-

Posts

5,809 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Plain foot for a Singer 78-1 and or Consew 28

Constabulary replied to sandmanred's topic in Leather Sewing Machines

Maybe check with Keystone Sewing, they have a bulk for 28 Class 78 machines for sale on their website so I guess they can sell some feet too. https://store.keysew.com/qty-of-12-mix-of-singer-78-3-consew-28-class -

sorry - my bad... link was for a slide cover

-

https://www.ebay.com/itm/Post-Bett-Slide-Platte-221215-fur-Singer-51W-52W-136W-138W-Nahmaschine-/16378209174 this slide cover should work - it even fitted for my decades old Singer 51w looks like they remained all the same.

-

if it was my machine I would try a Seiko CW-8 / Consew 227 / Singer153w slide cover # 13024. Not sure if it fits but thats most likely least expensive alternative I guess. Maybe worth a try. https://www.college-sewing.co.uk/13024-bed-slide-seiko-genuine.html https://www.teamworksales.com/store/p2048/13024-slide-cover.html

-

3/32" (2.4mm approx) is the distance between the 2 marks. The upper mark is when your needle bar is at bottom dead center and the lower mark is when you have risen the needle bar 3/32". So w/o the marks, bring your needle bar to BDC from there raise it 3/32" at this point the tip of the hook should be in the center of the needle 1/16" (1.6mm approx) above the needle eye. This video may help you

-

Keep in mind, the 29K33 is a very old machine and most of the wear parts are no longer available. Some parts are still available and some new parts can be modified to fit but its still an very old machine form approx the 1920´s I guess. Before you buy it look for a manual and test sew it. If the max. stitch length is approx 4mm its a quite good score for a machine of this age. if the stitches are longer - even better but when they are shorter you most likely have to invest in some new parts. The max. stitch length you can achieve is a good indicator for the technical condition / the grade of wear on this type of machines. Generally on patchers - yes, very handy machines for repair work and sewing in tight spaces or for sewing on patches but not a machine you can produce quality leather goods with.

-

Singer 16K SV 11 - I could not resist

Constabulary replied to Constabulary's topic in Leather Sewing Machines

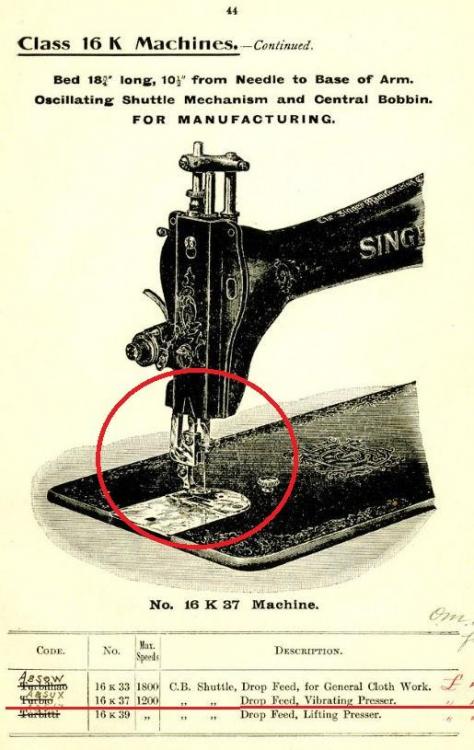

LW JIMI posted an interesting link in another thread so I just discovered the model on which this Singer 16KSV11 is based on (I guess). Class 16 machines start here: https://www.sil.si.edu/DigitalCollections/Trade-Literature/Sewing-Machines/NMAHTEX/2753/imagepages/image35.htm The "Standard Model" seems to be the Singer 16K37 (see page 44) which seem to have a vibrating presser foot and CB hook. So I guess the "SV difference" in case of the 16KSV11 is the heavy hand wheel the and long beak shuttle. -

Mr. Singer 45K & Smithsonian Website Sewing Machine expert.... Once again! Thanks again for this link - I found some more information about my Sinegr 16KSV11 - at least a machine that is close as it seesm. I will add the info to my thread. Thank you! I have to scratch your back - or are we even now?

- 8 replies

-

- sewing machine

- restoration

-

(and 4 more)

Tagged with:

-

I have service manuals / mechanics instructions for the 205 but files are too big to attach here. Please send me your email address by PM and I´ll forward them to you.

-

Singer 16K SV 11 - I could not resist

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Thank you I wish more members would post pictures of their vintage machines here. -

Singer 16K SV 11 - I could not resist

Constabulary replied to Constabulary's topic in Leather Sewing Machines

A few month ago I applied one of the original Singer decals I discovered once. LW member EVO160K did this on his Singer 45K too and I tried this the first time. Turned out quite well. The glue (MICROSCLAE MI-8) remains do not look as bad as on the picture, the flash makes it look "not so nice" but in real life it looks better. I could scrape it off but I leave it as is. -

Singer center feet have the screw from the backside and the Pfaff feet from the left. At least thats what I have experience so far. I´m pretty confident that the 2800 is using Pfaff feet. See picture (still frame from YT Video). However - no guarantee that el cheapo Pfaff feet from Ebay will fit. Chinese part tolerances may be slightly different so they may perfectly fit or not and you probably have to rework them a little bit.

-

Most common clutch motors run at either approx 1400 rpm or 2800 rpm. The 2800 rpm motors are rather useless IMO (with focus on leather worker or hobbyists). No one beside professional seamstress can really comfortably handle this speed. The 1400 can probably slowed down to a acceptable speed level with a speed reducer and you can sell them for maybe 20 - 50 bucks I´d say. But shipping them can be a pain because often people do not know how to pack up delicate heavy items properly (broken clutch lever or mounting base). But keep in mind if you sell them for 50 bucks and add the shipping thats about 1/2 the price of a modern servo and you (as a buyer) still have an old outdated energy consuming motor. Who really wants this nowadays? BTW - College Sewing in the UK kicks out their new 1425 rpm clutch motors for 28 GBP + tax. https://www.college-sewing.co.uk/1-2hp3pls-3ph-three-phase-low-speed-ho-hsing-clutch-motor.html That probably shows how the demand for clutch motors nowadays is. Of course - it always depends on your local market... If it was me I would most likely not buy a clutch motor for my personal use (meaning sewing) But maybe you or someone else can re-purpose them for other leather machines. Sometimes scrap yards buy old motors for the copper Conclusion: if it was me and the motors are 1400 rpm I would sell them for 20-30 bucks for pick up only other than that I´d take them to the scrap yard along with other scrap metal you probably have collected over the years (Some male folks have the tendency to collect metal parts for the "you never know" purpose - guess how I know )

-

Singer 108W20 - My New Binder Setup

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Well done! Yes, it is synchronized. There is small stud on the underside of the binder bracket / swing base which goes into the oblong slot in the feed dog. Distance from the center of the pin to center of the pivot point hole on the right side is ~ 8.4 - 8.5 cm. Stud sticks out ~ 4mm and is ~ 4mm in diameter -

Singer 108W20 - My New Binder Setup

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Don´t know where you are livi9ng but College Sewing in the UK seems to have the bits. Their shop is sometimes tricky cause not all parts are listed in the category they should be listed in. I think these are the bits but check the parts numbers first: https://www.college-sewing.co.uk/224702-cylinder-cover-singer-108k.html https://www.college-sewing.co.uk/224738-binder-swing-base-singer-108w.html If you are looking for other 108 parts look up the parts number or the machine class 108W or 108K it could well be thats the Pfaff 335 cover could fit Other than that this thread could be helpful for you to DIY one some LW members even have printed these caps -

Thats indeed a no go - I did not know the casting is that low. This usually works w/o problems but of course there are too many machines out there to know all their specs.

- 4 replies

-

- pfaff

- cylinder arm

-

(and 1 more)

Tagged with:

-

not my cup of tea but I would have bough them too. There is a sewing machine museum in the Netherlands and the guy (afaik) has this type of machines too I think it is this guy here but I´m not sure: http://www.naaimachinemuseum.nl/ maybe worth checking with them

-

Thats the often trouble with vintage machines. But to be honest I was not aware of that Pfaff did such significant technical part changes. This once again confirms me to be on the right path with my "Singer craze" . Even for the freakin oldest machines (not all of course) you still can find some new parts or parts are even interchangeable between different machines from different ages. But I don´t want to bash Pfaff - excellent machines - no doubt but parts situations can be tricky as it seems. Hope you can finish your project soon. If you see something on Ebay Germany and seller will not ship international just let me know

-

Does it have a parts number? Just from the shape it could well be for the 132K but Singer 31 feed dogs look very similar but are of a smaller site.

-

You can adjust the needle bar to accommodate the 135x16 needles. Compare the needle length and raise the NB by the amount the longer needle is longer than the shorter on measured from right above the needle eye up to the end of shaft (not to the needle tip). But you probably have to fine tune thew NB a little bit. I have set most of my machines to 135x17 / 135x16 so I do not have to stock endless needles types and sizes and in worst case even mix them up . It's s a lot easier when all machines are using the same needle system. My 2 cents

- 4 replies

-

- pfaff

- cylinder arm

-

(and 1 more)

Tagged with:

-

I would not buy it if it has no shuttle hook. I guess it is a HENGSTENBERG made (or rebranded) patcher. Bobbins can be reproduced but shuttle hooks for this type of patcher are 90% obsolete. With some luck the modern CLAES shuttles fit but they cost new an arm and a leg and it´s not safe that they will fit at all. There were literally dozens of different patcher hooks back then. Just to give you an idea... See below list of "Elastic Shuttles" for patchers. Or sell this machine to LW member SHOEPATCHER - thats probably the best bet! EDIT: see 3rd picture for a Hengestenber factory plaque

-

Correct Bobbin Case Size for Thor GC-1541s

Constabulary replied to rchaven's topic in Leather Sewing Machines

Most likely the parts come from different far east manufacturers and they may have slightly different specs / tolerances - you can have this with car parts too - some perfectly fit and some don´t even when the parts # is the same. Guess why Singer always had an add in their manuals Good old days - but these days are gone - just as Singer. -

Singer 51W SV 2 Post Bed Machine Restoration

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Went back to a plain foot - works better for my purposes. So here is a quick & dirty YT video just to show how well the old 1975 dated 250Watt Moretti motor in addition of a 1:3 Speed reducer performs - really love it! It´s just about the performance, not the seam quality -

You most likely have an old outdated clutch motor. I would replace it with a new servo motor and add a speed reducer. Do a forum google search like this: https://www.google.com/search?q=servo+speed+reducer+site%3Aleatherworker.net&ie=utf-8&oe=utf-8 lots of different solutions in terms of speed reducers. Some DIY some out of the box from sewing machine dealers... lots of options.