-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Dürkopp 18 Patcher Restoration - long journey...

Constabulary replied to Constabulary's topic in Leather Sewing Machines

I do not know what 215AH / 657H is but don´t let just the numbers confuse you! Just as a sample: A system 81 needle is not the same as 81x1 needle. 81 is for patchers (Like Claes 200-1, 200-2, 8345-1 8345-2...) but he the 81x1 is a much shorter needle for serger machines (singer 81, Adler 81, Mauser...). Better check the measures! EDIT: just found this regarding 215AH so they pretty much the same as it seems - I guess the 215 AH has a scarf and the Sy. 88 does not (not sure though) https://www.strima.com/215-ah-suk-110-schmetz-sewing-machine-needle-g04-1box-100-pcs/item-309798 EDIT II: My 657 has no scarf but a longer tip than the 88 that's the only difference I can see. -

Would be great - looking forward to seeing / downloading it

-

Dürkopp 18 Patcher Restoration - long journey...

Constabulary replied to Constabulary's topic in Leather Sewing Machines

System 657 is like the System 88 needle but 657 has a longer tip - thats all. They are interchangeable. I somewhere have a pack of 657 I think. Let me check... -

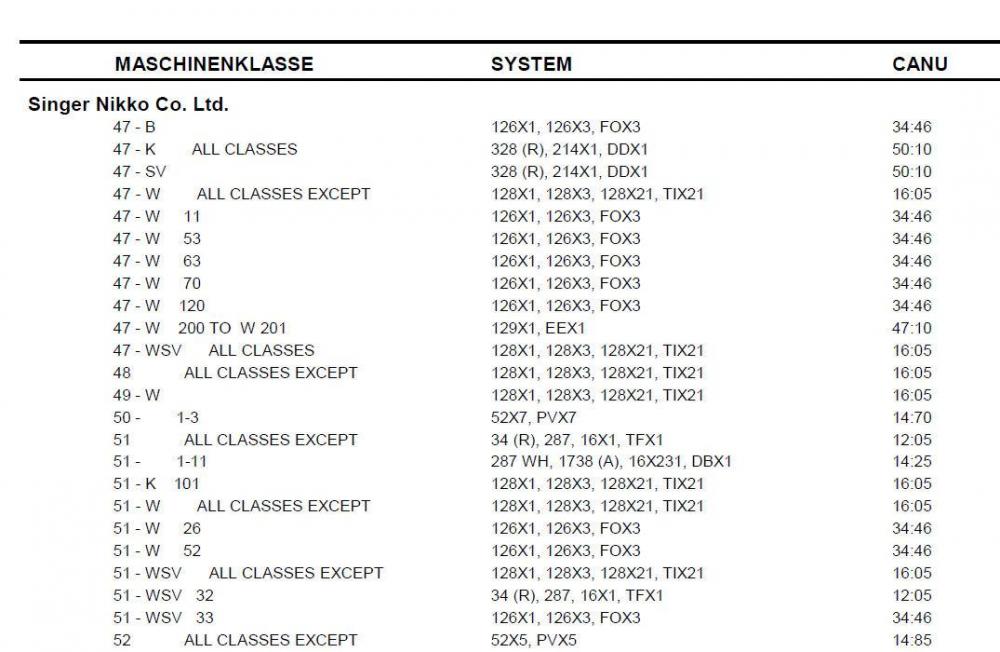

A quick google forum search gives you a lot of information about the 51w https://www.google.com/search?q=singer+51w+site%3Aleatherworker.net%2Fforum%2F&ie=utf-8&oe=utf-8 original needle system afaik is 128 but machine could be modified to accept other / more common needles. I have a 51wSV2 (early model) and I did a lot of modifications now mine is using 135x17 needles. EDIT: Here is an extract from a Schmetz needle list. The 51w40 in particular is not mentioned but you have an idea...

-

Reg. SD28 There is only 1 machine that needs this particular needle and the machine no longer is in production so its just a matter of time until needles are dried out. However lots of orthopedic / cobbler supplies wholesalers on my side of the pond have the SD28 needles but I cannot buy them because they exclusively supply the cobblers trade and no other businesses - not kidding. I tried 3 times to open an account and they did not sell to me - they do background checks as it seems. Again - a very special needle for just 1 single machine - so why should a dealer stock these needles? Just not enough demand. Even when there are 1000 machines worldwide... Most are ran by hobbyist I think so not really much demand there... But you can ask SCHMETZ to make them but afaik you at least have to buy 10000 needle of 1 size. So even when you are a dealer... 10000 (rather expensive) needles of 1 size for an outdated machine... and then try to sell them - shipping cost may kill the deal when someone just wants 10 or 20 needles or so. So you may sit on them for decades. I do not think it is economic for either party.

-

Well back then books where like the internet of old times (thats where knowledge came from ) nowadays you find technical data for the most common needles in the www. But of course not for the outdated / no longer in production needles cause no one really needs them anymore except some vintage sewing machine crazy dudes like us. I honestly don´t know what the difference between 1000H and 1000 is. I guess the shaft diameter or needle tip or position of needle eye could be different. Maybe some of the sewing machine dealers here have more knowledge (from old books).

-

Hope this helps but most likely not much - as I said the 124 and 586 are obsolete you may find some 1000 needles here and there but most are round point I think. As I mentioned in my thread reg. Adler III (linked in my 1st post)) - I have use 794 needles though the machine was meant for a longer needles - so they may work with your machine too when the thread loop is wide enough - maybe worth trying.

-

No PDF - sorry, the list is old and fragile and page will fall apart when I scan it so I´m sorry! But I´ll a take a picture... System 124 and 586 are outdated and no longer in production I think. System 1000 is most likely the only needle you can buy on the free market. Thats how it goes with 120 years (I guess) old machines. Welcome to the funny vintage sewing machine game

-

I have an old needle comparison list from METWAR. Based on your measures is could be needle System 124. alternatively I would try system 1000 or 586 but it maybe challenging to find them. I once had an Adler III and have used 794 needles with no problems but I do not know if the machined had a different needle bar

-

I have a German language Adler5 manual if that helps. Please send me your Email address by PM please. But the Adler 105 manual Bert has linked should help you as well.

-

SL 71 patcher problem bending bobbins

Constabulary replied to localleather's topic in Leather Sewing Machines

The bobbin is bent - really? Please post some pictures of the machine... more details... -

Bernina 217n-8 adding roller puller

Constabulary replied to Josacraw's topic in Leather Sewing Machines

I really can´t help here. For me it would just the other way around, if my machine had a puller I´d remove it - so I´m sorry. But Durkopp-Adler (or rather ADLER) also sold the Bernina 217 as Adler 1217 AFAIK - maybe that gives you an idea... -

Bernina 217n-8 adding roller puller

Constabulary replied to Josacraw's topic in Leather Sewing Machines

We have very few are sail makers here I guess and pullers are for sure not wide spread in Leather work . But to evaluate "the plate on the back" of your machine some pictures would be helpful. -

Looking for a flatbed attachment for an Adler 205-370.

Constabulary replied to thecruffler's topic in Leather Sewing Machines

Show & Tell: Flatbed Table Attachment For Durkopp Adler 205-370 (Version 2.0) - Leather Sewing Machines - Leatherworker.net -

Timing belt singer 108 w20 have to make it

Constabulary replied to maxraygreen's topic in Leather Sewing Machines

I have a 108w20, 143w2 (not 144w) and 107w1 - all have 35 teeth and the teeth are ~17mm wide and ~5.8 - 6mm long on all 3 belts. The spacing between the teeth on the 107w and 143w is 10.1 -10-2mm. I cannot take measures on the bottom side on the 108w ATM cause it is mounted to a table but when I measure on the top side of the upper pulley it seems to be 9.9mm - thats quite close but I cannot evaluate the amount of wear cause all machine have different degrees of wear. I think when the belts where equal they would have the same parts number. I´m pretty sure the 144w belt is wider, I guess like then111 type belts. approx 22mm BTW - in a German sewing machine Forum a guy installed on a 307G2 a new "industrial standard" upper and lower pulley (but he modified pulley bore) and a new timing belt maybe worth playing with this idea -

Timing belt singer 108 w20 have to make it

Constabulary replied to maxraygreen's topic in Leather Sewing Machines

College Sewing in the UK once had Singer 108 timing belts but seems they are sold (parts # 224513) but I would check with them if you cant find them in the US. Maybe you are interested in how I set up my Singer 108w20. I haven linked a parts list and a manual with instructions for replacing the timing belt in the 1st post: -

I have googled that for you and the 1st hit when looking for a manual for this machine is this: https://www.manualslib.com/manual/482501/Brother-Db2-B755.html?page=2#manual scroll down a bit and on page 2 you find the needle system. Google result for: Leather needle

-

Help identifying dial on new sewing machine

Constabulary replied to Laurajane's topic in Leather Sewing Machines

we do not know what brand or machine model you have but I´m pretty sure it is mentioned in the manual. Afaik it is for adjusting the foot height. -

I do not see any disadvantages in a 2 motion (back and forth going) feed dog. I had a 2 motion Pfaff 345 binder machine and it sewed just everything... The short stitches only happened when set up for binding and feeding too thick binding material through the binder but IMO this has nothing to do with 2 or 4 motion feed since both machine have needle feed. Thats at least what I have experienced with 2 motion feed dog machines. $800 in either case is a quite good deal when I look at the condition of these two machines and when I look at the pictures both seem not to be setup as binder machines. I would probably even buy both, maybe they do a package deal and you can make some $ selling the other machine. Condition really seem to be excellent. BUT - test them before you buy them! You never know how good or bad the motor is working - at least one seem to have EFKA motors and its expensive to fix them if they are not working properly. Pfaff is marketing their 335 model work leather work. H3 machines are usually set up for heavier material and have a foot lift of approx 11mm. EDIT: Just noticed the machine in upper picture has not stitch length lever but maybe its in the drawer.

-

Consew 206rb-5 Thread wrapped around bobbin holder

Constabulary replied to wulfjh's topic in Leather Sewing Machines

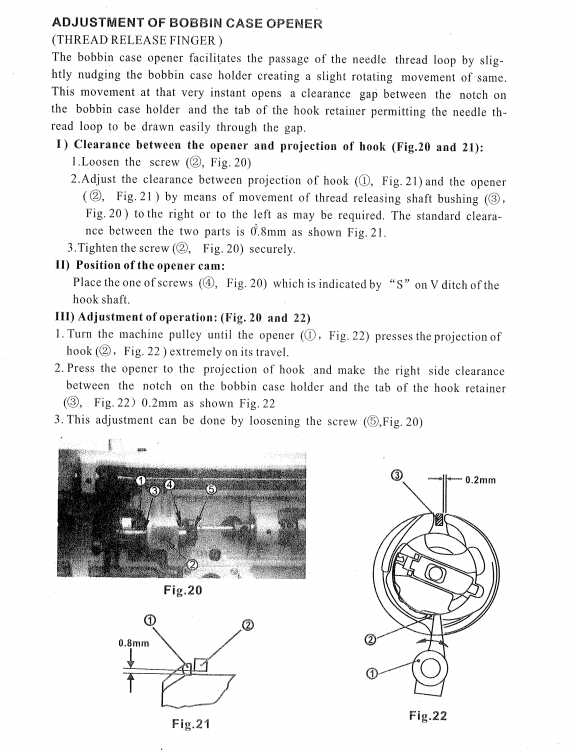

hard to tell from the picture but maybe t you have to adjust the bobbin case opener (mentioned in the manual) maybe gap between bobbin case opener / thread release finger and hook notch is too small. EDIT: -

Adler 467 with Efka control system

Constabulary replied to shaymus's topic in Leather Sewing Machines

Often these machines are setup to customers specs by different companies and you do not find a manual for a particular setup. I like tinkering too (hell, I do!) but wasting time and money and not coming to an end with a setup for maybe months is just senseless. Maybe check with MJFoley http://www.mjfoleyco.com/sewing/durkopp-adler/ -

Restoration for Juki LU-562 & upgrade to LU-563 Bobbin

Constabulary replied to Vinito's topic in Leather Sewing Machines

And how is it going here? Large hook installed? -

This is the Pfaff TU and IMO the position of the tension release pin is not really obvious I´d say but just for completing here is the OEM Pfaff TU

-

agree but this would not cause any of the shown issues I think, this is just a thread guide with a very weak spring. and have you checked the needle bar height? Not catching the thread loop usually is a timing issue, either needle bar to high (I still think this is the problem) or hook too far away form the needle (or both). If it was me I would lower the needle bar by 0,5 - 1mm and check again. Its easy to revise if this is not the problem. Loops at the bottom are either caused by too low or none top tension or a way to high bottom tension and this is a separate problem. BTW - your tension unit looks like it is put together from different (not OEM) parts. The tension disc are not Pfaff, there is a small pin cut away which would hold the OEM Pfaff tension discs in place ( Pfaff discs have notches). The tension release disc is from different machine too. I do not say this is causing the issues (but who knows when parts are bubba'ed) but I just wanted to have it mentioned. Question: is there a small pin inside the the threaded tension post which holds the discs spring and nut? EDIT: Picture shows a non Pfaff tension unit (principles are the same) but in this picture the position of the small pin is more obvious. So is this pin present inside the threaded post? If yes and it is too long (who know since your TU is bubba'ed) it could cause a tension release. Another question: are you using a knee lifter or foot pedal for lifting the presser foot?

-

https://www.google.com/search?q=flat+bed+attchment+site%3Aleatherworker.net%2Fforum&ie=utf-8&oe=utf-8