-

Posts

5,801 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Can anyone identify this machine?

Constabulary replied to bikermutt07's topic in Leather Sewing Machines

I´d think twice if you really want this machine for leather work. It´s for sure great for very heavy canvas and webbing work. Look at it, test sew it and then decide. -

Looking for a shoe patch machine

Constabulary replied to T Moore Medicine Hat Saddlery's topic in Leather Sewing Machines

Sounds like a good deal. If it really is a 30-5 then it is a small (standard) bobbin machine but it is using 332 L (LONG) needles instead of the standard 332 / 29x1 needles. These needles 332 L are 10mm longer than 332 needles. Just wanted to have it mentioned. You can find a manual for this machine here: Adler Class 30 Manual To get in touch with the seller click the gray REPLY button top left side above the picture. -

Anyone wanting to add a Singer 97*?

Constabulary replied to SARK9's topic in Leather Sewing Machines

......... ......... -

I think ideal is a flat bed machine with wheel feed (dog) and roller foot. If the 345 is very cheap I´d buy it anyway! How much is it? When you make sharp turn while sewing the stitches become longer / shorter. There are some interesting Videos from Lisa Sorrell (Boot maker) showing her technique - check her other videos too.

-

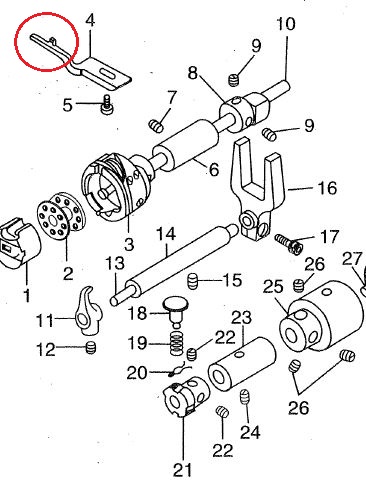

Should be mentioned in the Consew 206 manual Page 14. 206RB-5 Instruction Manual - Consew 206RB-5 Parts Book - Consew The hook supporting plate (#4 see attached parts list page 14) has a small finger which holds the inner parts of the hook in place so the outer part can rotate. The small finger 0n #4 has to sit inside the notch (see pictures)

-

few machines to choose from, which one would you pick

Constabulary replied to beltbuckles's topic in Leather Sewing Machines

and the adjustment manual: Adjustment Manual-Pfaff-138.pdf -

few machines to choose from, which one would you pick

Constabulary replied to beltbuckles's topic in Leather Sewing Machines

I have attached a list of sub classes and parts list Pfaff 138 Unterklassen.pdf Pfaff 138 Teileliste.pdf -

few machines to choose from, which one would you pick

Constabulary replied to beltbuckles's topic in Leather Sewing Machines

I´d take the 138 too. I once owned one - very smooth running machine when properly set up (as most other sewing machines too). It is more or less the forerunner of the 438. I´m not sure if it has a build it oil pup or if it is wick oiled (from a reservoir) most built in oil pumps work at high sewing speed only. Also the 438 has a timing belt which sooner or later needs to be replaced (maybe tomorrow - maybe in 5 years) and replacing these belts often is a pain ITA or cost some good money. The 138 has a drive shaft instead (is it called drive shaft?) which needs no replacement. The only known problem of the 138 is probably that the zigzag adjuster could be gummed but thats something you can solve with heat and oil w/o bigger problem. When your zig zag adjuster is not gummed - even better. The 138 is well documented as well you find everything from manual to parts list and service instructions online. Though I have not checked for the 438. However - If I had to choose I´d take the 138. -

Odd Adler Cylinder Arm Machine?

Constabulary replied to Chuckydownunder's topic in Leather Sewing Machines

Interesting combination with a patcher treadle base... not easy to work with in this combination I think. -

Odd Adler Cylinder Arm Machine?

Constabulary replied to Chuckydownunder's topic in Leather Sewing Machines

feed up the arm + zig zag I guess - stitch length adjuster seems to be right of then front wheel - though not sure, I think I never have seen one of these before. -

Singer Leather Sewing Machines

Constabulary replied to Trevor Baret's topic in Leather Sewing Machines

2nd what Bob said - they will never ever fit! The K50´s sub class gearbox has a total different design.- 53 replies

-

Odd Adler Cylinder Arm Machine?

Constabulary replied to Chuckydownunder's topic in Leather Sewing Machines

The side wheel is for comfort because you cannot reach the and wheel. Seems to be a zig zag machine the lever that slides behind the what makes me think this... Don´t know the Class of this machine. -

me too...

-

Thats the Galaxy 8 of sewing machine stands - very cool - question is do I need it or do I just want it because its cool and do I have the necessary amount of pennies... Personally - I would prefer a crank model! Uwe, if you have seen more "space machines" please post em - always nice to see these inventions. So when you are back home there will be an UWE version of this stand soon - right?

-

Are you offending me, Tor? Jimi from Spain is Singer crazy too... I´m sure there is a dark figure of "secret Singer users" in Europe - like the free masons

-

that always looks good - thats my preferred combination too but the closer it looks to the original the higher the possible resale value is. Odd looking machines is something I would not buy. Avoid over painted screws and parts. This is something that tells you (or a buyer) the restorer did not care very much...

-

Prettiest singer 111w155... biggest pain in my butt

Constabulary replied to BrownChicken's topic in Leather Sewing Machines

Will scan the manual sooner or later but I have not the patience at the moment - sorry. Maybe this thread gives you some helpful hints:- 24 replies

-

- tension release guide

- singer 111

-

(and 1 more)

Tagged with:

-

Prettiest singer 111w155... biggest pain in my butt

Constabulary replied to BrownChicken's topic in Leather Sewing Machines

they are mine - I invested some $$$ and bought original manuals for my machine (approx $25 incl shipping to Germany) Nothing beats original manuals. You will notice the difference when you look at the screws D has a very coarse thread- 24 replies

-

- tension release guide

- singer 111

-

(and 1 more)

Tagged with:

-

Prettiest singer 111w155... biggest pain in my butt

Constabulary replied to BrownChicken's topic in Leather Sewing Machines

Do you have a manual for this machine? The procedure of adjusting the foot lift while walking is mentioned in it - easy task if the mechanism is not gummed.- 24 replies

-

- tension release guide

- singer 111

-

(and 1 more)

Tagged with:

-

Best machine for sewing 20-24 ounce

Constabulary replied to T Moore Medicine Hat Saddlery's topic in Leather Sewing Machines

what leather products have a thickness of 1" - just wondering - I have no idea.... -

that´s why they are special

-

a bit a different accessories put the machine in a different sub class sometimes - like Singer 29K - just an added wax pot puts it in a different sub class. Same with 45K´s I´d say - the machines may be technically the same but the accessories that originally came with the machine are different. Parts list are an interesting read sometimes...

-

you know that this is a domestic garment sewing machine, right? Addiction comes with the time especially when you start restoring old clunkers and they turn out nice and work fine when done... Trust me I know what I´m talking about

-

Bobbins to fit pearson #6 shuttle

Constabulary replied to T Moore Medicine Hat Saddlery's topic in Leather Sewing Machines

how much shorter are they (or too long)? If too short is there probably the spring loaded piece missing that is holding the bobbin in place? Always good to see some pictures. Regarding your stitch length adjuster I´d also post some good detailed pictures of your machine in the other thread - maybe someone else can see what is wrong. Pictures tell more than 1000 words.