-

Posts

5,807 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

ESTO brand Leather & Plasitic trimmer

Constabulary replied to LomaeArts's topic in Leather Machinery

maybe you should post some pictures... -

me too - I press F5 (refresh) and its gone afaik there is a PHP error reporting in the backbend and you can set it to "Public" "Moderator" and "Hidden" - could it be that it is set to "public"? So everyone can see this error? I at least know that some web shop backends have this.

-

send me your email address by PM and and I can send you the manual.

-

Which Frobana do you have - this one: http://www.sieck.de/en/machines/new-arrivals/?produkt=8170 If it is the above I may have a manual.

-

Have I reached the limit of my Durkopp 239?

Constabulary replied to toxo's topic in Leather Sewing Machines

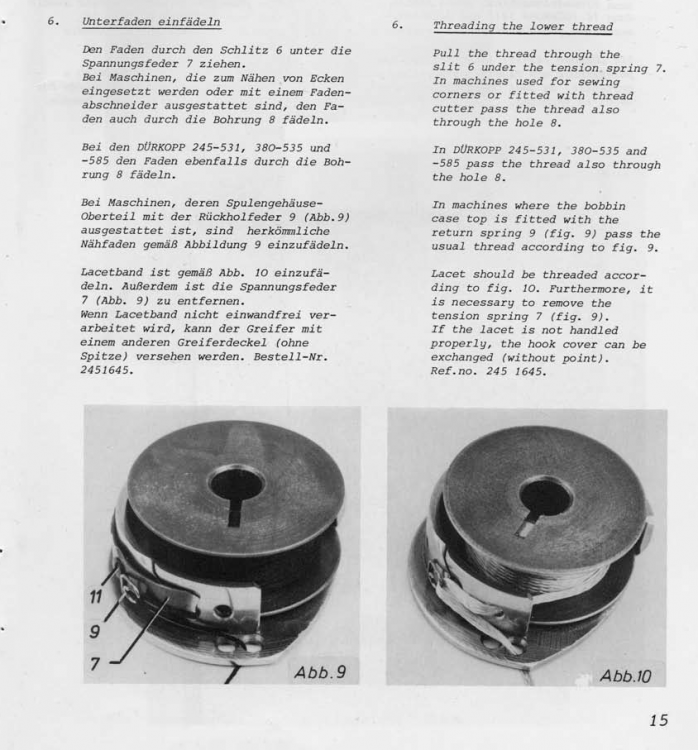

They "later type" Durkopp (Large hook) 245 /239 and other machines of this class seem to be able to sew with "lacetband" (braided flat thread) the hooks are prepared for that or special bobbin case caps can be ordered but I have no further experience with this. The extract below is for a later type 239, 245 (and other models) manual. They usually use all the same type of hook (large bobbin with bobbin cap) and I´m sure you you can install this hook to other 239 models but some modification may be necessary. if someone needs the complete manual, it can be downloaded here: https://www.duerkopp-adler.com/export/sites/duerkoppadler/commons/download/public/380/B_238_239_245_249_372_380_541_DE_EN.pdf -

How about RENIA Aqulim 315:

-

Bob - thats a parts list Niles - I have no PDF and the original manual is written in old German letters and the "spoken German language of the old days" is quite different to what we speak today - not sure if you can read it. I give you a sample.

-

wow - what a beast! Are you using a cutting board of some kind made of Polyethylene or wood?

-

See picture: remove screws A+ B then turn the hand wheel until the the hole in the shuttle carrier passed the needle hole in the arm tip then push the shuttle carrier down if the box does not free use a small screw driver as lever and kinda "jiggle it out" then remove screw C That's from a German 29K51 manual. I have not touched a 29K51 for a long time so I hope this helps... Basically - the gear box only drops out when the shuttle carrier is in a certain position. BTW - be careful with the pinions - replacement are not available anymore - the pinions you find on eBay and elsewhere DO NOT FIT because the have a different size and teeth!

-

I guess your gearbox is still in the machine, right? The 29K5x (except 29K58) series have a "drop out gear box" so you have to remove the gear box first and then you reach the screw for the pinion. let me see if I can find instructions...

-

silver hammer tone https://leatherworker.net/forum/topic/72789-singer-45d91-restoration/

-

Kinda reminds me of my 51WSV2 seems they have a lot in common beside smine is a post bed machine. https://leatherworker.net/forum/topic/86292-singer-51w-sv-2-post-bed-machine-restoration/

-

You still can buy them - they work for Seiko SK-2 and Singer 132K6 but they are not cheap. https://www.college-sewing.co.uk/1404-97739-outer-foot-bar-seiko-132k.html Mitsubishi made or makes the DY-253 I would guess the parts is the same on their machine but I have no parts list and nothing I could compare with. Maybe the Seiko or Mitsubishi parts are easier to find on your side of the world. EDIT: when I looked for parts these folks sometime pop uop - they are on the same Island as you **kidding** They have 132K6 parts in their shop so I guess they can get thr presser bar too. https://www.sewingmachinesaustralia.com.au

-

Class 17 usually takes the System 88 needles - some take 332 LONG. Both needles have the same length but slightly different shank diameter. I would first try System 88 needles. Do not take 88x1 needle thats a different needle. https://www.thethreadexchange.com/miva/merchant.mvc?Screen=CTGY&Category_Code=NDL-88 http://www.shoesystemsplus.com/Claes-Model-30-Needles-10-per-pack_p_353.html

-

Pfaff 335 clone help needed

Constabulary replied to Scottish lass's topic in Leather Sewing Machines

I can tell you from experience that most of the time the seller / sender is responsible because of poor / not sufficient packaging. If something goes wrong they ALL claim packaging was good but the truth is most of them (not all) do not know how logistic works and how the packages or other shipments will be handled. I know both sides - shipping an receiving. I have shipped a patcher machine over the pond from Germany to the US and nothing happened! And I can tell you this machine incl crate (!!!) weight 120 pounds and it was not easy to handle by just 1 person. I also have shipped my extremely heavy BUSMC #6 from Germany to the UK. A proper packaging is always the key. You (as a sender) have to pack your goods the way they can withstand rough handling. Usually shipping Co´s have a hint in their terms and conditions that packages have to be safe when dropped from at least 1m height (if not 2m or more). Nowadays you cannot expect that packages got carried from A to B in "the most careful manner"! If you think your packaging is good just add some more extra padding material - and most important the right padding material. Foam flakes and bubble foil is not sufficient for heavy item! When shipped by freight forwarder I would always remove the machine head form the table top and pack it up separately and stow it on the pallet. Wen ever possible I would not leave the machine head on the table. When a machine is left on the table top it is always top heavy and can tilt over when moved with a lifting cart. If you cannot protect delicate parts and parts that stick out just remove them and give the buyer instruction how to put them back on - f.i. hand wheels, positioning sensors and stitch length levers. Better safe than sorry. -

also - do you notice the beeeeeeeep sound while he is sewing? It comes from the motor - I had one of these "beeeper" servo motors and I found it totally annoying and sold the motor. I could not stand it on longer projects. back then seller said it will disappear - but it did not! So check what motor you will have on the machine.

-

Jack servo shafts are straight.

-

Yes

-

Pulleys from Jack Servos are removable (I have two of em). The point is they do not supply smaller pulleys for this motor, so you have to modify a pulley with15mm straight bore. I guess thats why they say it is not removable. BTW why should it not be removable - some one assembled the motor and installed the pulley... so...

-

I made a sleeve for the shaft from 13mm aluminum tube with 1mm wall - easy task.

-

What kind / brand of motor do you have? A JACK servo from CS? They are removable but some have 13mm and some have 15mm shafts - guess how I know.

-

Do you have a manual? Maybe this one gives you some answers. SD 28 Junker & Ruh Outsole stitcher Parts list and manual.pdf

-

Dürkopp 18 Patcher Restoration - long journey...

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Its indeed a Class 17 but here are several subclasses. -

Ebay - YOUR personal data they share (and sell I guess)

Constabulary replied to Constabulary's topic in Computer Help

Well, I´m on Ebay since... for ever... and never had really serious problems. A few smaller problems yes but nothing that really hurt me. They take money, yes, but that's business, right? So I´m not bashing Ebay here. I just wanted to give a hint regarding personal data settings which were unknown to me. I would guess Amazon is even worse - I almost never buy anything on amazon but that's another story. -

Ebay - YOUR personal data they share (and sell I guess)

Constabulary posted a topic in Computer Help

Just found this site randomly (you have to log in of course): https://www.ebay.com/gdpr Site speaks for it self. But it´s of course up to you what you want to share or not. I opted out all of them now.