-

Posts

699 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Sanch

-

Recent stuff

Sanch replied to Sanch's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks!- 4 replies

-

- business card holder

- belt

-

(and 1 more)

Tagged with:

-

Recent stuff

Sanch replied to Sanch's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks.- 4 replies

-

- business card holder

- belt

-

(and 1 more)

Tagged with:

-

Ok and now i can comment...i like to wait to see how you work things out brother! (Just like on the swivel knives) the embellishment looks great man fantastic job yet again! Very nice way to add personality and some feeling to your tools! I think it's funny how you went on the side of a big old heavy Maul, and I went the exact opposite direction! I will explain and show pictures later! Although mine is a whole lot less embellished! Again man great job!

-

Here's a couple of pics of recent projects. Enjoy and as always, comments are welcome. The wallet is what led me into making the skiving knife that I recently posted. Unfortunately I didn't take any pictures of the wallet interior and rolled edges. all of the carving for the set was done with this . I'm sure some of you will recall it is one of my homemade swivel knives which has become my recent favorite .

- 4 replies

-

- business card holder

- belt

-

(and 1 more)

Tagged with:

-

T-88

-

Ya the end is sharp all the way across perpendicular to the handle, there more better?

-

Thanks! Oh! Duh! Lol sorry bro cranial flatulation on my part!! Yes only the rounded corner of that side is sharp! Simple marine grade epoxy no need for pins no stress on the scale..

-

It actually has a chisel grind so one major bevel then a secondary bevel and the back side is flat

-

Thanks, as far as the beeswax versus carnauba I have no clue Beeswax is what I have so that's what I use and it hasn't failed me yet on any of my knife handles I should say on any of my leatherworking knife handles for any of my other knives that I have made and use and see hard use I use something totally different for a final finish on the handle

-

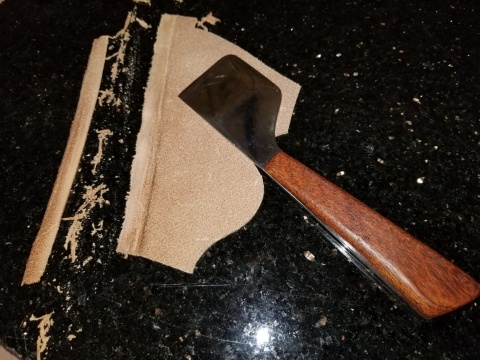

Because most of my projects never needed to have the edges skived more than what I could do with the cheap safety skiver I never invested anymore then the $9 that I think I spent on it. But recently I found myself in need of a better way to skive the edges for wallets so after some research and watching some YouTube videos I decided on a combination design which I think turned out okay. It is very functional and the steel is good as I have used it for making my 1/4 round knife and several other knives that I have. Anyhow here it is. The steel is L6, the wood scale is jatoba finished with pure beeswax. I may in the future remake the same design as well as a couple more just to see if they work but for now this one works great thanks for looking and as always comments are welcome!

-

My latest with a little help from a laser

Sanch replied to OLDNSLOW's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Looking real good there man I guess you figured the laser out huh? Good job! -

Home made Stainless Steel Burnisher First Stage.

Sanch replied to ContactCement's topic in Leather Tools

How do you intend to use this as a burnisher please explain -

Can't believe the JW edgers didn't suit you did you get a bad set? Hell send them to me i love mine they work perfectly.

-

Sorry for the all to late reply I've been busy at work! To answer your question its dealers choice you could just slip the hose as is over some flat hardwood that would be the way I'd do it that way it doesn't lose its integrity and you have 2 sides one for green rouge one for white. Good luck and thanks for the offer I'm sure someone will pick up on it.

-

Brettun's Village Punching/Pounding Boards - anyone ever used?

Sanch replied to epiphanist1248's topic in Leather Tools

This has been a subject of many opinions but I think for what it's worth a smooth (no lettering) 18 wheeler mud flap if I remember correctly was an alternative offered up.- 1 reply

-

- brettuns village

- pounding

-

(and 2 more)

Tagged with:

-

You must really love that mallet, I think you did a fantastic job adding your feeling to it and hope it feels as good as you hoped it would there's nothing that compares to making a tool your own great job so far can't wait to see the Turks head finishing the the wrap! I have a couple of old Osbourne mallets that are at least 15 years old? they don't get used as I have 3 main mauls that I made/use.

-

Check out this thread.

-

Sorry for slow reply Exactly what @bikermutt07said but it can happen on any blade not just a convex (Appleseed) edge. And he is very right It can get technical quick!

-

@Mjolnirlooking great friend

-

Either or will work fine, try them both see which one works better for you. The best advice that I can give you in this area is to use at least a 24 in Long strop backer "plank" preferably a hardwood. No pine.....You want your working surface to be at least 18 in Long.

-

Yea that's easy enough to make, and I almost made one when I was forging my own straight razors, but no sense in doing such. Here is the one that I made specifically for everything that I sharpen. I no longer use the cut throats so the strop is in my leather working area one side is grain side up which never gets used as this side was for straight razors alone. The other side is plain and simple. I do not like the way that a 7 to 8 oz piece of leather can roll your Edge. So after much research I used a piece of duck canvas, when sharpening the straight razors this side was used just prior to polishing the edge on the leather side. Here is a picture of the canvas side which is mostly used. The canvas is attached to a cheap piece of straight Poplar.also when it gets "loaded" as you see the center portion of mine is you can scrape it clean using a "junk" knife like my Tandy skiver. This would destroy the leather it doesn't phase the canvas just cleans it so you can reload your rouge... so IMHO canvas is so much better... oh and for the record fire hose is by far superior than duck canvas but its unavailability to me prevented its use.

-

Yup yup same tape here they have it at Wal-Mart sports section in colors.

-

Very nice, that's one thing that I've only tried once wood burning never appealed to me although I did some lettering a long long time ago great job the Mallet it looks nice.

-

Ruger LCP IWB Holster

Sanch replied to alpha2's topic in Gun Holsters, Rifle Slings and Knife Sheathes

This man's opinion. That is a fine rig.. no need to line it, that just adds to your cost of making it. -

The bearings I had, were salvaged from a small conveyor I found. Thanks!!?