-

Posts

5,805 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Looks like a Singer 236 will wheel feed. They usually have a very short stitch length. I don´t think its a clone I still can see the Singer badge.

-

Roller Foot for Adler 205-64?

Constabulary replied to Cumberland Highpower's topic in Leather Sewing Machines

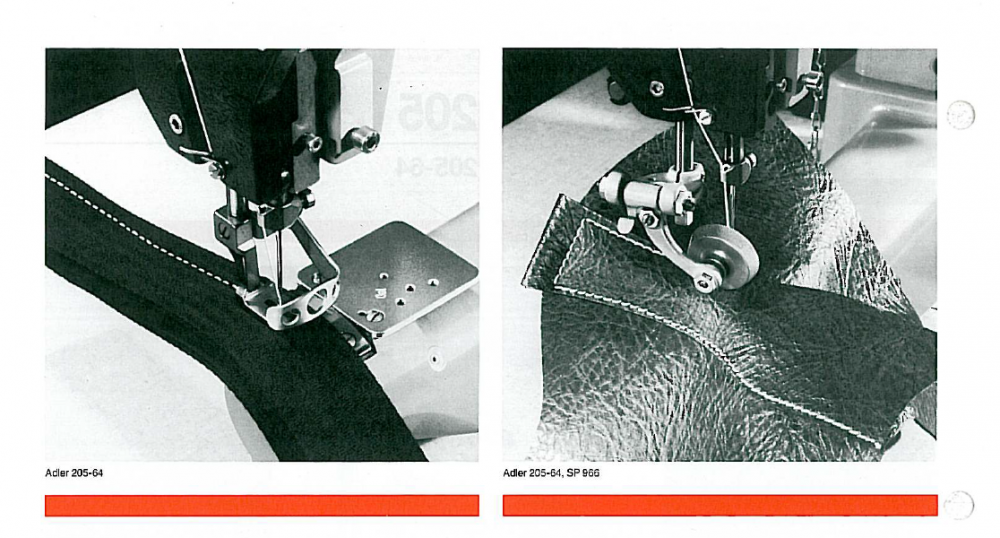

The Adler roller feet (Class 4, 5, 104, 105, 204, 205) are all the same none of them were attached to the regular squared foot mount. They all slide onto the foot bar and have a round mount with clamping screw. These roller feet are a lot beefier than the "plain" roller feet you find for Singer 31K and the like!!!! I would try MJ Foley or Weaver Leather, maybe they can supply the ADLER roller foot. EDIT: See picture -

Roller Foot for Adler 205-64?

Constabulary replied to Cumberland Highpower's topic in Leather Sewing Machines

They are very hard to find but just in case the Singer 45K Adler 4 / Adler 5 roller feet are the same. Not sure who offers the clones but they were available at one time: https://www.ebay.ie/itm/Leather-Roller-Foot-For-Singer-45k-45k25-45k21-GA5-GA5-1-P-No-82435-91675-/221448164280 -

Have you checked if your forward and reverse stitch length are the same? Or is reverse probably longer than forward? If they do not match the adjustment procedures is mentioned in the manual. Usually when you increase forward stitch length the reverse becomes shorter and the other way around.

-

Having problems binding around corners

Constabulary replied to chrisash's topic in Leather Sewing Machines

College Sewing - they have tons of different binders, folders... Not sure if they still offer the printed catalogue but it is worth having. Great reference for binder attachments and so forth. https://www.college-sewing.co.uk/folders-attachments -

if you have them as PDF please share them here.

-

Singer 45K89 missing tension parts or not?

Constabulary replied to Oldiesfan's topic in Leather Sewing Machines

Nice!!! Too bad the parts for the jump foot are missing. I love the cast iron stand very much! -

Best patch sewing machine for arms and pockets

Constabulary replied to BikerNettie's topic in Leatherwork Conversation

IMO the best but for sure the most expensive is a CLAES 8346-30 or the predecessor 8345-30 or 200-30. the #30 sub class is one with the largest hook & bobbin and highest foot lift, there re also #10 and #20 sub classes but they have smaller hooks. Downside is that the parts are super expensive but they are technically the most advanced patchers and have the longest stitch length of all patcher machines. Followed by the Singer 29K70, 29K71, 29K72 and 29K73 they have the best parts situation because they are still mace by Chinese companies so the parts are fairly cheap. The 29K72 has a larger hook & bobbin compared with the other mentioned models. So on the long run you can run the mentioned 29K models most economically. There are a lot more 29K models but the lower the sub class number the older the machines and the worse is the parts situation. For older 29K´s you still can buy certain parts but critical wear parts like gear box pinions are almost unavailable or in best case hard to find. -

Or DIY a simple cyclone dust collector. https://www.youtube.com/watch?v=1WnitgYFnE0

-

holy smokes - thats really nice !!! This is how my cat would look like, I think I´m close, right Wanna see my dogs too **kidding**

-

I designed these shoes is anyone interested

Constabulary replied to Jojomojo's topic in Shoes, Boots, Sandals and Moccassins

When some one puts a link to a sale site and asks for "interested" it to me looks like he wants to sell something / boost sales / wants to promote his shoes (what ever). To me it does not look as if he was asking for opinions on his shoe design or workmanship. Even if I liked the shoes design wise - I would not buy them because of the super low profile cheapish looking soles that probably wears off in a few weeks (or days?). Thats not sustainable, just another throw away fashion piece. We have far too much of this fast fashion junk. Every Chuck Tailor All Star has a better sole. For me the soles on shoes are very important. I´d ask the shoe maker for better soles but looks like this is a kind of kit and you have no other options. Since the shoes are made in Italy check with VIBRAM they make All Star soles as well. My opinion. -

What kind of Singer Machine did I buy ?

Constabulary replied to Oldiesfan's topic in Leather Sewing Machines

I have one - please send me a PM with your email address If the hook is missing the machine is using the large 29K hooks as for the singer 29K60, 29K72 or Adler 30-7 -

Singer Patcher 29k53 - not picking up bobbin thread

Constabulary replied to LomaeArts's topic in Leather Sewing Machines

6 seconds is not much to figure an issue Do you have a manual? To me it looks like you have to advance the shuttle driver. -

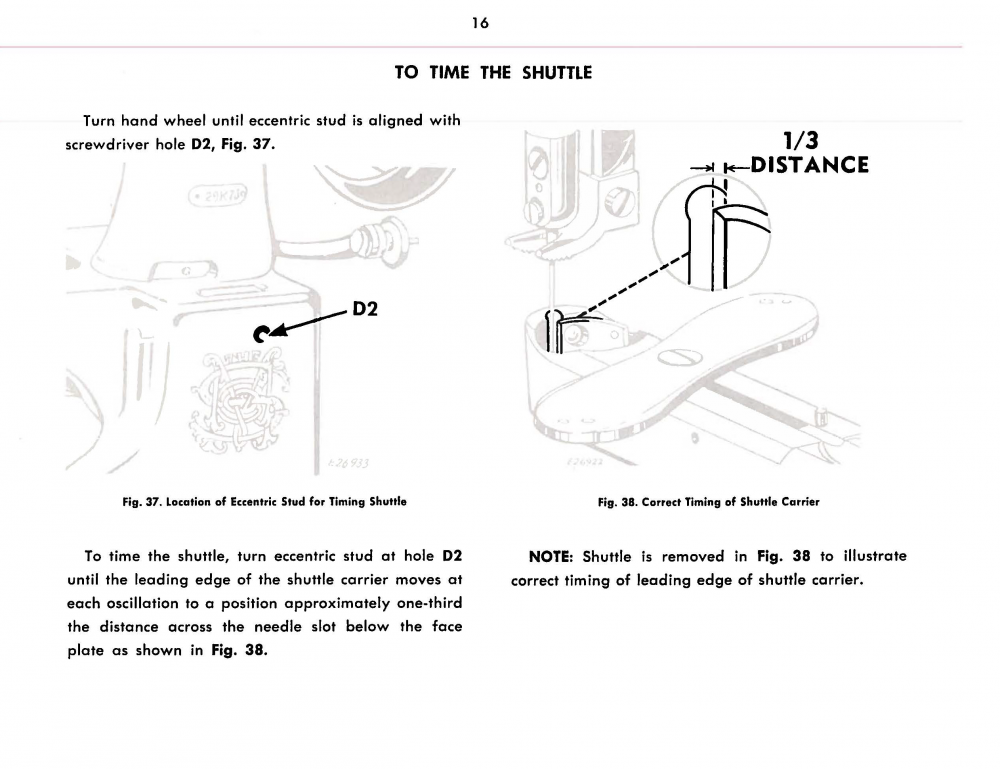

You don´t have to grind down needles. You can simply adjust the height of the needle bar. But different needle system can have slightly different length needle tips. I have a 108w20 which basically is the cylinder arm version of the 151w and the hook is the same. Longer needle tips are sometimes scratching on the hook body. My 108w20 is a bit picky with needle tips. I have attached the manual. For adjusting the NB height see page 18. Test the needle by hand cranking the machine and listen if the needle is scratching on the hook. 151W1,W2,W3-Inst.pdf

-

I designed these shoes is anyone interested

Constabulary replied to Jojomojo's topic in Shoes, Boots, Sandals and Moccassins

Do you allow critical questions? To me it looks like a scam website to be honest. -

I tried to explain it in this post already https://leatherworker.net/forum/topic/96713-looking-for-singer-111g-right-slide-plate/?tab=comments#comment-656977

-

Nice! Please post some more pictures of this machine so we have a reference for other members. Seems to be a Singer 16 needle so I would look for needle system 1738 which is also called 16x23 or 16x257 or DBx1 or 287 WH sometimes. Or depending on the needle holder and / or the size of the hole in the needle bar you probably can use a more common needle like 134R or 135x17 but you have to adjust the needle bar height. The 2 mentioned have a ~2mm shank diameter whereas the original system has smaller diameter. If it was my machine I would order a pack of lets say size 120 needle in 134R and just test if they fit. Adjusting the needle bar height is an easy task.

-

Singer Patcher 29k53 - not picking up bobbin thread

Constabulary replied to LomaeArts's topic in Leather Sewing Machines

have you tried to move needle holder a bit closer to the hook? Needle holder may be tight in its position but generally you can move it a bit sideways. -

Believe it or nor when I was tinkering on my Singer 51w I had a similar problem. I installed a Durkopp brand hook cause the OEM Singer hook was badly worn. The top thread kept hanging and I could not figure why. I tried different brand hooks, even ground down the hook body, tried different brand bobbin cases and nothing worked until I figured the "rail" on an OEM Singer 111 bobbin case is a bit shorter and so I replace the Durkopp bobbin case with the OEM Singer bobbin case and it worked! So the thread kept hanging on the slightly longer "bobbin case rail" when the top thread has been pulled up I have used not the OEM throat plate and not OEM hook so this "special parts situation" can probably not copied to other sewing machines but I just want to give a hint. I cannot put the parts in a good angle to show the difference but the rail on the left bobbin case is approx 1mm longer. Picture shows a sample but the rail on the OEM Singer bobbin case # 233764 (at least on my bobbin case) is even shorter (2mm I think - compared with the Durkopp bobbin case) and that shorter rail solved the thread handing problem - at least in my special case. maybe this helps - maybe not.

-

Looking for Singer 111G right slide plate

Constabulary replied to chrisash's topic in Leather Sewing Machines

usually there is a slot in the plate and you can bend the "thorn" a little bit with a screw driver for adjusting the fit. Thats not unusual, Pfaff Adler and other brands have similar side plates. -

appears to be the needle feed version of the Juki 341 - it at least appears to be quite similar

-

@Tacha You have a PM

-

Stitch Length Regulator on Consew 226r-1

Constabulary replied to BelleH's topic in Leather Sewing Machines

this is what I had in mind when thinking of the 226 seems there were casting variants: -

Stitch Length Regulator on Consew 226r-1

Constabulary replied to BelleH's topic in Leather Sewing Machines

oh - right - I see - sorry! I thought the Singer 111 clones would have this window too... I have edited my last post (see above). So maybe then it is the position of the hand wheel on the top shaft. Usually the hand wheel is held by 2 set screws in a certain position and one set screw sits in a grove on the top shaft so maybe the hand wheel is positioned incorrectly. You know what I mean? -

Stitch Length Regulator on Consew 226r-1

Constabulary replied to BelleH's topic in Leather Sewing Machines

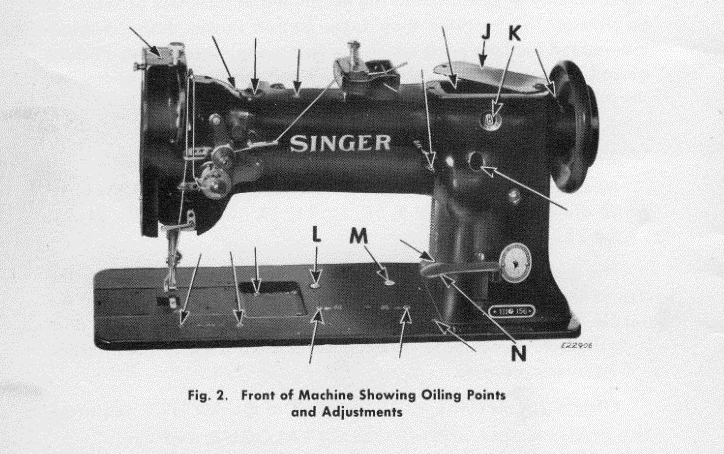

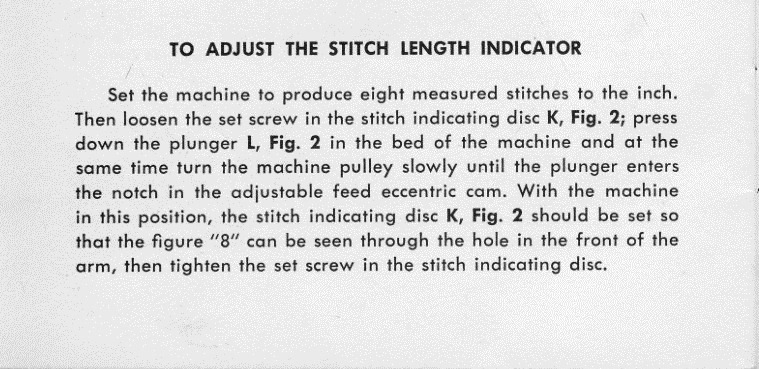

The stitch length dial is held on the top shaft by a set screws. Dial in the longest stitch length (5SPI) open the top cover then loosen this set screw and rotate the dial until you see the "5" in the window then tighten the screw again. This does not change any settings on the machine or so it is just the position of the dial you alter to match the dial with the stitch length. But as you can imagine the dial is not necessarily 100% precise cause the window gives quite some room for displaying the number on the stitch length dial. Just play with it a little bit with the dial position. I think Singer says in the 111 manual you should do this with 8 SPI. Let me check the manual... EDIT: Yeah, 8SPI - this most likely is because you can reach the set screw in this position. This is from the Singer 111 manual: