-

Posts

7,378 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by JLSleather

-

Leather stretches - and weather and heavy use aggravate that. Best bet - use good cuts of leather, preferably from along the spine of the hide, and subject it to getting wet as little as possible. Beyond that, you can gain some stretch resistance by using layers (a cord of three strands is very strong), or by lengthwise TIGHT stitching, or even by laminating with man-made materials (like webbing) which are made with interlocking fibers to prevent linear distortion.

-

Sandy is "da man", eh? Talented AND funny. Paper pattern is fine. Tell her Jeff sent ya (she'll ask 'Jeff who', but the service is still good!). http://intdieco.com/index.html

-

Just FYI -- $300 per side is about a 50% markup. A grade leather from H.O. tannery is about $200 per side ($8 per foot).

-

"Value" is subjective -- question is what's it worth TO YOU? I personally don't mind PAYING more AS LONG AS I'm GETTING more. The same stuff at a higher price is not "value", nor it less stuff at the same price. I like Wickett&Craig leathers, usually get the skirting leather and have them split to thickness I want. It isn't free, but it's quite good. Hermann Oak is also very good. Price is a little less, but there's a minimum order of 10 sides, if that's a concern. Both carve very nicely.

-

A few knives sheaths

JLSleather replied to Eddie Q's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Yer 'nuthin' fancy' sheaths look purdy darn good, actually. -

DW 357 "Stohlman" floral holster

JLSleather replied to plinkercases's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I always liked that one. I still get asked to make it on occasion. -

Proud owner of a Cobra Class 4 & question

JLSleather replied to Russ498's topic in Leather Sewing Machines

I got mine from Uwe - but I think he said he's not carrying those any more. https://www.ebay.com/itm/1SET-KG867A-suspending-edge-guide-fit-for-Pfaff-335-1245-sewing-machine/152966209333?hash=item239d7f1f35:g:Do0AAOSwcxVaxtlC https://www.ebay.com/itm/1set-KB-205-adapter-bracket-FIT-for-Durkopp-Adler-205-370-204-370-Cobra-4/152755036186?hash=item2390e8e01a:g:s1QAAOSwFFZbBSKK -

Guess he meant this fella ... https://www.etsy.com/shop/LeatherStampsTools?ref=seller-platform-mcnav

- 17 replies

-

- recommendations

- stamps

-

(and 1 more)

Tagged with:

-

I aint fixina make wunna those, but that was priceless -- nice work up get the attitude flowing to hit the gym this morning! Despite the pixelation, that was certainly hi-res enough for this conversation! That looks quite a bit like a thingie I had years back for POKER CHIPS, though I suppose back then it was injection molded (?). You have a point also about the view -- maybe transparent (or at least translucent) is good. The "gun 'n' holster boys might just buy that if you make it horizontal and make it "drop out" like a wheel gun cylinder ... Maybe that aint cost effective, though. But I'm purdy sure you folks got driftwood up there on the north beach.. maybe could pick up a chunk while up there rasslin' them crocs for the next project?@! Gotta stretch the bones .... 'preciate the talk!

-

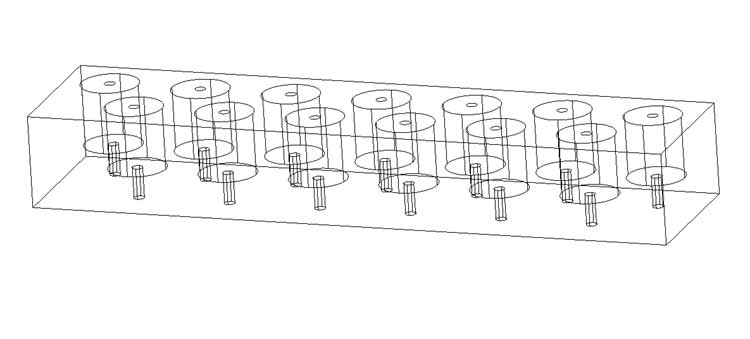

SO if a fella had a chunk o wood layin' out back the barn, could drill holes through the block spaced a bit like this. Then chase them same holes with a spade bit (yeah, I know -- somebody wanna git fancy and cut it out with an end mill on a cnc mill.. fine, whatever) 1.1" deep (or 1.250 deep, with a "thumb hole" on the sides of the holes). Which gonna look a bit like this (go ahead, somebody with all that 3d rendering stuff make a purdy pic ) #8 screw through the two end holes into the machine table to hang it, put the bobbins in and they don't unwind (no tape, no knot, no dust collection...)

-

Some things are flexible in the order, but I ALWAYS tool before adding linings. ALMOST always dye before assembling, and USUALLY apply final finish at the end. I have stitch groovers, but don't often use them - often opt for a CREASE instead of a groove (the stitch marker will still work). GENERALLY oil after dye (more often than not).

-

I always "temper" that "hand made" speech a bit. I've had people say my work "cant be hand made" because it was 'too perfect".. and you can find thousands of people on cutesy (etsy) claiming that their included defects somehow make their trinkets "worth more". Example - I love the look of hand stitching, but I'd rather see good machine stitching instead of poorly done hand stitching. Hand made is only valuable if it's WELL made. I don't charge by the hour, nor do I pay by the hour. I look at the item for sale, and decide if it's worth the asking price. Long stories about how much time was spent on it, or how much they spent on training, or how their Grandma makes her cookies, do not change the VALUE of that item. Long speeches about how long a guy has been doing it, or how much "experience" they have - also do not add to the goods. If a guy really is good at it, that will show in the work. If he's just been bopping out something for a long time, that will show too. And I've seen some "new guys" with real skills. In leather, what makes it "worth more"? I look for CLEAN hides, even dye applications and clear finishes with no streaks or spots, tight and consistent stitching, neat edges and corners, lace - if used - should be beveled and smooth. What DOESN"T add to the value? Stories about scars and brands making a project "unique". Flaws do not "add charm" or "character" to the finished goods. Calling defects (material or workmanship) "hand made". And the BIGGEST LOSER - TIME. There are extremes on both ends, of course. One guy wants a fortune for a simple little project because he took so long to make it. Sorry, I do not reward people for being slow, or inefficient. On the other hand, some other guy knows he isn't getting a huge amount for the sale, so his plan is to make it as inexpensively as is possible - lower grade materials and quick as possible. I personally don't hang out with either of those guys Now, I certainly "get" that something that takes longer will generally cost more, as things using more materials. But there is an "acceptable" time period for a given article. You can tell me you spent all week making that belt, every waking hour. But if I'm looking at a nice clean, solid leather belt done well with good materials, I'm auto putting that in the $60-80 range ... and no story about 100 hours matters. When I shop, I go by that old question: "If you cant TELL the difference, then why PAY the difference?" Convention says that "fair market value is what you can get". BUT in the end, it's YOURS, so YOU decide what to sell, and what price to sell at. So if "it feels like I am charging to little" then you are.

-

I wondered if anybody was going to point that out.

-

I haven't yet done it, but I will For the 'clones', I like the idea of a simple piece of wood. If my drill press hadn't pooped I'd be done Few things to get organized around here, and then I'll put one up. I suppose the 'trendy' thing to do is to post all over social poo trying to bilk leather workers into buying yet another item, or plans for an item. But maybe I'll just post a pic and a tip, and you can do what you like. Note you will need: something to drill with (hand drill might be easiest) small twist drills, 1/8" and 11/64" 1" spade bit (you could do with a 15/16" if thats what you happen to have) ruler and pencil block of wood, size dependent on number of bobbins retained couple of #8 screws x 1" (or 1 1/4")

-

-

Cobra 4 presser foot leaving marks

JLSleather replied to aaron8771's topic in Leather Sewing Machines

The fastest, easiest, most efficient way to not have marks is not to remove them, but to not make them in the first place. Suit yourself, but I find a piece of 4 oz scrap length of your hand (or so) prevents marks (there are still marks, but they're in the scrap piece, not the project) Spreads the pressure, much like a wider foot ... -

From the album: Stuff 'n' things

-

Cobra 4 presser foot leaving marks

JLSleather replied to aaron8771's topic in Leather Sewing Machines

footpad.mp4 -

Cobra 4 presser foot leaving marks

JLSleather replied to aaron8771's topic in Leather Sewing Machines

-

BG380 no laser, in chestnut brown

JLSleather commented on JLSleather's gallery image in Our Leatherwork Galleries

-

From the album: Stuff 'n' things

-

Rubber cement is temporary - it won't stay. Contact cement likely work, but not sure how flammable it is after it's dry. RENIA makes a water based product that should be fine, though I've never personally used it on cast iron For that application, I might try SUPERGLUE or GORILLA GLUE. If at some point you want to remove them, easy enough to cut the leather off and wire brush the cast iron.

-

Cons, hype, bull-oney 'n' stuff

JLSleather replied to JLSleather's topic in Leatherwork Conversation

Kinda IS the bottom line. I got a slightly different "marketing" speech, since the guy talking was a bit like me -- CRAZY intelligent but not particularly diplomatic Guy wants to insulate his walls. So he reads up, decides he needs to put holes in the walls, blow in the insulation from the top, filling as you go. Goes to the hardware store, tells 'em what he wants to do. So the kid takes him to the drill aisle. This one, simple version, is $19. This next one has reverse, it's $29. And this one is variable speed and reverse, $39. And this next one has a "hammer drill" function, it's $89. By now the guy is unsure which way to go -- he doesnt' want to have to come back, but doesn't want to spend more than he needs to. So teh question is, WHAT does he actually NEED?@! The vast majority of people answered that the $19 drill is all he needs - no need to get all that other stuff. But he doesn't need a drill at all -- what he NEEDS is HOLES IN THE WALLS, you were just told that a couple minutes ago. The rest was just "marketing" hype distributed by somebody who feels the need to sell you something HE has. __________________ There will be some who CHOKE at the thought that I'm offering something nice for LESS than they are - always been that way. I had people get MADDER 'N' A WET CAT when I poured my buddy's new sidewalk for a pork chop on the grill. More than one person bout went NUTS that day a couple kids showed up at the fishin' hole and I gave em some terminal tackle. I'm thinkin' SO WHAT if it cost me $5 to see some kids havin' fun! And that one fella got all irate when I smooched his girlfriend. Wait.. that one might have some merit Sometimes I say something to that "get what you pay for"... often just let it go - ya kaint fix stupid. I do know that I have never been in the line at the store, found something on sale, and asked if I could just pay the REGULAR price (cuz 'on sale" would make it 'worth less', right?). I have taken discounts for buying bulk. I can get leather from HO at $8, or I could get it from a retailer where it's jacked up somewhere between 20-50% more. At HO, or at the retailer, isn't it the same leather? HOW is it worth more?... Ahh... talkin' to myself now Incidentally, this is the holster he received (front).