-

Posts

7,386 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by JLSleather

-

First Holster...

JLSleather replied to ewayne53's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Yup, nice. I personally don't like the look of rivets, especially steel ones that inevitably chip and peel (solid copper don't though). The ends of the bullet strip can be sewn down without much trouble. STILLLLL, that's a nice lookin' belt rotcheer . -

the center division on that double mag pouch makes it easier to "draw' a mag, but not an accident ... the distance between is 'just' wide enough to use a tension adjusting screw + washer instead of stitching, but 'just' wide enough as not to increase the already considerable width of those things Just put your tension screw (or 2?) between the center stitch lines INSTEAD OF the stitch lines ... http://www.jlsleather.com/wp-content/uploads/2018/10/1911_DBL_Mag.pdf

-

-

Fauxligator wallet

JLSleather replied to Stetson912's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I have a $10 nylon wallet from Walmart Wife saw taht and called me.. well - nevermind what she said.... -

Well, each his own. Just remember, if you never go faster, you'll never go faster Lots of folks REALLY GOOD at going REALLY SLOW. Ask Wiz whre that video went.. think he was seewing rifle slings. Slow down at the turn at the tip, the rest took less time than typing this ! OH, your're in orlando. WIfe just left there a few hours ago -- good thing she didn't see that or i'd have it, and don't know where i'd put it. She don't care about sewing machines, she just like spending money on anything.

-

done all the time .. holsters to saddles. And yes, it does look pretty good. Throw in some inverted or "silhouette" carving, and ya got somethin' there.

-

Without a scale, I'd lean toward that being an lc9 LCP (v1) is barely over 5" long overall, if that helps

-

And of all those people buying the "flash", how many of them even asked what brand of tool you used to make it? What percentage - do you think - would NOT have bought your leather if you used a birch or plastic handled tool instead of walnut or cocobolo? Do we really think any of them looking at your work thought. 'man, I bet there was a nice brass ferrule on the tool that did this. I think Bill's point was .. if you can't tell the difference, then why pay the difference. If it costs more, it SHOULD be better. But costing more does not MAKE it better.

-

If it helps, I have purchased those "kits" and found out too late that the carving back and the liner didn't have the same number of holes.. so there was never a chance they were going to line up. Now, WHY I didn't check that BEFORE tooling... never crossed my mind. SINCE then, I have purchased those kits FOR THE LINER, pitch out the carving leather back and replace with my own, chase the liner holes onto the replacement leather. Sounds excessive (cuz it is) but better option than buying purse frames and the tools to install them.. when I only need one or two.

-

I like Ebay for that. I had a burglary years ago (and also a fire, but that's another story), and a lot of my tools were stolen. Insurance check isn't worth all that much when the tools are no longer available. Sad part is.. some crack head probably got $50 for the lot. My wife's friend showed up once, must have been a couple years ago. They buy stuff at auctions and estate sales, much like you'd see on tv show "storage wars",.. walked in and said "we didn't know you use those - we just threw out about 100 of em cuz we didn't know anybody who used them" Back to the point - I managed to replace many of them (the same version I had) on Ebay. Cost more than they did "back when", but the same quality, so no worries. Many people on there selling them, but you might start wth this guy ... https://www.ebay.com/str/proleathercarvers?_trksid=p2047675.l2563 I never met the guy (might not even be a guy). Havent seen ALL their tools, but i have purchased tools there which arrived in very good condition.

-

Don't remember ever dusting the saw blade before cutting the board It's the board that matters.

-

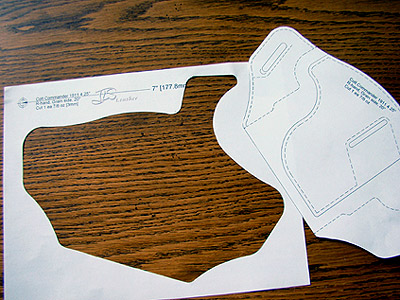

This is a "tip" from a while back, maybe worth refreshing. If you print the pattern, cut on the outside of the line, then the HOLE makes a great pattern for cutting off the hide. Lets you move it around and SEE the leather you're getting. The part you cut out - set it off to the side for marking stitch lines 'n' such. Making more than one or two? Print your pattern on 100 pound card stock. Most printers will run it just fine, and the pattern will last through quite a few uses. Spend 50¢ to save printing it again and again. Not as efficient as a clicker die, but it takes up far less room.

-

Workin on one (between other stuff) that will be about 2" narrower, and comes off the belt without removing the belt. Those glock double mags are BRICKS. The 19 is a decent piece of hardware, and there are about a zillion of them in use, but ya start talking about the 19 AND TWO mags, and you got yer pockets FULL. I don't facebook much.. they got so determined to "link" a business page with a personal page... basically make you a part of their commercial. I like to decide who I'm going to advertise But I do need to ramp up the web site, maybe get somebody else to write the "selling' end (which any of a bazillion kids can do these days) so I can do a bit more with the 'sharing' end. Been long enough since I uploaded a pattern I hadda scratch m' head a second to remember how I did that! Wayne has a set of cuffs with some sentimental value (yes, really) and he wants a formed case, with a snap down cover flap. Don't have the wood shop any more, and tough these days to find somebody to make the wood form (especially since I refuse to let someone I don't know be responsible for what isn't mine). Guessing by the way you have the leather in that stitching clamp, I'm gonna guess that YOU are the lefty ...

-

You're welcome, and thank you for pointing out the purpose of those downloads. Whole point is to "teach a guy to fish", if that means anything. Lots of folks have taken those ideas and gone on to make some of their own very nice designs. And besides, sometimes it's nice to bang out one of these simple little projects without re-inventing the wheel

-

That covers my "thing" right there. I don't use a round knife. But if I did, I would want one with quality steel - with some chrome in it for hardness and corrosion resistance - that keeps an edge well. Then I'm okay with the plastic handle.

-

Im right there with ya. I don't mind paying premium as long as I'm getting premium. Note that "premium" does not mean "okay-ish and comes with a pretty story". You may/may not have seen my "tag line".. 'Custom leather without the hype. Really.' I'm for thinking that if a guy has to spend time to tell you that it's "great", it likely ISN"T "great". I can tell you my oak burnishers do as well as my cocobolo burnishers, which I bought to see if there was a difference (there wasn't). I used to have an UGLY old truck with a snow blade on it. EVERYBODY talked about that truck, and the wife complained for quite a while for me to get rid of it. But that was perhaps the strongest pushing truck I've ever owned - just no power windows Since I pretty much never plowed snow with the windows open, I was okay with that. So when a smart-mouth kid with a shiny truck went on about it (I let him live, I actually like his dad).. I told him go look at that parking lot, snow all cleared, and tell me which truck plowed that one tonight. Which of course he couldn't do. And there's the test.... IS IT REALLY better because it's more expensive?@! Same here in the states, of course, which is exactly what he's referring to. I always say you can buy a Porsche to go to the grocery store. It WILL WORK, but you're spending a lot of money for "vanity". I have had people brag that they paid more than I did for the same item But I don't have a very high opinion of those who "tap into"... people who don't know better.

-

COBRA class 26 sewing machine.

JLSleather replied to ComputerDoctor's topic in Leather Sewing Machines

You mean the 26-18? I don't know you'll like it for 15 oz holsters. That's gonna be upper half of that machine's thickness capacity (don't it top out at 3/8"?), and I think that maxes out at thread size 207 (and that's pushing). If you're sewing wallets, checkbooks 'n' such, probably okay for that - then just hand sew the holsters (they're short threads anyway). Maybe the Cowboy 3200 is a better fit for you? If I had the space, I'd get one myself.. maybe after teh New Year ... -

New download, which is really a new old stuff download. 1911 DOUBLE MAG carrier, just a slight revision from the single, one most you boys dun likely already dun. Now, lemme say I don't so much care for these due to the amount of belt space they live on. Still, the price is good (the download is free) ... http://www.jlsleather.com/diy/holster-patterns-diy/ In the list, or maybe faster go on the right side, click on 'magazine pouches" above the oak leaves ...

-

How 'double'? More like a shield mag? That G19 mag is pretty beefy, though I never did much like the design - it was just something simple to git folks a start without an investment issue. I got some parts on my desk right now to test an alteration to that one. It works, and it looks 'okay', but I like 'em to bend on around a bit.. less binding (ideally, the tension would be the same on or off the belt). Or did you mean TWIN mags? I aint happy with the twin mags thing, either. I did a few, knowing I wouldn't be happy with how much room those types take up. Those of us with a waist size UNDER 40 .. put on a pancake holster, and a pancake dbl mag carrier, and aint much belt room left over! Still, a few have asked for 'em, so ... This ends up being about 6 1/2" wide when formed. Pattern up on the site in a minute, once i've cleaned it up enough that it at least isn't embarrassing There ya go .. simple and quick (take less time to make that sucka than it did to go through all that! ) http://www.jlsleather.com/diy/holster-patterns-diy/

-

Looks like the slot took a turn on the beretta, perhaps, but you clearly have a great 'eye' for designs SHOOT .. that reminds me - I still have Wayne's cuffs I haven't patterned yet

-

Yet another "plug" for a reliable supplier. These boys delivered - yet again - exactly what I asked for, exactly as described on their site, and did so quickly and easily. 'Dummy' guns, holster hardware, materials... and free shipping on orders over $99. https://www.knifekits.com/vcom/index.php

-

A good awl blade will MELT through 20 ounces of leather effortlessly. Almost don't notice it. I once sewed 13 - or was it 15 - weight lifting belts for a gym where the boys decided they all "had to" be hand sewn. Think basically rectangles about 4" x 60", so 125-130" of stitching each, at 6 per inch. What is that ... like 700-800 stitches per belt. I might have declined, but the check they were writing for the tooling haunted me into it Only discomfort was my hand shaped around the awl haft for too long. Sadly, that tool disappeared in a burglary, and I have NOT been able to find a suitable QUALITY replacement since. I've purchased and THROWN OUT about 15 others that turned out to be CRAP with a fancy MARKETING STORY attached (you know.. made in the USA, by a veteran, who only drives it on Sunday... blahblah). I don't care about "exotic" wood handles, or speeches about "ferrules".. I just want it to glide through the leather like they are INTENDED to do.