-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Speed reducer is the common term here for the above and similar constructions. You get what you pay for I would not pay big $ for a high end servo (like EFKA) cause I just do not have the out put that would justify this investment. The "cheap servo" and speed reducer combo works very well for what I´m doing. I´m very pleased with what I have.

-

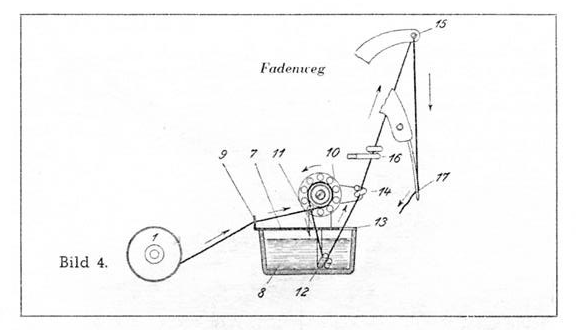

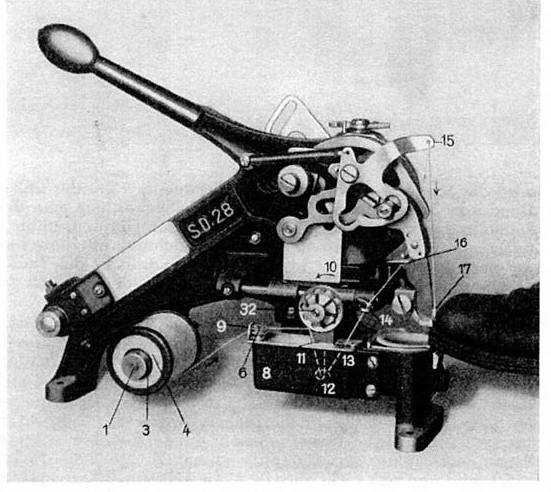

all motors start 0 RPM (of course) question is what is the next step. Most servos start working between 100 and 200 rpm - I guess 16 mean 160 rpm and 1 means 100 rpm I would add a speed reducer 1:3 speed reducer. I added SR´s to ALL my machines - its just gives you a much better speed control. A larger hand wheel / pulley on the machine is another option but to be honest I do not like that just for optical reasons but that's just me. DIY speed reducers are cheap you just need a 40 - 50mm pulley, a 120 - 150mm pulley, ~100 - 150mm long 15mm diameter shaft, 2 pillow block bearings, some scrap wood and some screws... Should be doable for approx 25 - 40 bucks (depends on your market and currency) . This is my DIY reducer I put on my 51w post bet set up.

-

I do not know the 42 class but I guess it is a beefed up Singer 16 (kind of) so it could be that the standard roller feet will work on this machine. If it has the larger diameter foot bar (like the 45K) then the standard roller feet will not work. Can you post some pictures and check the foot bar diameter.

-

the original link lead to a massive cast iron housing - no joke. Its now forwarded to a different add - note this at the end of the link when you click it: exAdID=1254798278

-

Please post pictures of your tension unit or better of your entire machine so we can see all the details.

-

29K´s usually work well with 138 thread. My short arm 29K71 can sew almost 12mm material (webbing io my case - leather is probably a different story) but that does not mean all 29K´s can do this. But to be honest the comfort zone for my machine zone is rather 5-8mm. I have pushed it to the max and I never sew this thickness but my machine it is able to if I have to. Running a machine at is limit will increase wear / shorten its life so I would not recommend this for a daily running machine. https://www.youtube.com/watch?v=7kF1feAFwdQ&feature=youtu.be All 29K have the same feed mechanism, they all mark the leather more or less depending on leather type, foot pressure and type of presser foot (fine teeth, coarse teeth...)

-

Really - no information? On my end Google delivers some good hits. Quite on top of the search results you find links to LW.net https://leatherworker.net/forum/topic/43014-singer-251-13-or-241-12-for-holster-leather/ https://leatherworker.net/forum/topic/69237-double-needle-machine-uses-singer-112g139-300w-1/ Basically - the 251 is a garment / tailor sewing machine and the 112G139 is an upholstery walking foot double needle machine for up to ~ 3/8" material but we do not know if your machine has been altered or not...

-

good idea - picking up the machine in person is even better!

-

Are you using the hand lifter lever or foot pedal / knee lifter? Usually the knee lifter or the foot pedal lets you lift the foot higher. But certain parts can limit the foot lift as well but is hard to tell when not sitting in front of the machine. BTW I can lift the foot on my 111G156 a lot higher than 1/2". I played with part settings but I`m sorry I have no instructions, I did this long time ago.

-

I´m not sure if Consew ever produced their own machines. AFAIK they relabeled JUKI, Seiko and probably other makes bur never produced machines by their self in a "Consew Factory". JJN - as the seller if he can measure the diameter of the bobbins - 22mm is the small / standard bobbin.

-

Well - you talked to both dealers so what other input do you need or expect? If it was me I would most likely buy from the dealer who is closer to me.

-

hmmm - looks complete but I think the needle is bent

-

Tooooo new for me to have any knowledge. I don´t know the differences.but maybe the 1422 is close... Pfaff 1422.pdf

-

Seems the difference between 255 and 256 is the stitch length adjustment, the 256 seem to have the old Singer 111 / 211 stitch length thingy with push down button in the flat bead and then adjusting the stitch length by turning the hand wheel and the 255 has a dial knob. Don´t know about the stitch length of the 256 but on the hand wheel I see a 4 - so 4 SPI at least I think. Looks like a rock solid machine in great condition I´d even guess its made by SEIKO, Japan.

-

If you don´t trust the shipping co´s take the machine heads of the stand and transport them in your own car. If that's not an option I´d probably secure the machine heads with tie down straps as good as possible

-

most likely a GA5-1 - google it. EDIT: https://leatherworker.net/forum/topic/41109-techsew-ga5-1r/

-

I make turns when the needle is further up and the hook has caught the thread loop. Open the slide plate / hook cover and hand crank your machine and check where the hook tip is when you make the turn.

-

if you need something from my side of the channel (Ebay or other sources) - let me know... Polyester Thread Ebay

-

The cover plate has to match the needle size (see German manual, picture 14, #36 and page 22 / 23, #251, #252) Maybe the plate is worn or does not match your needle size. Needle size should be marked on the plate (maybe not at the Pedersen - don´t know). have you pulled up the bobbin thread before you start sewing? Reg. tension have you wrapped the thread around the top tension wheel? Also, in one of your above pictures I see the thread is not on the machines spool post. Its coming from an external spool holder. Usually the thread spool is held on the machines spool post and is secured with a nut AND a spring., the spring puts some tension / drag the on the spool - maybe that's an issue - don´t know. Jimi gave that hint in his post already. #1 Nut, #3 spring

-

If it was me I would buy the Juki 563 because parts & accessories are easier to get and are cheaper too (Singer 111 based machine) and afaik the bobbin is a lot larger as on the 545. The Pfaff looks refurbished to me ( a bit strange color) and the stitch length adjustment thingy looks a bit strange to me as well..

-

Consew 226 - Centering needle left to right

Constabulary replied to RWL2's topic in Leather Sewing Machines

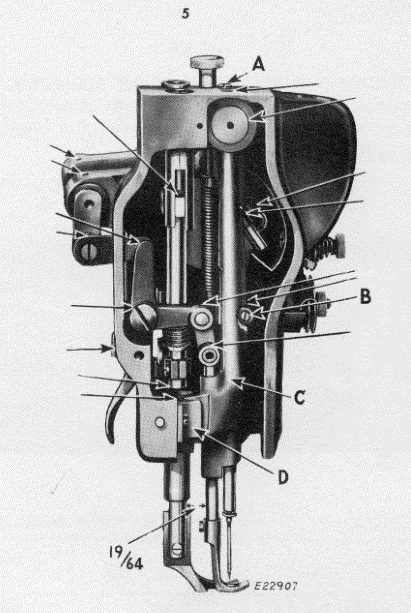

wild guess - is the needle bar rock frame (# C) loose and has play sideways or is set too far too the left? I´d check screw A (see picture) if it is loose - if not loosen it and try to push or carefully tap the pivot point stud (2 arrows below A) to the right and tighten screw A. Also reposition #D then. -

Foot or knee controlled reverse for Consew?

Constabulary replied to RWL2's topic in Leather Sewing Machines

I guess you are planing to make / buy a sewing machine table top for this machine, right? Then why cutting is off? Or do you want to use is in a different way like on top of a table... we don´t know what your intention is. -

Shuttle has to be sloppy - its is a so called elastic shuttle which is oscillating and the thread is pulled UNDER the shuttle while forming the stitch - it is just like a patcher shuttle just a lot larger. What kind of leather are you using? This machine is designed for stitching stiff / rigid shoe sole leather.

-

if you can´t find the Singer parts I would look for Seiko LSW series parts. Not sure which model is a direct clone of the 211 so you have to compare parts lists. If the LSW series has similar parts its very likely that they will fit your 211 as well. Maybe check with College Sewing again...