-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Adler 48 are funny little machines but the bobbins are really small (somewhere between Singer 29K small and Pfaff 335 old style). They share the same hook with the Singer 17. I can send you and english manual for the 48 and a German language sales brochure showing different subclasses of the 48 but don´t ask for a translation. Send me your email address by PM if you are interested. I had a 48 class machine but not the 48-4. AFAIK the 48-4 foot is a jump foot and is not driven just as on Singer 133K8 and Singer 31K19 and the like.

-

-

can´t speak for the 7-55 but on my previous 7-10 there was kind of a bell crank lever with cam on the back side which controlled the foot lift. let me see if I still have pictures...

-

separating 29K71 body from foot HELP!

Constabulary replied to niles's topic in Leather Sewing Machines

taking too much apart can sometimes cause issues. When I restored my 29K71 I did not separate the castings and left the top shaft installed. No issues. -

Can anyone help me find this take-up lever

Constabulary replied to iron1951's topic in Leather Sewing Machines

-

As Jimi said - to me it also looks like the top tension unit is missing. I only can see the thread loop but not the tension unit.

-

Thanks a lot folks Jimi, the machines are not for sale but I indeed ha have to "rethink" the space for my machines maybe I can cut my bed in half or I can put one in the bathroom - who needs a shower when you have a rain barrel or lawn sprinklers @ scoutmom I cut out 5" in the middle of the 2 bars, drilled some 2" deep hole in either half (3x 8mm on the rear bar and a few more 6mm holes on the bottom bar) filled the holes on either side with JB Weld and insert 6mm thread rods (rear) and 4 / 5mm dowel pins (bottom). Why dowel pins and thread rods - well I just used what I had - no special reason. Make sure the holes in either half line up as good as possible but since the holes ware wider than the diameter of the rods / pins you still can adjust them a bit. Join the 2 halfs, line them up with a water level or what ever you have and clamp them to a table, let JB cure for a day - done... Its for sure not as strong as the old cast iron but it works.

-

I took sooooo many pictures while puzzling together this setup but most pics turned out to dark. Tried to brighten them but they were just too dark. So here are just a few of the done setup. Now this is my setup for the 51wSV2 post bed machine I have restored and I also want to use my 107w1 and 143w in this table. Wanted to have a smaller foot print stand with folding extension. So I cut down the center bars by 5" and glued them together with JB Weld and some thread rods and dowel pins (can post pictures if someone is interested). The new table top is beech wood oiled with boiled linseed oil - that makes a nice warm vintage look (looks much better in real life). I added a DIY 1:3 speed reducer and the motor is a 1975 made Italian OCEL / Moretti step motor (I think it is called step motor - we say "Anlassermotor" - its not a servo motor). Works very well so far but I´m not sure if I will keep this motor but I will test it for a while. Some pictures... When I was done and insert the 3 machines one by one I figured I had to make a small correction in the cut out... and then... the router guide moved Have to fill it with some wood filler

-

Can anyone help me find this take-up lever

Constabulary replied to iron1951's topic in Leather Sewing Machines

ooooouuuh.... I have a few old take up lever but I doubt I have one like this... will check... -

Service & Repair manual Singer 29

Constabulary replied to chrisash's topic in Leather Sewing Machines

R 1022565 - you looked too far up on the list this is a 7 digit number not 6 digit (w/o prefix) - go further down in the list -

Service & Repair manual Singer 29

Constabulary replied to chrisash's topic in Leather Sewing Machines

look again - on the 29K15 you probably missed a digit and the BC is rather an EC -

Service & Repair manual Singer 29

Constabulary replied to chrisash's topic in Leather Sewing Machines

this may help you to date your machines: http://ismacs.net/singer_sewing_machine_company/serial-numbers/singer-sewing-machine-serial-number-database.html -

Service & Repair manual Singer 29

Constabulary replied to chrisash's topic in Leather Sewing Machines

you either have to take off the head and disassemble it or - in come cases - there sometimes is a hole on the underside of the bulge where the threaded post sits in and you can hammer it out from the underside -

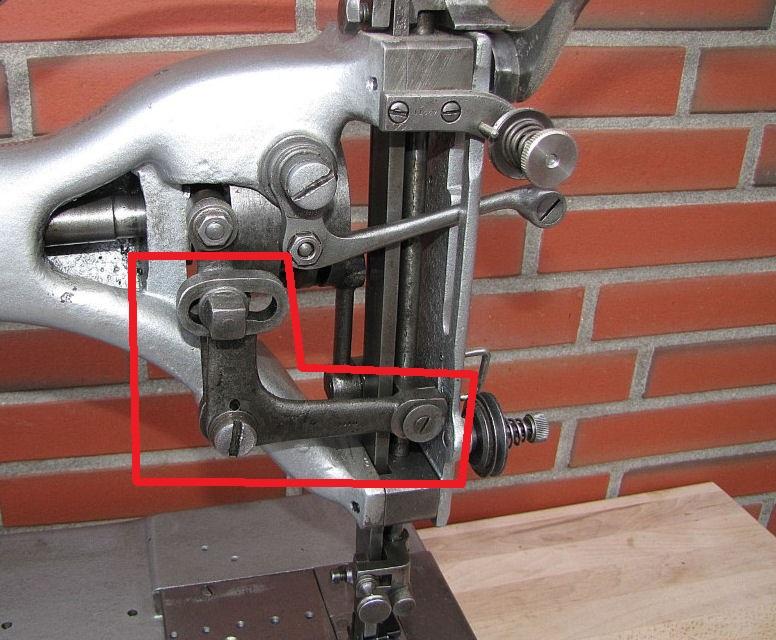

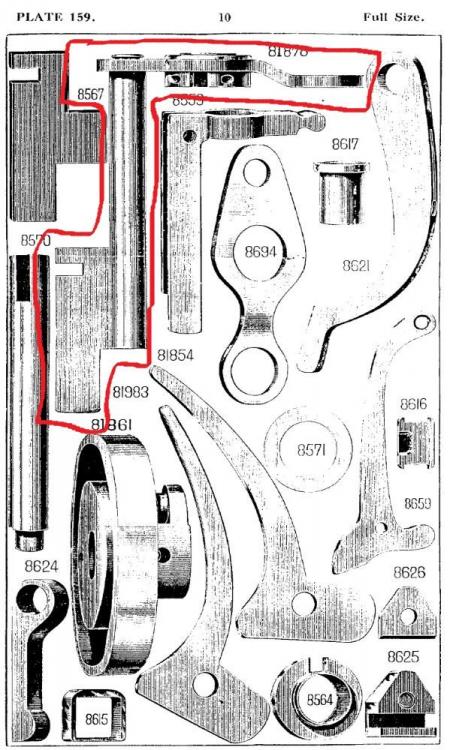

Bert, the inner round part rotates. I think I have one from a 29K33 - not sure if it is the same part. Looks like your part has # 8570 stamped on - or not? Below pic from a 29K1 - 29K33 parts list parts # here is 8567 and thats the part I have. I´ll post a pictures later...

-

okay - I have two screws but they are not the 207 I think but both fit in place. One is a bit too long but that one has a wider screw head like the 207. sooooo - dja want em? Will check another box tomorrow maybe I find something closer...

-

Maybe this helps https://leatherworker.net/forum/topic/76830-source-for-type-i-bobbins/

-

let me check - I may have one but be patient...

-

maybe this Singer 111 sales brochure gives you an idea - try to compare the listed values (SPI, foot lift...) with the actual machine: Download link: https://leatherworker.net/forum/applications/core/interface/file/attachment.php?id=163742

-

Cowboy CB3200 forward and back Stitch misaligned

Constabulary replied to palvim's topic in Leather Sewing Machines

wild guess - is it possible that the machine is just skipping a stitch in reverse? Its very unlikely that the F & R stitch length differ by exactly 50% (as it seems). Is it possible that it is just a needle / hook timing issue? -

Durkopp Adler 205 lubrication tubes

Constabulary replied to mloser's topic in Leather Sewing Machines

some pictures may help... -

Pfaff 1245-706/47 6/01 CLPMN hook saddle retrofit

Constabulary replied to mcguyver42's topic in Leather Sewing Machines

Do I get you right - you fear you have a wrong hook saddle because of the color? Why do you think the color is important? So other than the "wrong" color there is just a gear missing, right? I would probably check with Keysew in PA or College Sewing in the UK https://www.college-sewing.co.uk/9101912090000-bevel-gear-pair-genuine-pfaff -

I`m always using rattle cans for painting machine castings When ever possible I would leave on the old paint as long as there is not too much rust or the paint is badly flaking off. There is no better primer than the old sewing machine paint - especially the old black paint. BTW - make sure you remove the paint from the contact areas between top and bottom fasting and so forth...

-

Singer 133K - Information Wanted

Constabulary replied to Constabulary's topic in Leather Sewing Machines

I have been sewing webbing with it but I replaced the machine with a Singer 45D91. I usually have sewn with 4-6mm stitch length. Regarding tools - well it basically was a couple of screw drivers. I cleaned the internal mechanics with paint thinner. Spare parts you find galore at College Sewing in the UK: https://www.college-sewing.co.uk/parts-by-machine/singer-sewing-machine-parts/singer-132b-132k-133k-parts Seiko SK-2 and Mitsubishi DY253 are similar and share a lot of parts. Mechanically... well I replaced a few parts like check spring, bobbin case retainer spring and feed dog the rest was cleaning, painting and needle / hook timing and smaller adjustments here and there. If you want to restore your machine please open a new thread for it. Check this thread there is a manual for the 132K6 flat bed version linked but the needle /hook timing values are the same as for the 133K8 cylinder machine. -

Beast? Heavy? You will be surprised what "real" industrial sewing machines weight when setup with motor and so forth. The 127 is rather a dwarf compared with "real" industrial leather sewing machines.