-

Posts

5,797 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Constabulary

-

Bobbins to fit pearson #6 shuttle

Constabulary replied to T Moore Medicine Hat Saddlery's topic in Leather Sewing Machines

I have heard the Aaron Martin bobbins only fit their new shuttles but not the original shuttles... -

Prettiest singer 111w155... biggest pain in my butt

Constabulary replied to BrownChicken's topic in Leather Sewing Machines

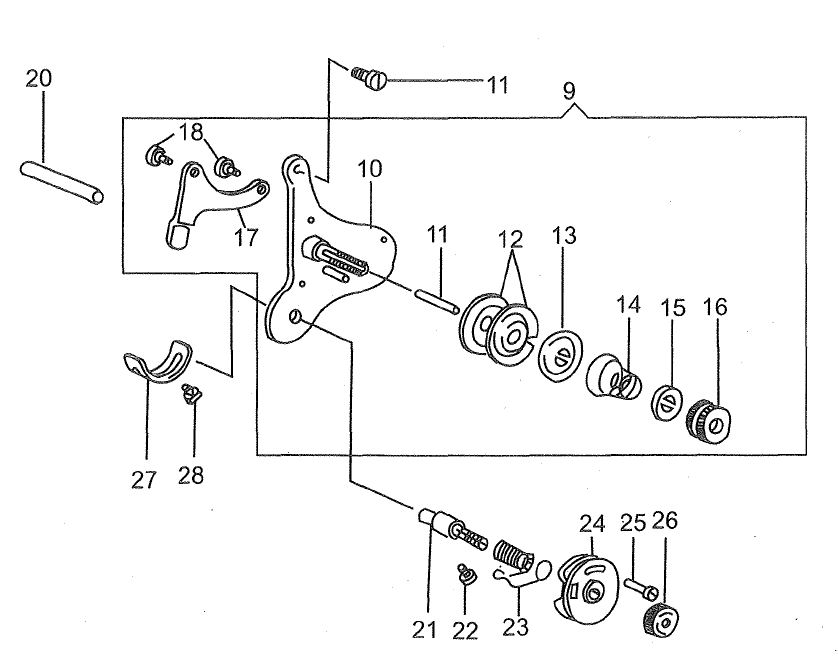

How can you break a complete tension unit? Are you sure they are broke? 1st I´d remove the tension unit again and check if the pin that goes from front to back through the machine head is present - if not you need a new pin (obviously). #20 in below picture The procedure you have linked above works for your 111 as well but before you rip apart everything check if that parts is present and if it is broke or not. It is covered with a large head screw on the back side. If pin #20 is present and the tension release on the backside is present and functional you can try to bend #17 a little bit to war the pin #20 or a adjust little center bar on the tension release disc #13 by tapping it a tiny bit towards the pin #11. Or buy bicycle spoke and cut a piece a bit longer than pin #11 and replace it - all that is trial and error.- 24 replies

-

- tension release guide

- singer 111

-

(and 1 more)

Tagged with:

-

remove the V- belt and try to hand crank the machine so you can narrow down if the problem is the machine or the motor. Maybe machine is gummed with old oil or thread accumulated in the hook era. If gummed "oil it" with kerosene so the gummed spot can break loose. I have attached some Class 18 manuals, maybe they help a bit. 18-22_23_25_26_27_35_36_37.pdf 18-2.pdf

-

Singer 45K89 w. Reverse on Ebay UK

Constabulary replied to Constabulary's topic in Leather Sewing Machines

ha ha - you learn something new everyday - never noticed this before - holy crap Thanks for the hint, Neil! -

Singer 45K89 w. Reverse on Ebay UK

Constabulary replied to Constabulary's topic in Leather Sewing Machines

That one looks modified to me - the jump footy system looks like one from an Adler 4 (I guess) and seems the adjuster screw for the jump foot system has been replaced with an odd one - it also has no reverse and seems to be "cheaply" over painted (did not remove parts in advance) I would not buy it without having it tested. The more I look at it the more I would not buy it at all. EDIT: Yeah - just noticed the seller name - seems to be wear some "brownshirts" - (where is the puke smiley) -

Singer 45K89 w. Reverse on Ebay UK

Constabulary replied to Constabulary's topic in Leather Sewing Machines

will check for the plate - I know I have a right side plate... will send you a message later -

http://www.ebay.co.uk/itm/Singer-45K89-Leather-Sewing-Machine-With-Motor-Lamp-And-Desk-/252912248287?hash=item3ae2bea5df:g:LHgAAOSwX61ZB1jB Not mine but maybe a good deal fro someone on the island.

-

29K51 I would guess. It already has the helical spring instead of the blade spring on the backside. A lot of 29K71 parts will fit. The gear box you can drop out to the bottom when the shuttle carrier is in the right position (if not rusted or gummed). Problem on the 50´s subclass is that it has fine teeth pinions in the gear box and they are not available as replacement when worn off or broke. Thats the only negative other than that its as good or bad as any other 29K. If you cannot turn the hand wheel do not put too much force on it because you could break the fine teethed pinions if a broke needle tip found its way into the gear box or the gear box is heavily gummed or rusted (you never know). The bent parts on top of the head are an easy fix - 29K71 parts will fit.

-

scrap in quotation marks - leftovers is probably the more correct word You are right - they don`t ship the controllers to the US But I´m sure you will find similar controllers on ebay.com too. EDIT: There you go: http://www.ebay.com/itm/AC-110-220V-2000W-SCR-Voltage-Regulator-Dimmer-Speed-Temperature-Controller-FT-/282184459457

-

bobbins Twisting Thread Winding Bobbins

Constabulary replied to tmitch's topic in Leather Sewing Machines

You have to post pictures - no one can imagine how your set up looks likes. So when the mess is happening on the thread spool I would try a boot sock netting and / or give more tension on the on the bobbin winder pre tension unit or has your machine a built in bobbin winder w/o pre tension? Sorry but we only can guess with out seeing pictures. -

Something Different....a Singer 172K

Constabulary replied to alexitbe's topic in Leather Sewing Machines

Ha ha - for suuuure! But I´m kind enough and would leave one for Wiz Wiz, maybe we can convince Eric that we will "dispose" them properly. -

So here are my 2 versions of an DIY electric bobbin winder. One is for 111 type bobbins and the other one for 45K (and similar) barrel type bobbins. Being honest at the first I was not convinced that I would need these stand alone bobbin winders at all - due to the table / machine mounted v-belt driven winders I have. But after I thought I could make one from "scrap" parts I have floating around + some "china bits" I had to order I gave it a try... Well, meanwhile I don´t use the other winders anymore... After I was done with the 1st winder I was thinking of adding a micro switch to shut down the motor when the bobbin is full but then decided its not really necessary (would still be a nice featured but... well, maybe later) and the plain switch is working fine. Instead of a foot pedal I have installed a speed controller "on board" so I can pre dial the most comfortable speed (motors have 4000rpm ). The controllers and plastic housing can be found dirt cheap on Ebay. Housing: http://www.ebay.de/itm/152131518287 110 V / 220V Controller: http://www.ebay.de/itm/391609751588 111 winder:

-

Something Different....a Singer 172K

Constabulary replied to alexitbe's topic in Leather Sewing Machines

If you have no use - I take em and will dispose then environment friendly -

Singer 111w101 questions

Constabulary replied to melancholycoyote's topic in Leather Sewing Machines

old cloth timing belts may last longer than expected - I have a Singer 111WD (Made in Germany from before 1945 - a barn find + used as garden decoration) and its still has its cloth timing belt in good working condition where as the machine externally is poor. Your machine has the old stitch length adjuster on the end of top the drive shaft near the hand wheel. Thats for sure not state of the art but it works but the machine also has no reverse. Unless you like vintage machines and like tinkering I would not buy even it if is cost more than maybe 150 - 200. But I really like the nice big table - that could be worth $100 or more alone. The mentioned Juki and Consew are for sure the easier to work with machines. However I personally would buy the machine if it is real cheap since I like old machines and tinkering very much but thats not everybody´s cup of tea. If I were in your position I would choose the Juki LU-563 -

I think they are as good as other machines but I have my very own opinion. They may be more effective in use but I think on the long view direct drive machines are more expensive than machines with separate motor. Reason why I think this is you have to turn in the entire machine when (one day) the motor is broke. When you have a separate motor you just buy a new motor install it and you can use the machine within a few hours or maybe a few days (when buying online). And most likely these directs drive motors are not "universal" (like most separate motors). So most machines / machine brands (probably) have their own "dedicated" motor (I think) and and there will be a day when a company no longer supplies spare parts (or motors) for their "older" machines. There may be after market motors but finding them and adapt them for your machine could cost some $$$ and time. An on top of that we all know (or have heard) of planned obsolescence... at least something one should think about before buying a direct drive machine (or other electronic controlled devices). Don´t get me wrong - I do not say direct drive is bad - not at all - my opinion just is that on the long view separate motors are more economic. Just my 2 cents - others may have a different opinion but I (personally) would not buy a direct drive machine. It of course depends on your output and if you can write off / depreciate a machine like this. But I think most of the small business folks will keep their machines for years (or even decades) and cost efficacy for sure is something you have to consider - especially as a small business. and now throw the pooh to me...

-

bobbins Twisting Thread Winding Bobbins

Constabulary replied to tmitch's topic in Leather Sewing Machines

What bobbins are you winding? Standard bobbins (like Singer 111) or barrel type bobbins (like Singer 445K or 441 type machines? You probably have to adjust the position of the tension unit on the winder or maybe in crease the tension.Could be poor thread too. Post some pictures please. -

29K1 Pre Christmas Barn Find :-)

Constabulary replied to Constabulary's topic in Leather Sewing Machines

BTW - since you are in Sweden I´d check with College Sewing in the UK, thats where I bought my 29K parts: https://www.college-sewing.co.uk/store/82167-FEED-MOTION-BELL-CRANK-LEVER-SINGER-29K And this is their 29K parts list - but not all of them fit for any 29K model... https://www.college-sewing.co.uk/store/Singer29K,29USewingMachineParts -

29K1 Pre Christmas Barn Find :-)

Constabulary replied to Constabulary's topic in Leather Sewing Machines

With my 29K71 I´m very very close to 5SPI but when I make 20 stitches (21 holes) and measure I´m a bit below 5SPI. I´m very very please with this result! Investing in a new feed motion BCL is worth every cent. @ Oldtimer - when you buy a new BCL you nowadays find them for "more modern" 29K71 /29K73 and the like and they will fit your earlier 29K (29K1, 29K3, 29K4, 29K33 and so forth) model too when you modify them a little bit. I had to grind down some spots but that was no big deal. Do not buy used BCL only because some one sells it for exactly your machine model since they are (most likely) a bit worn already. When the BCL is new the round tip has approx 5mm in diameter -

29K1 Pre Christmas Barn Find :-)

Constabulary replied to Constabulary's topic in Leather Sewing Machines

yes, the bell crank lever has a huge influence on the stitch length but the feed motion ring as well when it is worn (thats the other part you see in 1st and 2nd picture) -

Singer 45K Treadle Base Parts Information or Parts List

Constabulary replied to Evo160K's topic in Leather Sewing Machines

Yeah but I heard that sewing machine folks are totally nuts -

Singer 45K Treadle Base Parts Information or Parts List

Constabulary replied to Evo160K's topic in Leather Sewing Machines

HOW FREAKIN COOL IS THAT? I was not even thinking of that as a DIY. Maybe an idea for making "blue guns" for holsters out of aluminum or brass (cartridge shells?) Male weekend: drink dozens of beer - make fire - melt beer cans - use foundry for grilling some sausages - drink more beer - melt more beer cans - cast blue guns What else do we need, Beer, barbecue, fire, guns -

Singer 45K Treadle Base Parts Information or Parts List

Constabulary replied to Evo160K's topic in Leather Sewing Machines

or maybe "someone" can make a mold of alginat (or the like) and then make a silicone or rubber reproduction and can send to you EVO so that you can let it sand cast (if possible and affordable) - maybe just a stupid idea....