-

P938 and similar size, right hand, front and back. Set B, cut 7/8 oz

-

Latest holster

JLSleather replied to alpha2's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I don't really care for that "line" put in there -- always thought it looked a bit ... idunno... desperate? But I like the general design I like to just shove the pistol a tad deeper, so that the horiz stitch line is well defined, then mold the trigger guard under the reinf panel (only)and the 'bump' in the frame. -

Cleanin' out good round here. I'm gonna have a BUNCH of blue guns at a FAIR price (not BARGAIN BASEMENT) and a fat girl you can have for the takin'

-

I didn't post any The pics in teh HO thread were already there, a few posts up- no point reposting them. So far, I have a pair of dies that make those "minimal" wallets on my site - that's a set. And I have a pair that makes a small holster, front and back. Think Sig 938 / Colt Mustang type dealio. And I have a pair that is for a 5" 1911 ... back panel and reinforcement panel. MAY find the front before it's over, but who knows ..

-

Cookie cutters -- sets. I'll have some cleaning out to do ... making changes here 'n' there. Yes, they are sharp with no nicks / chips, ready to cut when you open them. No, I'm not interested in breaking up the sets, even though some pieces can be used with other sets as well. Trim nail gun and walleye landing net in some photos not included.

-

Kicking this up, what with all the questions and comments lately about leather cuts and quality. This is what leather is supposed to look like - this isn't a "stellar" piece I hand picked by going through a stack , it's one of 10 standard HO leather from HO, all look about the same. Weird, I didn't get the new price list this year, or maybe I did and it's at the old address ..

- 18 replies

-

- ho

- hermann oak

-

(and 1 more)

Tagged with:

-

Newbie with questions

JLSleather replied to Tigdim's topic in Gun Holsters, Rifle Slings and Knife Sheathes

-

Newbie with questions

JLSleather replied to Tigdim's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Not much strength in belly leather - I don't use it. What is considered "acceptable" varies with the user -

Synthetic Leather right around the corner!

JLSleather replied to ComputerDoctor's topic in Leatherwork Conversation

Meh .. leather is (or at least was) about using what is available for useful purposes. This is more like making something "'new" so we can sell more stuff. One is a benefit to the planet. -

New Cowboy 4500 - Need some help.

JLSleather replied to internetcowboy's topic in Leather Sewing Machines

Definitely the foot pedal ASSUMING THE CHAIN doesn't have a bunch of slack in it.. -

Picture would make it easier, but that must be ONE ... THICK .... HOLSTER ....!

-

This comes with a machine: https://www.youtube.com/watch?v=Ui1A2CtxXnE And this is one version of a drop-down replacement (including one place you can get one): https://www.youtube.com/watch?v=vWd4FlRHv-Q&t=538s