-

Posts

5,809 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

This is the Pfaff TU and IMO the position of the tension release pin is not really obvious I´d say but just for completing here is the OEM Pfaff TU

-

agree but this would not cause any of the shown issues I think, this is just a thread guide with a very weak spring. and have you checked the needle bar height? Not catching the thread loop usually is a timing issue, either needle bar to high (I still think this is the problem) or hook too far away form the needle (or both). If it was me I would lower the needle bar by 0,5 - 1mm and check again. Its easy to revise if this is not the problem. Loops at the bottom are either caused by too low or none top tension or a way to high bottom tension and this is a separate problem. BTW - your tension unit looks like it is put together from different (not OEM) parts. The tension disc are not Pfaff, there is a small pin cut away which would hold the OEM Pfaff tension discs in place ( Pfaff discs have notches). The tension release disc is from different machine too. I do not say this is causing the issues (but who knows when parts are bubba'ed) but I just wanted to have it mentioned. Question: is there a small pin inside the the threaded tension post which holds the discs spring and nut? EDIT: Picture shows a non Pfaff tension unit (principles are the same) but in this picture the position of the small pin is more obvious. So is this pin present inside the threaded post? If yes and it is too long (who know since your TU is bubba'ed) it could cause a tension release. Another question: are you using a knee lifter or foot pedal for lifting the presser foot?

-

https://www.google.com/search?q=flat+bed+attchment+site%3Aleatherworker.net%2Fforum&ie=utf-8&oe=utf-8

-

that looks like a tension problem - Which picture is top and which is bottom side? I guess the flesh (rough) side is the top side right?

-

Adler 467 with Efka control system

Constabulary replied to shaymus's topic in Leather Sewing Machines

OH MY GOD - to be honest if you do not need all the bells & whistles - remove them and buy a plain new servo motor. I tried to re set up something similar but different motor and I gave up just too much time and money and it was not worth both IMO. My thinking back then was wow - industrial sewing stuff... so cool, will be great to use... I soon dropped this idea and the whole thing went to the junk yard - just everything including the machine. This was many many years ago and I do not regret. And I tried it a second time with a Pfaff bar tacker - same thing... it went to the junk yard. Not worth my time and money. Lesson learned. Keep things simple if you can. -

Sometimes needle bar rise a little bit so w/o sitting in front of the machine I would guess you have to lower the NB a little bit. As I said before I would check the needle hook timing. Procedure is in the manual I have liked above.

-

settings should be the same I think. Are you sure you interst the needle correctly?

-

Since I see a white machine I guess it is the current 335 model. Here is a service manual for the current 335 model. It should help you with the settings: Pfaff 335 Service manual.pdf

-

different story but check this thread:

-

Often the problem is just an not correctly adjusted needle bar but hard to tell from the distance. First thing I would do is checking the correct threading and the needle hook timing. Are you sure the needle is insert correctly and using the correct needle system? I guess you have a manual for your machine, right?

-

The machine head seems to be refurbished Singer 29K71 - one of the best patchers you can buy IMO.

-

Not mine just wanted to share this. Something you don´t see very often nowadays. New in crate Singer 95K from 1950 https://www.ebay-kleinanzeigen.de/s-anzeige/singer-naehmaschine-neu-und-ovp-samler-einzelstuecke/1070067466-240-8654

-

How do I mount a Singer Treadle clutch?

Constabulary replied to DelNeroDesigns's topic in Leather Sewing Machines

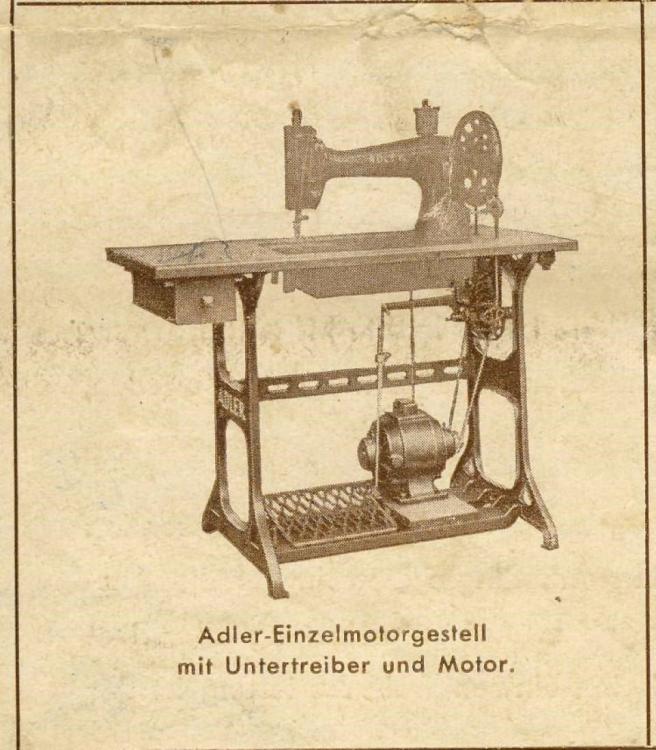

Some more pictures of a vintage setup (not mine) with separate clutch and permanent motor - sorry no better pictures. -

Looking at buying a machine but overwhelmed.

Constabulary replied to Brigeyboo's topic in Leather Sewing Machines

as far as I have researched, NO. https://www.wouros-partner.de/usa-ausnahmen-von-den-zusatzzoellen-fuer-sendungen-aus-china-mit-wert-unter-800-us/ they put a link and source at the end of the article. Google translate: https://translate.google.com/translate?hl=de&sl=de&tl=en&u=https%3A%2F%2Fwww.wouros-partner.de%2Fusa-ausnahmen-von-den-zusatzzoellen-fuer-sendungen-aus-china-mit-wert-unter-800-us%2F Importing goods from China to the US is not my business so please evaluate this by your self. However I would check with UPS or DHL Express in this regard in case you want to work with them. But IMO they are the easier way to import goods for small business. EDIT: cant´t read the full article but the headline pretty much tells the story: https://www.wsj.com/articles/tariffs-on-chinese-goods-are-skirted-by-some-u-s-shoppers-11577788201 EDIT II: https://www.ecomcrew.com/trumps-china-tariffs/ -

Looking at buying a machine but overwhelmed.

Constabulary replied to Brigeyboo's topic in Leather Sewing Machines

If I wanted to import a sewing machine form China I would do this with DHL Express or UPS. On my side of the pond they do the custom work when you provide them a regular invoice or commercial invoice (usually invoice is included in the package) and they (UPS or DHL) charge you the import fees, VAT and some fees for their work (about 10-20€ in case of DHL). They deliver the package / machine to your door when the fees are paid or they do COD. I don´t know how it works in the US but it would surprise me if it would work differently in the US. Question is how much the shipping will be. Check with UPS and check with DHL Express how they do the custom work and how much they charge. And AFAIK below $800 (not sure) they do not even charge custom fees in the US. -

How do I mount a Singer Treadle clutch?

Constabulary replied to DelNeroDesigns's topic in Leather Sewing Machines

Clutch goes under the table but theses separate clutches are for a permanent running motor drive not for treadle drive, you do not need a clutch when you treadle. So either do away the clutch and run the machine with a modern servo motor or if you want to use the shown clutch then mount the treadle stand on a wooden frame or wooden board where you can mount the permanent running motor. This is how a permanent running motor + separate clutch set up would look like. -

I just got a warning from Firefox (78.0.1) while opening LW.net. I think other users will experience this too. Warning on my end is of course in German language Seems the LW.net site is not supporting the current standard TLS 1.2 I had to reactivate TLS 1.1 to access this site. Just wanted to have it mentioned.

-

Adler 268-273 accessories , where to buy?

Constabulary replied to Bananaman's topic in Leather Sewing Machines

I haven´t yet touched a 2 needle post bed machine but I´m pretty sure you have to stick to your setup and cannot use singe needle feet because none of the needles is centered on the needle bar and the needle hole in the feed dog is also not centered (meaning in line with the foot bars + needle bar). You can remove the left or right needle and use the machine as single needle machine but thats almost it I´d say. You may (or may not ) find so called gauge sets for your post bed machine for using different needle spaces but expect high $ ($$$$$$$$$$$$$) prices and you have to change a lot of setting (f.i. moving the left and right posts - if that is possible at all). Even when you change the entire needle bar (to have a centered needle) you will not find single needle throat plates and feed dogs for a double needle machine. You probably can modify the existing foot set or buy a 2nd foot set and modify them for single needle use... Post bed machines with double needle are very special! Just my thoughts... EDIT: Maybe KHSEW.com has something... not sure what exactly fits thew 268 https://www.khsew.com -

maybe it is set up for 207 - I don´t know. Sometimes needles from different machines mix up and find their way into the wrong accessory box. You would not believe what I found in accessory boxes. Best find was a Luger 08 wrench / take down tool (not kidding).

-

some do some don't. I have seen an OEM manual where its mentioned that the machine is sewn off in the factory with #11/3 metric thread which is equal to 207. Needle plate hole has to be wide enough and the thread hole in the hook as well to run 207. Some other fine tuning may be required. 138 is possible all day but 207... you never know... I would not expect it.

-

I have two JACK servos one came with a 13mm shaft one with a 15mm shaft. Back then someone milled a pulley for the 13mm shaft (did not find any 13mm bore pulleys back then). An easier task is using a tube with 15mm outer diameter and 1mm wall an make a sleeve for the shaft. I did that on a different project - works perfect. If my next JACK servo has a 13mm shaft I will use the sleeve workaround again. Just my 2 cents.

-

I have a mechanics instruction for the Class Adler 30 but file is too big to attach here. Send me you email address by PM and and I can forward it to you. Basically you have to remove the tapered pin which attaches the needle bar to the slide piece on the lever arm tip (hammer it out back to front - in best case 1 gentle but feisty hammer strike should do it), loosen the stop thumb screw on the front side of the head (if present if not go ahead) then remove the 4 screws which hold the head to the main casting. Now the head is free. Pull out the needle bar from the bottom side. Then remove 2 small screws you see on the round cap piece the needle bar goes through. When done you should be able to pull out the revolving inner part from the bottom or push out from the top.

-

Base model is the Singer 211U which came in a lot of different sub classes. Open the right slide plate and remove the bobbin - is approx 25mm (or larger) its a large bobbin if 22mm its a small (standard) bobbin. These machines usually sew up to 9mm some up to 12mm depending on how it was set up. Best bet is test if before you buy it.

-

I know what you mean - I´m a tinkerer too but certain things are just not worth to DIY. Don´t underestimate this cap. Its not just a cap it also has a tension spring which is held by 2 tiny (and I mean tiny) counter sunk screws. It´s a precise part. It never ever would be worth the time making one but if you like it why not go ahead. The 29K2 is a different story because lots of parts are obsolete. The shuttles BTW you can get from Ebay for bargain prices this would not be worth the time as well but again - your time. Good luck.

-

When you find a "complete" machine for a very cheap price then in comparison new spare parts will always appear to be expensive / overpriced. Thats normal. But you have sewing machine dealers in CA too. I´m sure there is one who can supply these caps. You do not find everything online. Not all brick and mortar dealers have a web shop for parts on their homepage. When you are into tinkering (like me) you probably can replace the entire hook with a new made "el cheapo" Chinese hook. I do not have an overview of all post bed machine and their hooks but I guess most of them are pretty much the same. Especially when the machine is based on a Singer model. I have replaced the hook on my approx 1920´s / 1930´s Singer 51w with a Durkopp hook (Durkopp & Singer share lot of parts) I had floating around (actually form a flat bed machine). The OEM hook had a cap like yours. The new hook is a drop in hook. But thats not everyone's cup of tea its probably trial and error. But here I agree with Wiz - bite the bullet and buy the cap - fire and forget... done.