-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Excellent !!! The "new type" regulators are hard to find so maybe you could make a few more. Pretty sure sooner or later someone will need one of these. But not sure if it is worth your time.

-

beside the search options and BTT - the "restoration sub forum" idea came up earlier already. Not exactly sure but I think it came from Evo160K but the idea never has been discussed really. It´s up to the moderators... I´m the last who would say no - so I´m in!

-

When the 2 machines come from the same dealer he should be able to explain the price difference - maybe a different motor or an additional speed reducer... Also, look at the consew website, seems these machines can come in different sub classes and therefore different prices.

-

Maybe we should compile a list of servo motors that work with speed reducers of certain reduction ratios. Could be helpful when looking for a specific servo motor

-

What model is the cowboy machine? Check if the machines have the same specs f.i. needle feed , stitch length, thread thickness, foot lift, accessories and so forth... do they have clutch or servo motor...

-

I´m not a moderator but thats the point I guess, when you had issues with certain brands or dealers some more details would be nice.

-

Amazing simple Design! Have you downloaded the manual ? Really amazing simple! I doubt the oiling / lubrication would be an issue when motorized. I guess the CUB has a plain bearing. Singer 45K´s also have a plain bearing and no ball bearing and it is manually oiled. 45K´s can run at ~900 SPM with a very heavy hand wheel mounted. Even patchers can run at 500 SPM. But I doubt people would run a CUB at that speed even when motorized. Remember how slow you sew with your machines when sewing leather. How many SPM are realistic 100 maybe 150 SPM? The machine has one eccentric tappets and a gear rack / pinion combo that drive the machine I think it would withstand a speed of 100 - 150 SPM without problems If I would own a CUB I would motorize it and I would not worry about the lubrication when run at relatively low speed. But I would check with Weaver and see what they say.

-

Seems it depends on the installed motor if SR and EPS (or NPS) can work together. I remember a post here where a member from Germany added a 2nd magnet to the EPS sensor and solved the issue but I´m not sure if this works on all servo motors - I doubt this. I´m one of those who do not need at EPS (yet - but you never know).

-

Singer 153W101 bobbin case is stuck

Constabulary replied to Leslie415's topic in Leatherwork Conversation

I do not have a 153w but a 111G156 - same bobbin and identical hook. The bobbin case has a small "lifter" on the center post which should lift the bobbin when you open the bobbin case latch and this small lifter sometimes it even literally "throws out" the bobbin - not always but sometimes. It may depend on the bobbin and how well it is "designed" or if the lifter is worn or... A small work around is an anti backslash spring / bobbin case spring. They are made of very very thin spring steel. You can adjust the spring by bending it carefully and it is not adding a significant amount of tension. You put it in the bobbin case and it prevents the bobbin from backlash when sewing at higher speed and it also lifts out the bobbin a bit more - at least in my case. The spring I´m using is Singer Parts #108308 Some pictures: -

Just wondering - Is Solar Leather out of business? I just wanted to check one of their YT videos and figured there no longer is any content. Also, the website is offline and Facebook site is gone. And when I do a google search I get the info that they are "PERMANENTLY CLOSED". I don´t want to spread wrong information so if I´m wrong please delete this post.

-

reassemble the machine and shoot a new video - w/o needle plate / throat plate it will not feed the material because the inner foot is lifting when the outer foot is touching the needle plate. When no needle plate is installed the inner foot will stay on the feed dog. Or am I wrong?

-

or maybe it was a sewing kit

-

Well don´t blame the market place, blame the seller. I had 99.5% good experience on Ebay. You can have shysters in local brick an mortar stores, on Etsy, on Amazon, craigslist or elsewhere - again, its not the market place its the seller. But I agree - that seller mus be color blind - any response from them? Never heard the word shyster before, had to google it - reminds me of the German "Scheißkerl". Have to save it in my vocabulary book.

-

Measures? Just from looking at the pictures - maybe a shaving brush holder - kind of... If it is of a smaller size maybe a needle reservoir?

-

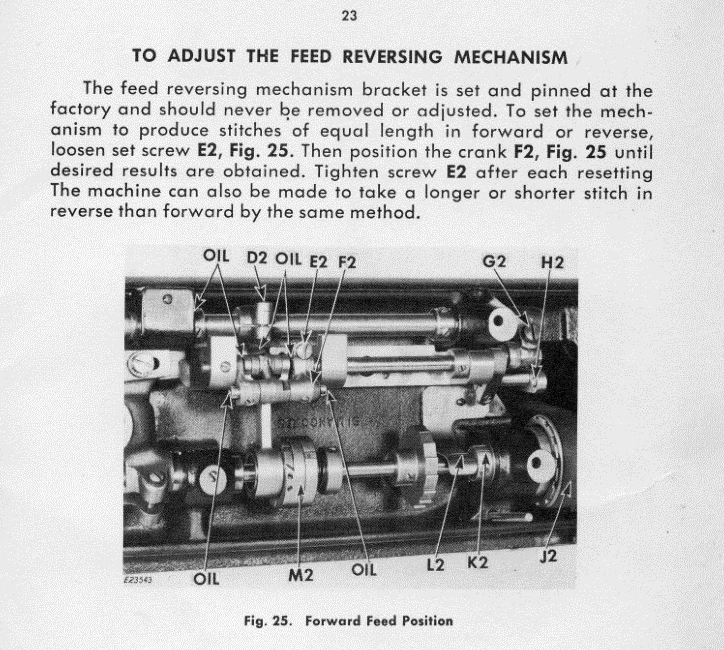

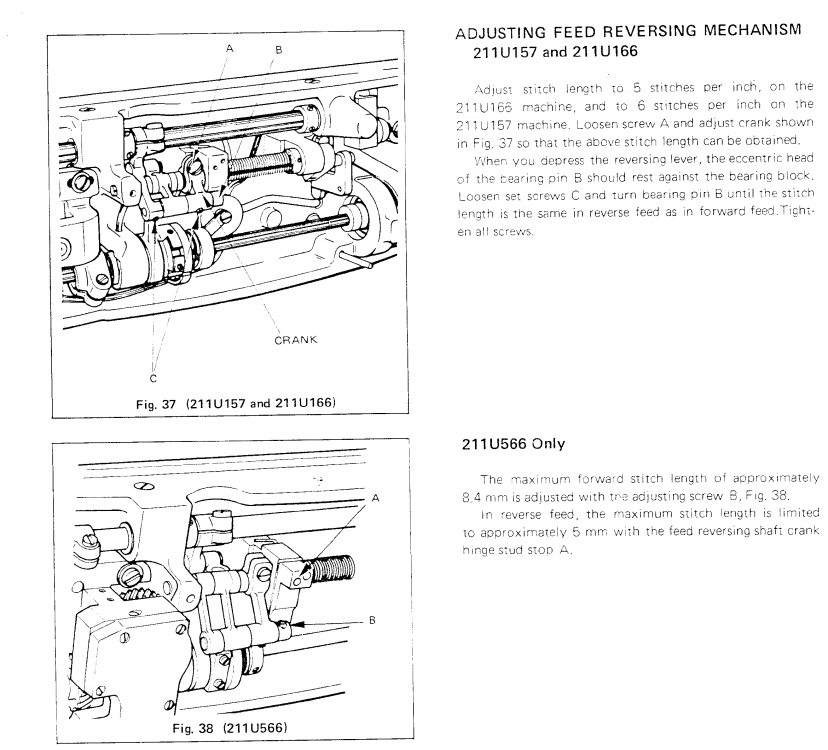

211U566 forward / reverse balance

Constabulary replied to vblouindemers's topic in Leather Sewing Machines

I just looked at the 211U566 Manual and the procedure should be pretty much the same as on the 211G166 and other 111 / 211 Singer machines. This is from a 111G156 manual and is maybe a bit more obvious - mechanism is technically the same but just slightly different cause the 211 seems to have a long spring on the rod right side of the crank or so. To me the difference are just the screws you have to loosen for adjusting the stitch length on the 211U566 the rest should be the same - thats at least how I understand it. Or do I get it wrong? This ifs from the 211U manual: -

Adler 167 - Timing Belt Replacement

Constabulary replied to Constabulary's topic in Leather Sewing Machines

he, he, he - thats good! So you understand why I´m kinda Singer crazy, right? -

Adler 167 - Timing Belt Replacement

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Michiel, you would not believe how much simpler this is on a Singer 111 - guess how I know -

Adler 167 - Timing Belt Replacement

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Excellent addition! Thanks for posting this! -

This is a very early Model 29 - not 29K the number is the serial number. You can check the date here: http://ismacs.net/singer_sewing_machine_company/serial-numbers/singer-no-prefix-serial-numbers.html Looks like 1893 made

-

you can also buy the slide piece new - from my experience they all have the same diameter - then its safe that the thread lever adjuster thread will fit. https://www.college-sewing.co.uk/82231-piston-joint-singer-29k-71.html

-

Check the manual, I´m sure it describes the function of the adjuster better than I could explain. However - very early 29 patchers came entirely without the lever adjuster and being honest I tried this adjuster (mine is different one but still) a few times and I have never ever noticed a significant difference in stitches or the position of thread knots - really - never! I only alter the top thread tension and that's it. It may depends on the material (thickens & density) you sew. That does not mean it is useless but honestly yet I haven´t noticed any difference. Other may have different experiences but this is mine. But when ever you will sell this machine - and this day will come - you still have an incomplete machine and a "knowing buyer" will notice this. So I would try to find this part just to have a complete machine.

-

is it probably because you are using a too small needle size - I´d try to go up 1 or 2 needle sizes. Edited 8 hours ago by Constabulary Forget this - I got you wrong

-

The above J & R is a maybe 100+ yrs old domestic sewing machine - not a leather sewing machine. Be careful - a Union Lock Stitch is not the same as a Union Special that is making a lock stitch! Also - "industrial" does not mean a thing when the seller does not know what he is talking about. You (as a potential buyer) should know better than a seller what you really need. Do not rely on what others are writing in their adverts or ebay listings. It´s better to know better - if you know what I mean. Start reading this thread - you will learn a lot about sewing machines:

-

I basically have restored all my sewing machines and if I would be a purist I would probably have a pile of cast iron but not many working sewing machines. You either buy what works / is available or you wait until you find a 2nd or 3rd machine to get together all the OEM parts. But yes, when ever possible I try to replace the "cheap parts" with OEM parts but that's not always possible. My 1st priority is that the machine is sewing the way I need it and then on the long view I try to find OEM parts (often enough randomly). I even have thrown out original parts and install foreign parts until the machine suits my needs (f.i. a needle bar just because I want to use a different needle system). Then OEM has no priority instead functionality is what counts. So it depends! But 1st priority is always that the machine does what I want - sewing! is it probably because you are using a too small needle size - I´d try to go up 1 or 2 needle sizes.

-

Have you tried to move the needle holder a bit closer to the hook? Also check the paddle shaped spring on the needle bar, sometimes they wear out and have a grove on the inside. When the leather is pulled up with the needle you need more foot pressure. What needle size and thread size are you using? Maybe you can try 135x16 needles because they have a scarf and can be set a bit closer to the hook. I`m also using 135x17 / 135x16 needle in my 29K71. Just what came to my mind... Please post pictures of your machine so maybe we can see something "unusual".