-

Posts

699 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Sanch

-

Finished Sheath for Customer!

Sanch replied to YinTx's topic in Gun Holsters, Rifle Slings and Knife Sheathes

@YinTx great sheath Sorry this is one time I coulda done with the rule being broken!! P.S. Your spirit stitch is great.- 36 replies

-

Leather Gun Belt Double Stitching

Sanch replied to BattleAx's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Was it stitched by hand??? Regardless it looks nice and clean! Now about the lil cracker jack ya got there is it full of lead shot?? -

That is some very fine tooling sir...I zoomed as close as your photos would allow and you were METICULOUS my hat is off to you.. your technique of laminating the front panel is intriguing, if I had to take an uneducated guess I'd say after your meticulous tooling you laminated it flesh to flesh then stitched. Flawless execution beautifully dyed as well. The golden yellow, is it acrylic based? it's very vibrant!

-

These 2 have no bearings at all.

-

Jeremiah Watt horseshoe brand look him up

-

Hydro/ vacuum formed knife sheath

Sanch replied to ComputerDoctor's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Okay first of all I don't know if he posted this here for constructive criticism, or maybe to get some advice? First off 4 oz is too thin for a knife sheath in my humble opinion, it will get floppy on you . secondly I see no mention of any type of welt being used, if that blade has any type of Edge at all your stitches will last all of maybe two or three pulls, or the sheath itself being so thin will catch no slack....Thirdly if your Stitch line follows the Contours of that knife at the distance it should 2X the thickness of the leather you will never pull that knife out of that sheath! Good luck and let us know how it goes -

People who have inspired you in your leatherwork.

Sanch replied to machinehead's topic in Leatherwork Conversation

Thanks! -

People who have inspired you in your leatherwork.

Sanch replied to machinehead's topic in Leatherwork Conversation

I for one can say that this forum and all of the members here both active and no longer active have contributed to my success and some failures (because of my interpretation or lack thereof lol!!) So to list all of the names would be kind of difficult! Starting from the mass-produced cheap leather goods I have seen, all the way through to having seen breathtaking work has inspired me in one way or another. As far as the claim of being self-taught I am guilty of that claim in that I have never sat down for any type of formal training with anyone, I initially started with the intent of making a custom motorcycle seat for my FLH which you see as my avatar. This led me to where I'm at currently, making my own tools and making custom pieces. No I do not have a huge following nor do I prefer one, but I am thankful to all here from the beginner all the way through to the most experienced! -

What Do You All Do When You Find Someone Is Copying Your Product?

Sanch replied to LLWork's topic in Leatherwork Conversation

Re front pocket wallet and designs etc etc what I find very interesting is that you don't hear about any big clothing industry arguments pertaining to the shape of front pockets themselves! I can understand if a person reverse engineers and CLONES a product and makes a profit in doing so. But to make a big issue over a shape? It's kind of like arguing over who came up with bottled water first...or whose idea it was to carry a pocket knife with a clip "wait you have a clip on your knife, that is my idea you can't do that!!" Bla bla bla.... anyhow... People will be inspired by others! WELL SAID SIR. -

Horseshoe brand...

-

Most of my slickers are Delrin..hmmm 15 min on the lathe and should be a blue to come up with somthing but the SS had to be tried as well. Thanks again Thanks for the reply!

-

1st off. Very nice work! Secondly thank you for the answer 88 views later lol!!! Yea i don't need to source them though i made a couple out of SS just was curious thank you so much though!!

-

Who's got one and uses it regularly? With what results? Post pix...

-

Lol yea yea Custom tools for custom leather...

-

I do not. Sorry.

-

To each his own... fidget spinner how many do you own lol!

-

Search for liquid latex and you'll find it cheaper in larger quantities i purchased a quart abour 5 years ago for approximately $12 and its still good. Kept in cool dark cabinet.

- 24 replies

-

- youcantresistthis

- frisket

-

(and 1 more)

Tagged with:

-

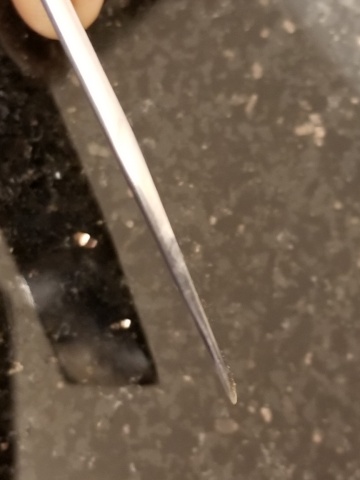

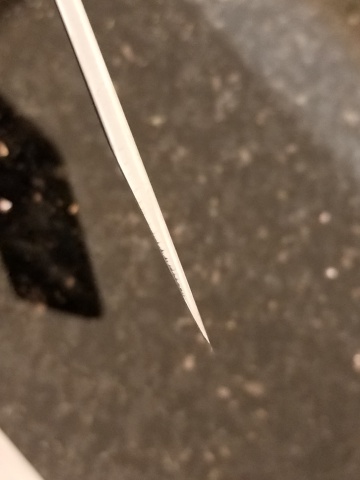

Thanks, Fixed height. Thanks, look for micro bearings, these have none only tight tolerances and synth grease. IMHO I feel that bearings and spinning the saddle for 2 minutes straight thing are over hyped selling points, as long as you can get a smooth action from the barrel you're golden. The blade angle, sharpness, and polish are key. I prefer the smooth finish over an knurl finish anyday day even if the knurl and is not aggressive. No issues at all for me. Thanks for the kind words.

-

Made a couple of new swivel knives 100% hand made no purchase shtuff.. 6061 aluminum body and saddle, brass body and 304 SS saddle. Both sporting 4140 HT blades made by me..needed somthing skinnier than 1/2" and 5/8" that's what my other hand made barrels are, so I decided 3/8" was best. Enjoy and as always comments are welcomed.

-

Very beautiful work.. and i'm sure the technique has its merit, although hardening the edges of a cut wouldn't suit my style of tooling in most cases. I can see where it would be worth the added effort, and it obviously works!

-

A lot of work (for me)

Sanch replied to MorningStarL's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Very very classy looking work I like it clean, simple great job! One question why did you choose to not do the edges and black just a curiosity, and for my take I think black would have really set the color that you chose or that the customer chose off very well nonetheless again very classy work!- 12 replies

-

- knife sheath

- commission

-

(and 3 more)

Tagged with:

-

Thanks maybe we can talk Thank you.

-

It's L6. Thanks for the kind words.

-

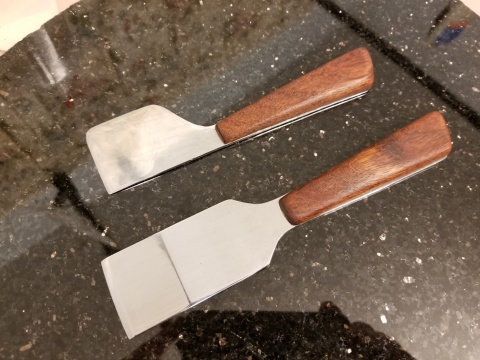

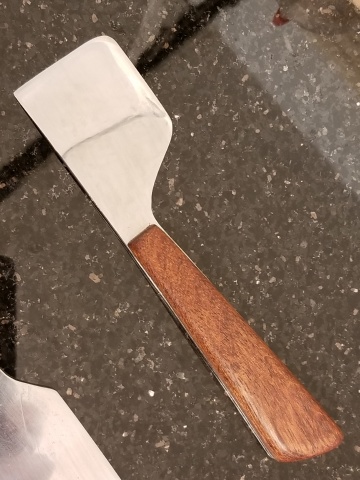

Okay so here they are they both came from the same parent blade and they both have scales from the same parent wood only like most siblings they are different LOL!

-

Ok so it seems this was missed by me...i gave.. yeah that's right gave @OLDNSLOWone i made a while back after modifying it to accept a 1/2" diameter shaft, he may still have it and can tell you about the performance...i never got along with it...i prefer Delrin, and have made a few. But I always find myself going back to burnishing by hand with Delrin. It is slick and non-porous you would think that it would perform the same as stainless steel which is what the one that I gave away was made of 304 stainless steel to be exact 1 inch diameter. Although I would be interested in finding out how well aluminum would work my only fear and reasoning behind not doing one in aluminum is that there would be transfer to the leather from the aluminum. If anyone knows the wiser please inform me cuz I would like to know