-

Posts

4,410 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by bruce johnson

-

Hand cranked fudge wheel, I've seen it called a hand crank wheel welt press too

-

I'm probably the one you are referring to with the 3/32" of cut. That is how I am starting to describe edge tools. Good or bad, at least it gives some sort of reference. There are NO industry standards for size numbers anymore. It used to be that every number corresponded to that many 16ths of an inch. That standard went away years ago and now the numbers from one maker to another don't match usually. I am starting to just give the tool maker's size number and widths of cut so something/anything will relate. Size wise? some people like a heavier rounded edge and want a 180 degree rounded side edge. Others want a tiny bit edged off and a mostly flat side edge profile. Comes down to personal preference. I've got a tutorial on my website how I sharpen and strop edgers. I still do them mostly like the tutorial even though that was years ago - https://brucejohnsonleather.com/tutorials/

-

I've got a drawer with at least a dozen of the black iron vintage versions hoping for some NOS blades to float up but likely will never happen. Blades could be fabricated but not worth the time and effort vs return for me. Most people of the people I deal with want the modern version with disposable blades. The cam action of the top guide helps keep the different lace thicknesses flat and the unit is easy enough to replace a blade on for the folks that have trouble sharpening. I don't extend my blade up nearly as much as Handstitched I guess. I have mine set so the sharp edges are within the frame and cam bar on either end. I don't have as much blade edge but can switch the blade end for end once before it either gets stropped or tossed.

-

They are flat bottom edgers, not rounded.

-

Differences between these two Ferdcos??

bruce johnson replied to Teradee's topic in Leather Sewing Machines

H was their high lift version. Not sure what frame they based the grey one on. Ive had Juki marked 2000s and white Pro2000s. -

Trouble adding EPS to cobra class 26

bruce johnson replied to Alexfisher's topic in Leather Sewing Machines

Vince would be the one to talk to now at Cobra. -

Imperial Tex Tan Cutter Restoration

bruce johnson replied to Rudegal's topic in Saddle Identification, Restoration & Repair

I've already written and deleted two replies and here is version three. I am answering the questions out of order. 2. the whitish finish. After maybe 50 years and who knows what it was treated with during it's life - could be petrified Saddle Lac or who knows what. Pretty much any solvent will be hard on the leather. Might be some sort of acrylic too 3. Since you didn't mention the glue looks like crystallized tree sap, might not be dextrine but again who knows what they used back then. Not drying and still sticky could be some reaction of solvent glue and foam or just rubber cement residue. 4. Anything else to know about these old TexTans? I'm maybe a little biased. One of the higher points of my younger life was when I was 14 and made enough money from a summer job to buy a used Price McLaughlin saddle and I never had to ride that damn TexTan Imperial saddle on the "form fitter" tree again. Not everyone in my family shared my enthusiasm for the upgrade but they were not the ones riding it. Later on I was in college and working for a trainer I bought two Billy Cook BW tree cutting saddles. They weren't much happy about that either. My candid thoughts are there isn't much helpful to learn from this saddle. I don't meant to sound hard, but this saddle is dated and old and built to price point with production techniques. The seat won't be right without pulling the guts out of whatever groundseat there is but then afterwards the seat likely wont stretch down into place. That cantle is nearly impossible to sew back without a ton of experience. How decent will the rigging be after this many years? -

It depends on which maker. The new Craftool and entry level Amazon blades are not that great but workable. As you move up the ladder generally the blade material and grind quality gets better. I've had some Asian made Amazon-ish swivel knives with pretty good steel and some were not. I've got one friend who uses a blade made from a point file that Chuck Smith made years ago - awesome blade and he strops it on his pants to just wipe it off. He said it has never been resharpened after years as a carver in a shop. I believe him and have used it some. I told myself I wasn't going to name names but here goes....Top of the heap for me is Bob Beard - hard to get and expensive - something to aspire to, not start with. The cobalt blades Chuck makes now have really good reviews from a couple people I respect. LeatherWranglers, Red Ox (Gordon Andrus)are similar in price to Chuck Smith and can't go wrong with any of them. Barry King, Clay Miller, and Gomph-Hackbarth (Lonnie Height) make good knives. The skinny on this - If I was outfitting a new bench - for the mid level price Barry King would be where I'd start. He's got a moderately priced swivel knife in more yoke and barrel choices. He's got a selection of blade choices. He'd be way more consistent than taking a stab at Amazon. He can give you advice on what he thinks will work best for you. With his pricing you could actually buy 2 or 3 swivel knives from him in different barrel and blade setups for the price one of the premium knives from another maker. If you decide to move up the food chain in a couple years, Barry King tools hold value more than the lower ends. In the meantime you will have learned to sharpen and maintain, what you like and more of what your carving style is and what you need to do it.

-

there are a few things to think about with a swivel knife - blade and the handle/yoke plus what you have for sharpening and how well you sharpen - then factor in budget and expectations. blades are all over the scale in quality. Obviously you can expect the more expensive they are generally the better edge retention. A Craftool blade can be sharpened to the same edge as any of them but it probably will not maintain that edge as long. Still passable if you have skills to sharpen correctly, frustrating if you don't. The less expensive come in two flavors - adjustable and nonadjustable height. Even the highest adjustment on some may not be enough for some styles. the diameters are maybe two choice but generally no choice. The yokes are usually one size fits most. The upper end makers have choices to optimize the tool. They offer choices in yokes - size, width, amount of curve, profile. Fatter fingers - more width, smaller fingers smaller yoke. If you use the flat of your finger then a flatter wider profile yoke is more comfortable. If you press at the joint of your finger - narrower rounded profile. If you have bigger hands or lay your knife back then generally a taller barrel. If you stand your knife more vertical or smaller hands then a shorter barrel. barrel diameter is crucial. 1/16 inch can be a big thing. smaller hands generally smaller barrels. If you are doing long straight lines or gentle curves a larger barrel will help track straighter. If you are doing tighter intricate curves (Sheridan style) then a smaller barrel has a faster turning action. It is like shoes - comfort at some pricepoint. smoothness of action - you can oil up most Craftools and make them fairly smooth. The higher end ones are smoother because of bearings. On some you can tap the yoke and they'll spin a long time. You aren't ever going to turn one that fast in use, but it attests to a more quality and detailed construction. Sharpening - there are a very few people on the planet who can free hand sharpen a swivel knife blade to the best it can be. The rest of us really need a jig. The roller Craftool one works. Chuck Smith makes one, Gordon Andrus makes one, probably others. I've got one I made for my variable speed knife sharpener. Point is - use something for a flat edge. I go to 5000 grit before I think about stropping - that's just me now. I wish I did when I was carving a bunch, I'd have fought my knife a lot less. Strops are cheap - piece of manila folder with your favorite flavor of compound. The softer the steel the more often the blade will need attention. Overstropping softer blades with an aggressive compound will round them unless you are really gifted. Better off to run them on a jig with fine grit a bit and then a few strokes stropping than strop one a hundred strokes. How do you pick a knife now?? You need to figure the configuration that is comfortable to use and in your budget. They are again like buying shoes - fit matters. try them if you can first - somebody's shop or a show. Budget will tell you which makers to look at.

-

The only Paasche knives I know of are stencil cutting knives, not leather swivel knives.

-

ISO Hamley Daisy/ Prairie Rose Stamp for Sale/ Rent

bruce johnson replied to cwcustoms's topic in Old/Sold

Where are you located, how long would you need one, and when would you need one? -

I like open ended edgers like old Gomphs, old Osbornes, modern like Ron's Tools, Barry King, Horse Shoe Brand Tools round edgers, and some other makers I going to forget but not intentionally. I got a set of WUTA or similar in a set of tools. they sharpened up well and my wife likes them for her thin leather projects. Pretty small. Palosanto tools are good but can be really brittle and require care in use (especially their French edgers). With all of these you can strop the top and bottom of the cutting edge. The Craftool edgers you show are harder to do that. You can sharpen the bottom and the bur edge rolls up and hard to get in there and see what's happening. Plus those edges can be really steep angled and chisel more than slice. My 2 cents worth. Sharpening? For hand sharpening you are on the right track with the rods and paper. I'd only say that 400 grit is where I start, not finish. Work until I get bur and then I progress through 5 or 6 grits up to 1500 and more often than not 2000 if I am doing one by hand. Then I go to the strop top and bottom. With some some profiled edges I buff the top. Stropping out 400 grit marks is tedious and most people quit too soon. Go to 2000 on paper and then 20 or so strokes on the strop should have it. I still do some by hand but I also have variable speed grinders and buffers with profiled wheels that make life easier and more repeatable edges.

-

When you are looking realize that size numbers mean very little from one maker to the next. The older system for the Osbornes and Gomph was each number on edgers was 1/16” of cut. The newer ones (within the last 40 years) don’t correlate with other makers size numbers.

-

Totally agree with Bob. Limited in what they can do, marks up the back side. I bought one from Ron (Ferdco in Idaho) when the 440s were advertised in horse and tack magazines for $1500. Anything else new that stitched leather was $5000 or more at that time. I had it a day and realized that the mechanics of it was not the machine for me. Ron offered me a used Adler 205-64 head as a replacement and we swapped heads for "$1000 - I'll hold the check and you tell me when to cash it". Best deal I could have done, they really helped me out when I needed it! The Adler was bullet proof and made me a lot of money. Not a fan of the 440 for good stuff. I know people who sew production belting stuff and replacement tack parts on them, but finer stuff was just not passable for me.

-

I checked and sorry but don't have either for sale or coming up for sale, just the 6 petal in a few sizes in my personal set. You could expect to pay $75-100 for them when they come up. I sold a few of the six petals at the Sheridan show for $90. These good old McMillens don't come up like they used to. The 6 petal stamp is a little more common than the dots stamp. They haven't made any stamps for several years with no plans to start stamps again.

-

Butt leather is the firmest part of the hide to start with. Belting leather may also have been compressed to remove some stretch. There is not as much flex to that butt part of the hide because it is tighter. It is an advantage for some things and disadvantage for others. Making a sharp bend or fold in it can sure split the grain. Best leather and any leather that has been compressed (aka "jacked") is more prone to cracking when folded there. The firmer flesh part will not compress as easily as lower side, shoulder, or neck sections when folding. When you fold it this makes more tension on the grain portion of the thickness and can lead to the cross splitting. One trick is to soften that area with warm water prior to folding to somewhat case it.

-

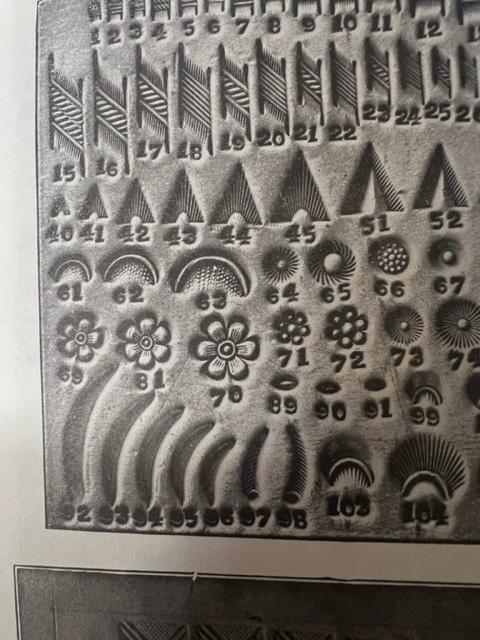

Top one could be a McMillen, especially if the holster is old. I’ve probably got it. Bottom is mcMillen. Like in 81 or 70 and 72in the old McMillen catalog

-

I have had zero problems with anything in these tubes - chrome tan, veg tan, or oiltan. Some of the chrome tan leather we pick up on specials at shows sits for a few years before it is used up now with no problems. These tubes are durable and most are still the originals from at least 17 or 18 years ago. She has replaced a few bigger tubes with more smaller ones now since she uses more chrome tan than I did.

-

Grain Or Flesh, Which Is Stronger?

bruce johnson replied to TomE's topic in Leatherwork Conversation

Yes I think the grain side generally has more tensile strength. If it didn't we would be using splits to make good lace. That said, some tannages of splits carry some good strength like pearl apron splits for aprons and horn wraps. My opinion on grooving is just this - my opinion. I am a groover, I have stickers on my sewing machines to remind people who use them to groove. First and foremost it gives you a visual target to stitch in. Edge guides on machines are nice but not foolproof. You can have the nicest machine - dialed in with the prefect thread and needle combination and tensions just right. Make one wiggle in the line and it is like a zit on the prom queen's nose. You see it first and last. People who say grooving weakens the leather - here's your test. Groove off a section and pick up that little leather thread that you just grooved off. Pinch it between your fingers on each hand and pull. Pretty flimsy and about zero tensile strength. It is not taking away anything from the strength of your leather and likewise leaving isn't adding anything. Edger trimmings have more strength and we edge our leather religiously. -

Here's how I did it 15 years ago and my wife does now. The 4 foot long Gorilla racks hold the Sonotubes perfectly. Chap and latigo are sorted by color and type so they don't bleed on each other. lighter weight Vegtan same thing. I was pretty busy then and I went through 5 side or 10 side skirting sides fast enough they never marked from light exposure. They were just rolled loosely and secured with a bungee. One of these 6 foot high shelving units can hold a lot of rolled leather with easy access. Ignore the open wiring in the background. This was during a shop upgrade and the electrician was replacing the DIY job the previous owners had done.

-

The brass handled ones are beautiful. Until the later 1800s they were all brass and wood handles. I've got one going back to the 1830s very similar except no trigger. The triggers were a late 1860s addition. I've got a couple showpiece kind of plough gauges that were my daily users also. I like pretty tools.

-

There are a lot of ways to cut straps but not many are stronger or prettier than these 100+ year old draw gauges. These are among my favorite tools to refurbish for sure. Somewhere along the line we changed from function and beauty to ease of manufacture and price point on a lot of tools. I'd bet the old guys that owned these oldies first were pretty proud when they got them and I always hope I've honored them.

-

Welcome back Shirley!! Some of us originals are still around

-

As mentioned tannage can play a part and everyone wants to blame tanners in 3rd world countries that use urea or urine. Maybe some still do but some of the chemicals and bark sources are similar and can give that odor. If it is truly cat pee and pretty well permeated into the leather, you can spend time and materials to clean it with maybe so-so results. You can consider the time involved and toss it to use something fresh that you and ultimately customers wont find offensive. 10-40 year leather is harder to work generally unless it has been stored really well. Smelling like cat pee tells me it hasn't. I've been to shops where the shop cat(s) are not the most litter box trained beast. Eventually everything catches that odor - tools, boxes, packing material besides leather. I have had packages from one place intercepted and inspected because they smelled of urine and drug inspection dogs hit on them - just like smuggling drugs and trying to mask it with coffee.