-

Posts

5,759 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Constabulary

-

Need help with Singer 211U566A

Constabulary replied to Parfektionisto's topic in Leather Sewing Machines

if you can´t hold down the spring and tighten the set screws at once ask someone for a helping hand or DIY a tool - f.i. a tube with a cutout lengthwise. Length: measure from end of the flange sleeve the to shaft bushing on the right. Just an idea. -

How thick are the 2 layers in total? The total material thickness makes a big difference especially when using thicker thread and larger needles. Its easier to balance the thread knot in thicker materials when using thicker thread and larger needles. If not pleased with the thread knots visibility try a thinner thread and smaller size needles. Or when the bottom seem is not visible on the your product lower the top tension or increase the bottom tension a bit and the knot will move a bit to the bottom side. Or use a 1 size thinner bottom thread.

-

Need help with Singer 211U566A

Constabulary replied to Parfektionisto's topic in Leather Sewing Machines

I´d almost say the problem sits in front of the machine *kidding* The grove for the plunger looks not worn and thew plunger looks long enough. So I only can guess that you don´t push it down deep enough or do not hold it down tight enough or the cam is badly gummed with old oil but then the plunger should still engage. Try this - when you push the plunger and SLOWLY rotate the hand wheel and when you come to the point where the plunger should engage and you feel it goes over the grove (you feel it and hear it) slowly turn back the hand wheel and jiggle it back and forth a bit until the plunger engages. If you cannot hold down the plunger in the deep position put a screw nut (or the like) between finger and push it in deeper. I have two machines with this stitch length adjuster (111G, 212G) and on the 212 it kinda feels more "fiddly" (thought is the same system) and on the 111 it works better but still both work well. was just a guess w/o knowing what is going on on your machine and before I saw the videos. -

Setting my Pfaff 1245 to work leather

Constabulary replied to jadub's topic in Leather Sewing Machines

now its obvious maybe check with Keystone sewing in PA or Toledo Sewing in OH -

Setting my Pfaff 1245 to work leather

Constabulary replied to jadub's topic in Leather Sewing Machines

So you think it will not sew leather? Why? Do you have some pictures? -

Need help with Singer 211U566A

Constabulary replied to Parfektionisto's topic in Leather Sewing Machines

Set screws on hand wheel loose? Maybe? -

Need help with Singer 211U566A

Constabulary replied to Parfektionisto's topic in Leather Sewing Machines

when the safety clutch is disengaged the hook no longer spins. Yes with plunger (Singer term) I mean the button in the flat bed. What means it moves back? You have to hold down the button all the time until the wanted stitch length is adjusted or do I get you wrong? The button is spring loaded and does not stay put by just pushing it once - you have to hold it down. -

Have you checked the bobbin case opener? Is it working properly or is the thread probably handing there? Or do you have a tension release while sewing maybe because foot rests on foot lift pedal or knee is touching knee lift lever? Just guessing.

-

Need help with Singer 211U566A

Constabulary replied to Parfektionisto's topic in Leather Sewing Machines

Are you sure you haven't disengaged the safety clutch - for what ever reason? Have you tilt back the machine and checked the plunger? Maybe it is worn or broken - who knows. I´d tilt back the machine press the plunger and the turn the hand wheel and watch the stitch adjustment cam and plunger... Post a picture of the underside of the machine that's where all the mechanics do their work. Maybe someone can see an irregularity. -

You better write in English I once have restored a Durkopp 18 but no longer own it so maybe the video I have posted in the below linked thread may be helpful. Hope it helps.

-

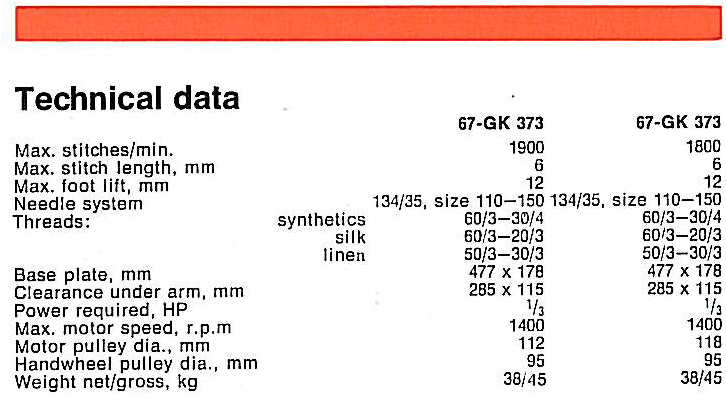

For the Pfaff look for the 1245 model - the 1246 is pretty much the same but with double needle. 1245 /1246 came in 2 different castings. Not sure is they had identical specs but I think so. https://www.pfaff-industrial.com/en/portfolio/sewing-machines/flat-bed-heavy-duty/pfaff1245?set_language=en https://www.google.com/search?client=firefox-b-d&q=pfaff+1245+site%3Aleatherworker.net%2Fforum%2F Adler 67 GK 373 technical data ex factory:

-

Amazon Affiliate-Marketing - click the links and someone who does not (necessarily) own the products gets paid and you get tracked by their cookies.

-

Thanks for your response. Sounds good to me. I sent them a requests yesterday but did not get a response yet. I have a hard time finding DOT snaps here (my preferred brand) and they even have some variants and some hardware that I could use as well. I hope to hear from them soon (before the UK leaves the EU ).

-

If you have mistyped and you mean a Pfaff 28 instead of Pfaff 29 then I have an English language manual as well as a parts list. Le me know...

-

Omega sewing machine question

Constabulary replied to Desircustoms's topic in Leather Sewing Machines

also - make sure the gib on the stitch length adjuster & the adjuster it self are correctly installed if not it may cause shorter stitch length. -

Good score! Its a clone of the Singer 211. It may have some minor differences but the "mother" of this machine is the Singer 211. EDIT: or better check for Mitsubishi DU-115 that's the MFG of this machine. Chandler just put their sticker on this machine

-

Omega sewing machine question

Constabulary replied to Desircustoms's topic in Leather Sewing Machines

reg. hand wheel engaging - do you have a manual and parts list for the machine? If not see below link Most likely the plunger for the hand wheel is stuck or the spring is defective or maybe even missing. Singer 29K71, 29K72, 29K73.pdf -

Whos Bernie? Sanders? What machine? What problem in particular? Thread size? Needle size? What means thick materials? Do you have some picture?

-

Maybe some UK or European members already have ordered here and like to share their experiences. https://www.opas.co.uk/ Thanks a lot in advance

-

okay so a 2" to 8" pulley reduction can do the trick then. But I would replace it with a servo.

-

Omega sewing machine question

Constabulary replied to Desircustoms's topic in Leather Sewing Machines

The pin is tapered and goes out from back to front. A few gentle hammer taps should drive it out if not rusted in place. Then remove the thumb nut and spring - done. -

You most of the time have clutch motors with approx 1400 /1500 rpm or 2400 / 2800 rpm. How many RPM has your motor if more than 1500 I would replace it no matter what.

-

Omega sewing machine question

Constabulary replied to Desircustoms's topic in Leather Sewing Machines

Good score for 300 CAD, I´d say. The green machine has a driven top feed but no needle feed. It should work well with garment leather. The 29K71 has a broken thread lever (easy to get and to replace.) -

AKAIK these are machines for cobblers. I once owned on of them (Frobana Brand) and I sold it again cause the cutter did not cut a straight edges and the splitter feed wheel left heavy marks on the leathers and mine had much finer teeth on the feed wheel. I do not think you will be pleased with it except you do cobbler work. Maybe others have different experiences.

-

Parts number is 237F - I´m not 100% sure if 237 is the same as 237F but maybe this may help you: https://www.singersewinginfo.co.uk/screw_threads