-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

But you know how to adjust the presser foot height on a 211, right? You need a screwdriver... The foot bar is the same diameter as on the 111 series. What I figured is that some Singer 211 (as well as some Dürkopps) have an extremely long brass presser foot bushing. IMO that's is just for limiting the foot lift (don't ask my why they did this) so even a 3/4" long bushing on top will be sufficient. If I were you I´d cut it down.

-

Nice thing on these vintage Singer work horses is that you still find unbelievable number of spare parts and accessories.

-

a 42 stitch bar tacker is what I´m looking for as well but unfortunately space is limited and to be honest with my self the number of tacks is "limited" as well . I´m using a ZZ machine - that works okay.

-

How much was it? Is it worth sending it back? Maybe asking for a partial refund is the easier way or maybe they even send you another (different) one for free when you send the pictures of the situation.

-

damn - jump foot + reverse... wrong side of the pond

-

Why are you ripping your machine apart? Just for cleaning? Not necessary. Generally such a long bushing is not necessary so when there is no technical reason other than limiting the foot lift I would cut it down or leave it and continue w/o removing the upper shaft. Ripping a vintage machine apart can cause trouble such as damaging parts which are (probably) no longer available. So be careful. My 2 cents.

-

How do I increase presser foot height??

Constabulary replied to HayleyMcJenno's topic in Leather Sewing Machines

I never have touched a machine of this type and brand. But looks a bit like the Juki DU-1181. I guess something should be mentioned in the manual. EDIT: I guess it is like this: https://www.manualslib.com/manual/1155862/Juki-Du-1181.html?page=12#manual -

some love them and seem to work after some modification - I would not touch it.

-

yes: https://www.ebay.de/itm/1PCS-Arm-Shaft-Connecting-Belt-fit-for-SINGER-107G-107W-140W-143W-457G-457U/162953960802

-

I have edited my post see above you quoted too fast Machine has no reverse. Make sure the timing belt is in good condition.

-

107w1 and 107w3 are pretty much the same machine. It may have had a different feed dog, needle plate and presser foot ex factory but that's changeable. Major difference is that the 107w3 makes a wider ZigZack (up to 8mm afaik) and you adjust the ZZ width on the rear side of the machine and not on the front side as on the 107w1. Both are zig zag high speed machines with drop feed and you can sew some garment type leather with them. They are not heavy duty machines.

-

the binder attachment in best case has to sit in the angled cutout in the needle plate in front of the presser foot (w/o touching it) so you probably have to grind down the foot a bit. Usually for the 69 so called shell binder are used but you may have differences among them as well so its not safe that they fit 100% into your setup. But I`m using the same binder type as you (different machine). But as Uwe said some it may require some modifications but thats not too unusual. On my bracket the binder is attached with 2 screws and and I can alter the angle.

-

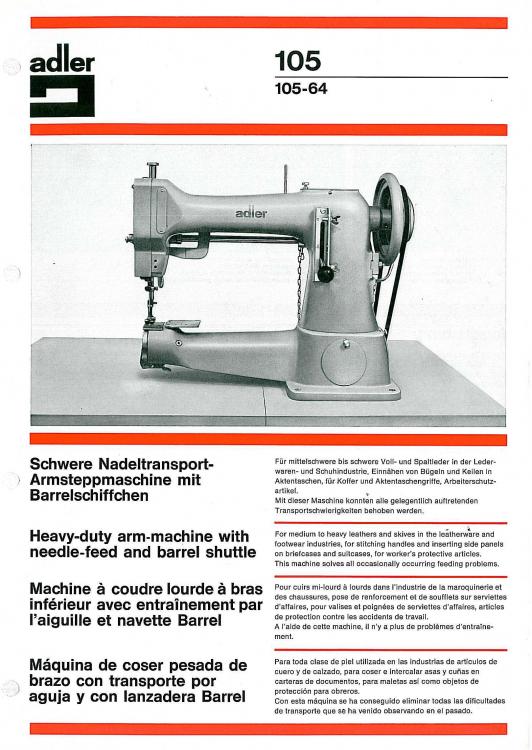

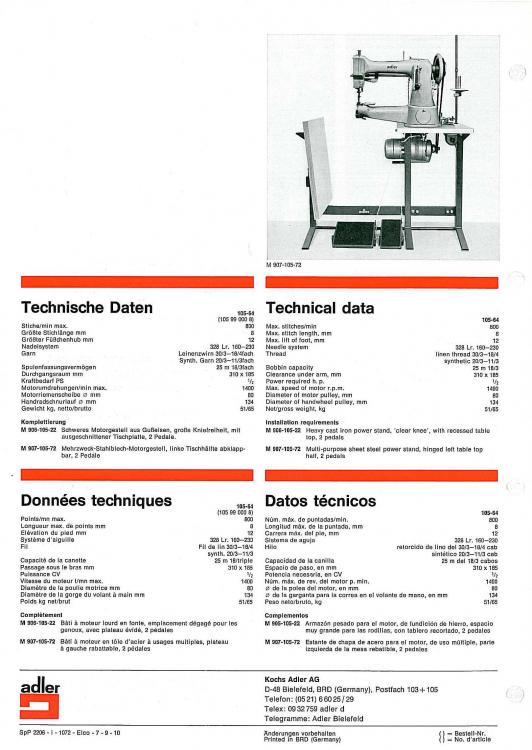

Difference between Adler 105-64 and Adler 169?

Constabulary replied to Wintersunset's topic in Leather Sewing Machines

The 105-64 is the heavier machine and has a larger hook, and can handle thicker threads & needles Its it a drop feed + needle feed machine. Here are some Data: -

singer 111g155 handwheel shaft size

Constabulary replied to chrisash's topic in Leather Sewing Machines

hope you have a small head size otherwise your blood sugar level may explode -

singer 111g155 handwheel shaft size

Constabulary replied to chrisash's topic in Leather Sewing Machines

I never measured it. I have to take off my hand wheel to measure... so... -

Have you probably tightened the end screw on the hand wheel shaft too much? Maybe therefore the hand wheel is pushing against the casting and is binding up.

- 5 replies

-

- sewing maching

- 132k6

-

(and 2 more)

Tagged with:

-

Direct Drive Servo Motor retrofit for vintage singer 491D

Constabulary replied to JClif88's topic in Leather Sewing Machines

For a while I have been playing with the idea of an NEMA planetary gearboxes like this: https://www.ebay.de/itm/Planetengetriebe-Drehzahlminderer-Nema17-23-34-Getriebekopf-3-5-8-20-30-40-50-1/264861653607 But when putting approx 120€ for a 1:3 planetary gearboxes + tinkering in relation to a DIY Speed reducer the DIY version was the winner. -

on manualslib.com you can download the manuals. But when you are online with a mobile phone you may have issues to read the PDF files because of the small screen (I guess). Reg. the link in your other thread - you have to be logged in to download the file. Your 51w56 seems to be the same as the 51w44 (and the like) but looks like your 51w56 no longer has the trimming device. If it helps - scroll down here for more info on the 51w56 http://www.industrialsewmachine.com/webdoc1/used/used-singers/51w.htm I attach two more files her, maybe it works better for you. 51W44.pdf 51w51.pdf

-

So do I - I never buy on Amazon except I cant find my item elsewhere. And at least on my end Ebay always was cheaper yet.

-

Buying form your trusted dealer is the best bet. However Groz Beckert and Schmetz no longer have a needle production in Germany. Sinze 2017 Schmetz is part of Groz Beckert. Scroll down to 19.05.2020 https://schmetz.com/en/news/what's-new/ So it could well be that the sellers of GB needles on Amazon and Ebay sell legit GB needles - but who knows for sure.

-

Hard to tell without sitting in front of the machine or having any pictures. Do you have a manual and maybe parts list for your machine to check if everything is in order / in place? F.I if the bobbin case retainer + spring are present and correctly set? You may adjust the needle - hook distance when the hook is defecting the needle. Or maybe needle bar is too high or too low. Are you sure you insert the needle correctly w. needle scarf facing right? You can download a manual in this thread, manual has a lot of setting values which should be checked.

- 5 replies

-

- sewing maching

- 132k6

-

(and 2 more)

Tagged with:

-

Same as Pfaff 335 (old casting) they are using the same hooks. They measure 22mm x 9mm Sample: https://www.college-sewing.co.uk/9033-bobbin-steel-pfaff-138-463-seki.html

-

Important Customs news for UK/Eu leatherworkers

Constabulary replied to fredk's topic in Marketing and Advertising

Sending an item as gift does not mean it will not go through the customs. Even low value package may be inspected - they are aware of the "gift thing" - trust me. That would be too easy. -

looks a bit like Singer 191 / 291 or the like, tailoring machine.