-

Posts

5,807 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

if you can´t find the Singer parts I would look for Seiko LSW series parts. Not sure which model is a direct clone of the 211 so you have to compare parts lists. If the LSW series has similar parts its very likely that they will fit your 211 as well. Maybe check with College Sewing again...

-

looks like the Ferdco 440 is a GA5-1 so if no one has tinkered it should be Needle System 328 / 214x1 or 214x2 for leather.

-

29-4 needle bar thread spring screw issues

Constabulary replied to Namlleg's topic in Leather Sewing Machines

Yes. But better compare parts number before you buy a new or used one. Machine will not properly work if the NB does not have this small spring. If the spring is worn (grove worn into the pedal) replace it as well. -

I guess the parts are the same due to the parts numbers I don´t think Singer double used them so seems the 300 share some parts with the 211. https://www.college-sewing.co.uk/270026-feed-reg-stud-spring-singer-300u-tapeedge.html https://www.college-sewing.co.uk/240245-retain-spring-singer-300u-tapeedge.html

-

Singer 31-20 or 31-15 painted white?

Constabulary replied to ellene's topic in Leather Sewing Machines

look at that - I knew Singer invented the Transformers Or is from the "Death Star" cobblers shop? Luke - I am your patcher... I have seen these machine housings with Adler 30 but not yet with Singer 29K´s. Kinda cool but a bit toooo fancy for me. -

Singer 31-20 or 31-15 painted white?

Constabulary replied to ellene's topic in Leather Sewing Machines

it obviously is a recently restored machine a with personal choice / mixed up decals. Decals most likely came from https://www.singerdecals.com/ -

Shipping issues...USPS coming and going

Constabulary replied to BruceGibson's topic in Leatherwork Conversation

Deutsche Post on my side of the pond no longer ships small packages to the USA - I can use DHL but have to ad "Premium Service" to all packages. So at the moment I ship with UPS. Just recently I shipped a package to a LW member and it arrived within 2 days - remember I live in Germany. Have to admit that I shipped UPS Express but still - 2 days over the pond door to door. Advantage of UPS is that they have their own airplane fleet. I think DHL / Deutsche Post outsources a lot though DHL owns airplanes as well but I guess they are blocked for "Premium customers". https://www.deutschepost.de/en/c/coronavirus.html#usa EDIT: BTW - have you guys ever tried a shipping comparison like: https://shipgooder.com -

A too small needle size or not enough top tenstion / too much bottom tension. But I bet your needle is too small for the 207 thread What needle size are you using?

-

So you are loosening the clutch on the handwheel and the needle bar is still moving? That should work w/o problem - all least that's how it is supposed to. I think you have to clean and oil the handwheel clutch and pulley bore or try to reduce the V-Belt tension a bit.

- 5 replies

-

- pfaff 138

- bobbin threading

-

(and 1 more)

Tagged with:

-

Handwheel hard to turn (speed reducer)

Constabulary replied to Doxnet's topic in Leather Sewing Machines

Depends on your motor if it has a mechanical brake or not. My Jack Servos have an electronic / magnetic brake which cannot be removed. -

Not my video I think but must be a video by "thesergeant" but I have linked it I guess. Stitch length can be limited by the feed dog lot and / or the slot in the stitch length dial. So a throat plate with longer slot + matching feed dog may help but post picture please.

-

Newly Aquired Adler 30-15 Need a Manual Needles and Bobbins

Constabulary replied to JJN's topic in Leather Sewing Machines

Ha - $200 is a steal - well done! Yeah, large bobbin is what I would like for my 29K71 short arm too but I'm barely using the machine, so I can live with it. There is no source for the Adler serial numbers but I'm sure yours is from the 1950´s - 1960´s. -

Newly Aquired Adler 30-15 Need a Manual Needles and Bobbins

Constabulary replied to JJN's topic in Leather Sewing Machines

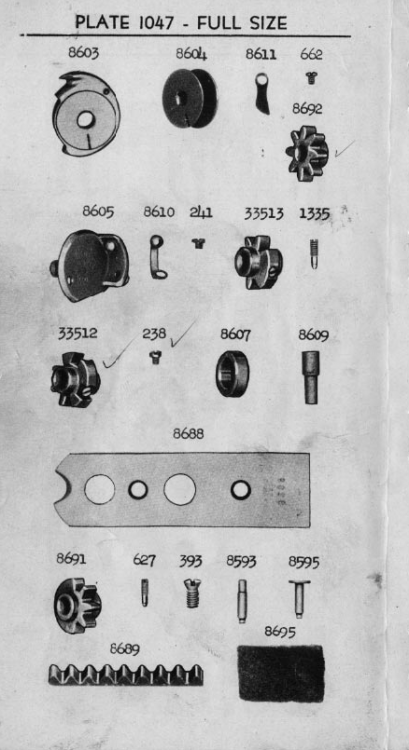

30-15 is a small bobbin machine. The large bobbin / short arm was the 30-17 which is rare! Bobbin and shuttle hooks for the 30-15 are the same as for the 29K models. Part numbers are 8604 (bobbin) and 8603 (shuttle). -

now I got it - just read the list and noticed 2 screws are mentioned... interesting. They do not mention a different shuttle carrier other than the 8605. So maybe a pinion for solving timing issues or so... I don´t know... You know what I mean? Maybe FleurFeroce can post some pictures of his / her shuttle carrier.

- 7 replies

-

- 33512

- singer 29-4

-

(and 1 more)

Tagged with:

-

Jimi - to me it looks like 1 screw but in a different position, usually the screw is placed in the center of the "beefed" section on the driving pinion but on 33512 it looks like shifted to the right - or not? Or do you think there is a 2nd screw left of the beefed section? I dunu

- 7 replies

-

- 33512

- singer 29-4

-

(and 1 more)

Tagged with:

-

would be good when you post a picture of that plate so the folks know better what you are talking about With "arms" you mean the long and short toothed rack, right? 33512 is the shuttle carrier driving pinion. I have the 33513 pinion but looks like the 33512 has the set screw in a different position, right?

- 7 replies

-

- 33512

- singer 29-4

-

(and 1 more)

Tagged with:

-

I would guess some retailers do it as customer service for customers who bought larger volume items of all kinds and you want to make sure he will be a returning customer... or so... Maybe resewing straps, replacing buckles... but repairing a dirty totally ripped horse rag - no way that this could be efficient IMO for a 50 - 100 bucks rug... or is it?

-

isn´t repairing such a f´d up rag not more expensive than making a new one? Tell the horse when he rips more rags like this you will send him on vacation to a friendly sausage maker. More worn rags make the sausages even more expensive (sorry horse riders...)

-

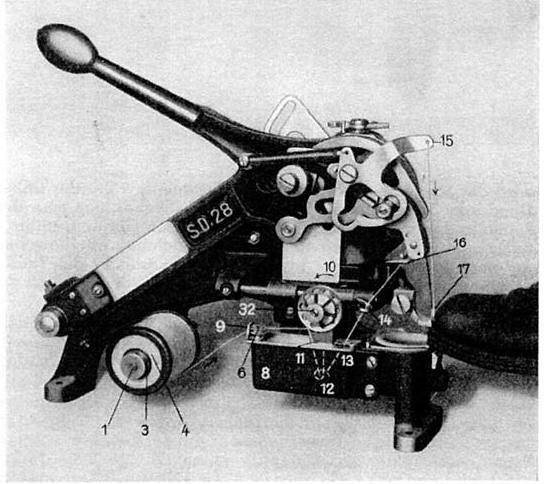

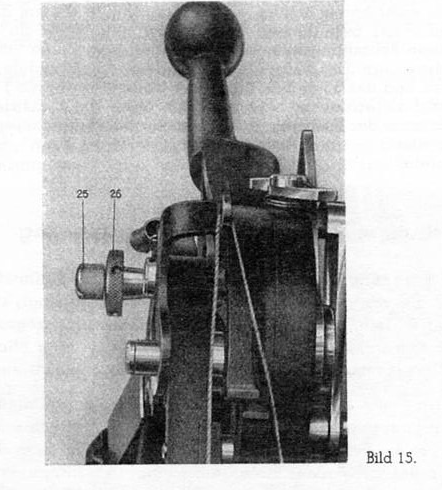

I once had a Junker & Ruh SD28 but it did not suit my needs. I was able to sew unwaxed 207 Poly + linen thread w/o problems (top + bottom). Screw #32 is for adjusting the top thread tension Screw 25 is for the stitch length BTW - I can send you a German language manual with better pictures - just send me a PM

-

Its a Pfaff 1245 clone as it seems. Someone tried to sell a ferdco in 2011 for 1250 - maybe that gives you an idea. However it depends on the accessories and motor (sevo... clutch...) and so forth... https://leatherworker.net/forum/topic/35305-ferdco-1245/

-

how about this one:

-

Not only in the UK. But aren't we all kinda guilty of that? And Corona will make it even worse. On the other hand you simply do (or did - mean before the www) not find certain things locally. No way for me to get my industrial Singer parts locally or even somewhere in Germany (sure, you can get some common parts but not really many) w/o making dozens of phone calls so my source is the www. Even for leather - I did not know a "full range supplier" for the leather hobby within a 50Km circuit. So before I drive longer distances and w/o knowing if I can get what I need I rather buy online from 2 or 3 different sources and often enough from the other side of the Channel (just recently copper rivets of a certain size). But to be honest I just recently found a supplier "quite local" (100km one way) and I never heard of him before / never popped up on searches. But for the moment I'm good with supplies. I hope I can visit him in a couple of weeks - really looking forward to that as he seems to have a lot of stuff I could use now and then. JFTC someone is interested: https://www.kappey.de/en/

-

The advantage of the 78 Class is that is has a very long stitch length of about 8.5mm whereas the 111 usually has about 5mm. Both machines do not have reverse if that matters. If you have the $ buy them both. If you do not have the space for 2 machines just keep 1 table you can use both machines on the same table (same size of cut out). The 78 has no feed dog, there is just a slot in the needle plate and that reduces the marks on the bottom side but that may not be too important in upholstery that's rather an advantage in leather work. But in instead the center feet often have heavier 2 teeth. I have a Class 78-3 on my shelf but haven't yet touched / restored it.... To me the78 looks like a very very simple and forgiving machine. It is technically reduced to a minimum IMO. But parts are hard to find nowadays. Nothing wrong wight antique machines, especially the 111 class series. I bought all my machines used and have even restored most of them. I like vintage machines A LOT! If I had too choose just one I´d take the 111.

-

I`m not sure what the problem is....

-

okay, did not know. So maybe some pictures of the current state of your machine may help. BTW - these 2 videos by thesergeant may help you a bit: https://www.youtube.com/watch?v=fdGD7D9QCUk https://www.youtube.com/watch?v=J9D5FLrxpLY As I said the 107w is very similar

.jpg.d60258221c476480a6e073a8805645bb.jpg)