-

Posts

7,378 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by JLSleather

-

- 27 replies

-

- don gonzalez

- sheridan belt pattern

-

(and 1 more)

Tagged with:

-

Shadow mark when using basketweave stamp

JLSleather replied to doublehbar's topic in How Do I Do That?

11 ounce garland rawhide mallet -

Custom Glock Holster assistance

JLSleather replied to bland's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I ain't madeno nuthin' fer the TLR lights... my nose goes in the air pretty quick when I see those. There was a kid round here did one looked good not so long ago... think the boy was in SD? Glock with TLR.. looked well done. Searching... Nope, turns out that was a different model with different light, so really no telling what I was thinking But sweet pea apparently did something along that same line... pictures removed, and I'm not sure what he charges for information. http://leatherworker.net/forum/topic/39502-avenger-with-rail-mounted-light/?tab=comments#comment-245420 -

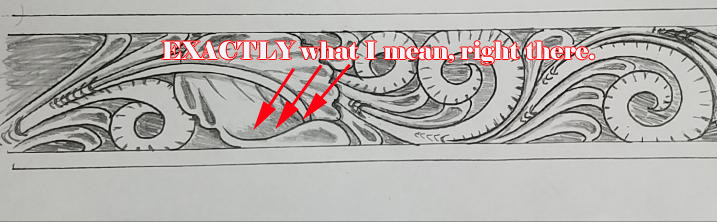

One more This will show how much difference you can get using the same design, same basic tools, just by putting the "BOP" in the wrong place. Somebody sent me this pic of a purse strap (bottom) and wanted another set made. Note how the tooling was "bopped" DOWN where it should have been UP, and the difference that makes. At their request, I used the same tools - with the exception of adding the "stop" tool to the ends of the stems.

- 27 replies

-

- don gonzalez

- sheridan belt pattern

-

(and 1 more)

Tagged with:

-

Well, that's why I uploaded the pic of the flower on my holster... I don't have the EXACT pattern you used - guess I could go download it but not today or tomorrow. I'll see can I find another example...

- 27 replies

-

- don gonzalez

- sheridan belt pattern

-

(and 1 more)

Tagged with:

-

Custom Glock Holster assistance

JLSleather replied to bland's topic in Gun Holsters, Rifle Slings and Knife Sheathes

More evidence that Simmons is a better marketer than he ever was a musician. AS for holsters, this CAN be done, but this is the type of situation where the owner should be deciding if it's a conversation piece to be put on a shelf, or should it be carried and used - in which case this is the type of thing making the case for kydex. -

Yup. You can use the same shader tool you used on the rest of the leaf ... or for efficiency - turn it SIDEWAYS and walk away from the line, getting lighter as you go away (down). As for the vein tools, I've always thought less is more -- let the leather show. So I usually use LESS marks, spaced further apart. This is a 'each 'is own' deal, though. Long as I'm doing all that talking, might do the backgrounding on teh blue areas

- 27 replies

-

- don gonzalez

- sheridan belt pattern

-

(and 1 more)

Tagged with:

-

Definitely looking better. DO fill in the bare spots in teh scrolls -- it's important to the over all look. Also tool the broad leaf (right side) to give some depth to the leaf, so it looks like a FOLD, not a LINE. And DO spend the money for good leather. You can't learn RIGHT using low grade leather.

- 27 replies

-

- don gonzalez

- sheridan belt pattern

-

(and 1 more)

Tagged with:

-

Book recommendation for beginner

JLSleather replied to Brahmus's topic in Floral and Sheridan Carving

I don't think there was much to be gained from "how to carve leather" (even stohlman admitted some of his early work could use some work). The other three have some great stuff, though. In the end, if you want to get good at carving leather, the main thing to have is ... leather. I'm not kidding - I've seen more than one person get so busy buying tools 'n' such they didn't have money to buy decent leather! Definitely check estate sales and the like -- I had one guy show up, saw my tool rack and said "I didn' t know you use those! We threw out about 100 of em cuz we didn't know anybody used em." Biggest thing is to use QUALITY leather. Folks talk about saving money (which is never a BAD idea), but the cost difference to move up to the good stuff from the not-so-much is only about $20-30 per side. I personally started out making belts. Money saving not the reason, but it worked out well -- since GOOD leather today for a belt is about $12-15 each, so when you booger one (you likely will) then you aren't out much. Other hand, a wallet carving back is even less money, so maybe there's that (remember, you have to also buy a LINER, though). -

MY Belt

JLSleather replied to Rolandranch's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Too heavy for my taste -- but should come in handy if'n a feller ever gotta pull a steer outda mud of git 'is truck down in some soft sand! I'd needa bringa young fella help me tote it I think yer right.. should be around a L O N G time!- 14 replies

-

Flat back holsters .. Pricing?

JLSleather replied to Boriqua's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I have NO answer for what somebody else should charge for their stuff - not my business, not my thing. But I will say that's a nice lookin' holster rot cheer... I like the stitch line a bit closer to the edge, especially at the top, but that does look good. -

How did you get into leather work?

JLSleather replied to Rolandranch's topic in Leatherwork Conversation

Mixture of interest, need, and contempt. I needed a weight lifting belt that boys at the gym could understand is not community property. I saw a guy making those belts, and it looked like it would work (though, he wasn't very good - just the only one around). And when I set up buying one, it turned into a zoo --- took a lot longer than he said, and I got tired of the excuses. When he suggested that he was the only guy around, so it was his way, I told him just keep that money, but I'll make my own. I ruined a couple of complete hides finding out how to tool at all. I bought books, tools, threads, punches, dyes & finishes, all manner of things I certainly didn't need to make a simple wide belt like that guy was making. I ruined some getting used to a swivel knife. I ruined some that were "mooshed" due to tooling way too wet. I ruined some not knowing what to expect applying leather dye - turned out not like paint really. I learned there really IS such a thing as too much neatsfoot on a belt. But I managed to get two weightlifting belts - one for my buddy - and a "jeans belt' for myself (which was certainly not beautiful). That was a good bit ago... -

Lookin' good, Kid - I like it. Great color, and the contrasting stitch is a nice touch.

- 22 replies

-

- rolandranch

- gun belt

-

(and 1 more)

Tagged with:

-

sounds steep, but haven't seen it yet, so ???

-

Also have an "E" which cuts holster front and back for Sig 320 full size and compact, and an "F" which cuts front and back panels for Glock 17, 19, 22, 23, 31, 32. These are not '50/50' holsters- the front panel is wider than the back on all sets. No point to contact this weekend, I am unplugged until at least Mon. Bargain hunters should perhaps shop elsewhere. In fact, to keep it simple, let's just say that ALL sets are $150 for the pair, shipping included.

-

WICKETT & CRAIG leather selection

JLSleather replied to pentelaravi's topic in Leatherwork Conversation

You're probably right, but I'm not actually sure just what it was you said HO does same thing .. they have "tooling" and they have "holster" and it's not real clear just what is the difference. But yes, the oak would likely be closer. I actually buy the natural BECAUSE of its light color. -

Oh, there ya go. When Ron said he had one, I thought maybe there was ANOTHER part I didn't get (but should have). Pay no attention ...

-

Hmm.. that piece of cobra I ordered didn't include that ...

-

Which leather burnishing machine to buy?

JLSleather replied to rivetandchain's topic in Leather Tools

Drill press. Running at maybe 100 rpm with a 1" diameter burnisher. Nothing pretty about it. But the edges are pretty nice. Particularly handy for belts and straps.- 30 replies

-

- burnish

- burnihsing

-

(and 2 more)

Tagged with:

-

Sometimes leather ppl get too caught up in looking at other leather. May at times be good to look at the ACTUAL THING you're trying to portray. https://en.wikipedia.org/wiki/Helianthus#/media/File:Sunflower_sky_backdrop.jpg

-

WICKETT & CRAIG leather selection

JLSleather replied to pentelaravi's topic in Leatherwork Conversation

Exactly - no point adding to that. I will offer this pic, though, showing exactly that. I took the pic with the HO on both "ends" of the pic, so you wouldn't think the color difference is due to lighting (it isn't). The W/C is TOOLING leather (not the skirting). As you see- the W/C is much more pale color, but they both hold the tooling very well. -

The mechanism that regulates that is anything BUT precision instruments.. more of a "bout so much" guess, really - and then even if it was flawlessly "tuned", it would still be reliant on the user moving the lever the right amount. You can use shim stock to limit the travel of the stitch length lever (top shim limits reverse, bottom shim limit forward). Get some scrap and some shim stock and that's not that difficult. Still, it's "set" with a collar on a shaft, so it may move again anyway. OR, if your part allows it - turn the part around and 'backstitch' in forward. OR, for large parts, leave enough thread at the ends, put a harness needle on it and "manual" backstitch a couple with a saddle stitch (the holes are already there). NOT to be misquoted (again) or misconstrued - I don't own that model, but I know a number of people who do and they are ALL happy about their choice. Were I in the market for another machine, I would pick one up myself.

-

DON'T wheel backwards - not the same as "reverse". Use the lever, or if the size of your project allows it and you're more comfortable, TURN THE PIECE AROUND and then stitch "forward" to "backstitch".

-

-

Weight Lifting Belt Seeking advice on thickness

JLSleather replied to Firewalker's topic in How Do I Do That?

Actually, that's not "flesh side out" -- that's somebody selling you SPLIT leather (the grain is gone). It's cheaper, so their margin is higher. Each person does his / her own thing - no matter to me - but anybody says he can alter 1/4" of leather by flexing his abs (with weight or without) is WAY 'full of it'. I don't know how a belt would "slide" or "move around" either, long as we're on that. A belt - once tightened - could only possibly move to a part of the body which is SMALLER than where it is put on. So the only person who would have a belt MOVING on them, would be the one whose waist is larger than the area above or below it.- 20 replies

-

- weightlifting

- heavy duty belt

-

(and 3 more)

Tagged with: