-

Posts

699 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Sanch

-

going more for a stitching chisel knurled handles are fine but this is taking place at my forge no lathe available so hot twist it's gonna be. @bikermutt07 I watchwatched the video about the same time you posted. to all replies thank you this will be fun I mostly am doing it just for wallets so the bar is set high cause the tines need to be pretty dang good biggest hurdle here.SPI will be dependent on my cutting wheel so many variables! gotta make sparks to make the goods.

-

tankx

-

Thank you for the reply. You wouldn't happen to have a link would you? Also as far as buying them I prefer to make a set myself. Call me frugal. Plus I have plenty of Steel that I know will outperform the cheap stuff I would rather spend the time making something that I can be proud of and proud to say that I made my leather goods with a tool that I made. I do all of my stitching by hand and so I know how an awl acts in my hand and if I can reproduce this in a pricking iron then I will be golden.

-

Okay so I have never used or actually held a pricking iron and I'm wondering about the spacing between the teeth. Is the measurement that's being given for instance 3.8 is that from tip to tip? Or is that the space in between each tooth? Also how long should the teeth be ? So for those of you that have them can you please give me some dimensions metric would be fine ! Yes you guessed it. This will be my next challenge to make a set of irons out of the L6 that I made my other tools from. My plan is to make the blade out of the L6 and to make a handle out of half inch square iron which I believe to be wrought iron. I plan to mig weld the blade to the handle after I heat treat and temper the blade. I also plan to put a Twist in the handle both for ornamentation and better grip I figure the handles would probably be good at six inches in length. So any information shared on this subject would be greatly appreciated I'm having so much fun making tools and I'm wondering what the outcome of these will be thanks for any and all replies.

-

No it it's not exhaust tube it's actually pieces of a elliptical Runner that I had Salvaged. The pin on the bottom actually will drop into a knuckle that allows it to spin and tilt I'll post a picture of it later

-

I made a 7 layer billit with some 1084 at 2"wide x 3" long and forge welded it successfully. you sir are correct it is a pita hand forging it is WORK.

-

can't say but the sawmill confirmed the blade manufacturer and the steel. it is L6 or 15n20. From what I'm being told and from my research on the blades that I'm using it's more than likely L6 Heat Treating and tempering process is fairly close to the same and I have yet to have a blade fail with the process that I use so I'm satisfied

-

lol! thanks!

-

Don't blame you one bit!

-

I'm working on a new stitching horse/clamp it will be adjustable in many different ways this is the beginning of it hopefully my ideas will pan out. It will have its own frame and seat just similar to a stitching horse only the seat will be from a motorcycle. It is a gel seat from a Sportster a le Pera it was sitting around gathering dust so I figured what better thing to use then a motorcycle seat! So here are a couple of pictures hopefully it will work out the way that I want to. Of course it's all metal and the Jaws will have leather wrap. As always comments and questions are welcome. and here is another picture of what the tensioning device should look like. Hopefully it will work out if not it's been a blast making it so far! there are still many modifications that I have to do to the jaws the silver perpendicular round rod will allow it to rotate on a knuckle of sorts then there is another joint that will allow it to tilt. At least that's the concept for now. This one is going to be a standalone unit unlike my other one that clamps to a table.

-

You're doing a whole lot of extra work with that Dremel you should be able to make all of your stitching holes with an awl but as they say to each his own! There are many ways to skin a cat

-

I'd like to know what brand of paint and your top finish method if your willing to share. I used ETAC textile paints on a tank cover for a custom build they are "heat set" the longevity on them was great top coat was also acrylic based and heat set. I wanted to edit my original posting but it was already too late so I just quoted myself

-

Biker billfold

Sanch replied to Sanch's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

The pattern for this wallet exists here on the Forum in the patterns section if it's not there I believe it might be in how do I do that section! -

look at my "issue solved" thread

-

What kind what kind of longevity are you getting from this acrylic paint? And are those seats actually being used? Or are they going on show bike?

-

hmmm. Wondering if they got the issue straightened out. I read through the whole thread. Sounds like heat treating went bad on a batch. And that is very unfortunate but easy to do. I have never purchased from Jeremiah Watt, the tools are out of my price range at the moment because I can make my own (recently discovered) of course they look nowhere near as pretty but found that it is a doable task and time consuming. So to all of those disgruntled consumers living in a fast-food world be wary of the stones you throw just my two cents. Until you actually try to make your own by learning the various processes that it takes to produce something such as the tools that we use it's very hard to appreciate the work that goes into them. That having been said anyone providing the tools should stand behind their work quality control should be stringent. And no I am not throwing any stones of my own. Does this change whether or not I will purchase the tools of course it does but I can also say there is no magic unicorn so who knows. For the price of the full set of blades plus a handle it may be worth the Gamble. Really let's take a look at this in retrospect all of us at one time or another purchased tools that we knew were not up to the standards of what was being considered high end tools. So think about this when you talk to a customer that wants to pay way too little for your time and work of one of your products they are comparing it to something that can be purchased elsewhere they are not taking into consideration your time nor effort. So to all of this I say if they had a try it before you buy it how would jump all over it unfortunately that is not the world we live in not even with the products that we make ourselves! In the aforementioned thread I seen no responses from Jeremiah Watt and I would also like to say that is not me throwing another Stone. I'm sure he will take care of the issues.

-

Again with the white dye. They all look great!

-

Love it. Which white dye are you using and what is your application method I'm assuming airbrush.

-

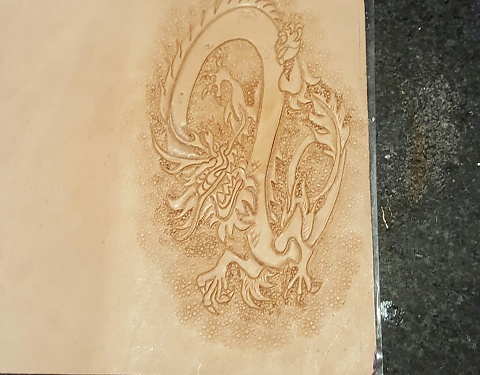

Okay so this is a biker billfold that I did fairly recently enjoy as always comments questions are welcome! Oh and I just did the billfold the guy did not want a chain and a belt attachment as he had a custom one. And one final shot of part of the tooling

-

Okay so recently yes I made a couple of edge bevelers had a blast doing it. They do work and they are effective and I only lost a little bit of skin on the tip of my left forefinger while making the handles! LOL! So I watched the review that Nigel did and have read a few other reviews but I wanna know what the collective thinks how many of you own them and love them or not? What kind of mileage can one expect from these tools I understand they're not 3 figure tools but I also understand that you can strop them . I was very close to pulling the trigger on a full set tonight just because, like I said before I like making my own tools but this set really intrigues me so any feedback is greatly appreciated.

-

Need help picking a color for the edges of a holster.

Sanch replied to Bolt Vanderhuge's topic in Leatherwork Conversation

You could Sunburst that thing with an airbrush whatever color is your choice but I would do it either dark brown or black -

lol! I am well beyond the beta testing stage these are my personal knives I will never make any for production only onesies and twosies here and there!

-

Has anyone made a weighted hdpe milk carton mallet or maul?

Sanch replied to ContactCement's topic in Leather Tools

It's definitely doable and HDPE is fairly simple to work with. Although I choose Delrin. For this application you wouldn't have to worry about inclusions in your melt at least not as much as if it were something more structural such as take for instance a slingshot frame. Watching the video if you're going to go through that much trouble you need to ensure that you get a good melt all the way through because if you don't it will Splinter apart also instead of trying to press it into a square mold like he has or why not press it into something round like say a section of copper pipe with a cap silver soldered on one end and another cap to do your pressing on the top the reason why I say copper is because copper will heat up much better and you can put it in the oven and continually fill it as the Melt is happening also you could monitor it to make sure you do not get any of the inclusions that I was telling you about. And actually for the cost of the copper pipe you could probably just save yourself the trouble and by a mallet already made LOL! Maybe some black Iron 2-inch ID you would definitely get a better press out of that anyway cuz she could add more Force to it -

are you referring to the one on top of the cutting table or the one on the layout table? yea I fabbed both of them. well I have always had a train wreck so decided I was getting a hand on things rather than the mess.

- 22 replies

-

- work area

- leather working bench

-

(and 2 more)

Tagged with:

-

cool, you anywhere near Elkton? I used to ride out to bike night every Thursday with my Indy. I hope to be doing it again soon I got to get my old Shovelhead back together.

- 22 replies

-

- work area

- leather working bench

-

(and 2 more)

Tagged with:

.jpg.d60258221c476480a6e073a8805645bb.jpg)