-

Posts

5,809 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

i do not see a reverse lever. Be careful with these old QUICK or EFKA Motors - they great when running but a pain when they stop working. They are no longer supported AFAIK and if you can get support it may be very expensive. Also make sure the motor runs on the voltage you have at home. It is wheel feed machine for shoe uppers so make sure you can adjust the stitch length you need for your products. A lot of wheel feed machines have a rather short stitch length like 2 - 3.5mm. Honestly - I would not buy it if you don´t want to sew shoe uppers.

-

Adler 104 stitch length - adjustment manual

Constabulary replied to Pterytus's topic in Leather Sewing Machines

And how often do you really change the stitch length? Sure - depends on the project, how many items you sew and so forth.... but most folks I think will sew at 5-6mm stitch length on heavy machines like this. -

I can see the roller foot flipped aside but cannot tell from the pic if it has a double needle but when I look at the Pfaff website the latest 1243 is a single needle machine with roller foot.

-

Adler 104 stitch length - adjustment manual

Constabulary replied to Pterytus's topic in Leather Sewing Machines

The 104 / 105 came with 3 (three) different stitch length levers so maybe they changed them for a reason. The last one is the simplest and close to what they have used on the class 4 model. Maybe your SLL has been replaced once... Let me see if I have pictures... EDIT: So I would guess they "simplified" the SLL for a reason. But I only can guess... I think in a time line yours is the middle model. The latest model has 2 limiters - just as the class 4 and you have to adjust F & R manually for either direction by setting the limiters. So if you are "good with metal" you can probably reproduce the latest model SLL and solve the problem that way. You know what I mean? Could work but again I only can guess - just my 2 cents. -

Singer Treddle Pressure Foot Marks

Constabulary replied to Rbarleatherworks's topic in Leather Sewing Machines

Well patchers have teeth on their presser feet because thats the way they feed the material. If you had a vintage 45K you would have feed dog marks as well but on the underside. The presser foot is kind of feed dog but on the top side. I would first try to reduce the foot pressure as far as possible. You can try a piece shrink hose on the foot but the machine will probably no longer feed the material as good as before. There once was a guy here who coated the foot with diamond dust or the like (do not recall what it was) if I recall correctly that worked well for him. Let me check if I can find this old post.... EDIT: found it -

Nothing wrong with going public - generally - but when I have issues with a 3 month old car or TV or lawnmower or what ever the 1st thing I´d do is to contact my dealer before I go public. And Toledo (he mentioned them) really has a great reputation so that would be my 1st way. Pretty sure they are real life people For sure there are "certain dealers" or should I say sellers who prefer making a buck instead of giving you support for your recently bought machine. But I doubt any of the Cowboy dealers would go that way. Anyway - MedusaOblongata I hope you don´t feel offended, if so - I´m sorry but IMO the dealer should have the 1st chance to make it right or give you support one or the other way.

-

Pfaff 335, Adler 69 type Cylinder arm caps.

Constabulary replied to RockyAussie's topic in 3D Printers and Lasers

Have I ever mentioned that I hate people who can print out this cool stuff You guys are awesome, I don´t think I had the patient for that! Looking forward to seeing more of this stuff. Printing old Singer sewing devices could become a business idea - probably. -

I always wonder why people go public with their issues instead of contacting the dealer they bought from. Anyway, to me it looks like your V-Belts are too tight and sound may come from the speed reducer. Look at your motor it seems to be in an angle probably because of overtightened V-Belt? I would loosen or remove the V-Belts an check all involved parts (motor, SR, machine head) individually

-

Parts list - also from CHIKON: Part List-441.pdf

-

does the bracket snap on the foot (somehow) for covering the teeth? I´m always wondering why so many sewing machine dealer (not all of course) do not care about the manual. It maybe take a few hour do make a proper one but that guarantees your customers will be happier. However - you can download a lot of 441 Manuals here and there. I once downloaded one on the CHIKON website which is pretty good. Instructions-441.pdf

-

Pfaff 335, Adler 69 type Cylinder arm caps.

Constabulary replied to RockyAussie's topic in 3D Printers and Lasers

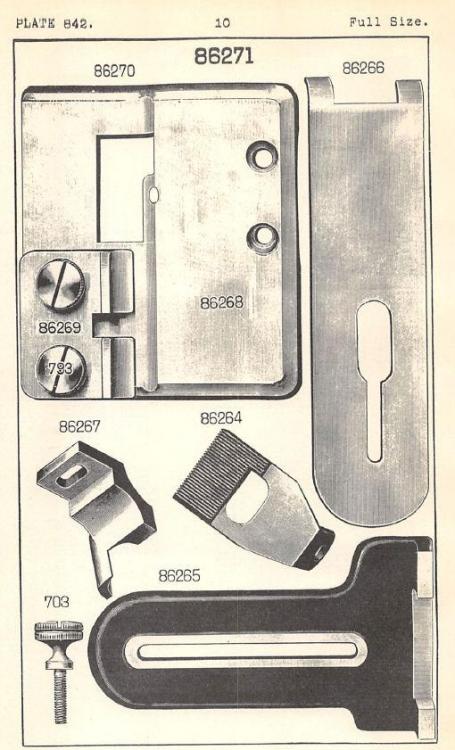

Ouuuuh Jimi, you have some interesting files on your C Drive **kidding** I think this is the device / set Jimi refers to. I wonder where all the nice sewing devices Singer once sold went to - you never find them. Are they all worn out and junked? Or still in use? Or is there a black hole for Singer parts? You even barely find presser feet for 45K´s -

Singer 111W - nice find - looks like a triple feed / walking foot machine! Could be that the timing belt is brittle...

-

Adler 104 stitch length - adjustment manual

Constabulary replied to Pterytus's topic in Leather Sewing Machines

How much difference is it between F & R? Is the difference in all lever positions or just in the longest stitch length? -

PFAFF 335, PFAFF 337 difference

Constabulary replied to DanishMan's topic in Leather Sewing Machines

some pictures may help to ID the technical features. -

PFAFF 335, PFAFF 337 difference

Constabulary replied to DanishMan's topic in Leather Sewing Machines

Look at the current models on the Pfaff website - seems the 337 has no needle feed, just top and bottom feed. There once was a Pfaff 337 for hat makers but that machine was a cylinder arm version of the Pfaff 130 domestic machine - kind of. I don´t think you mean this model, right -

Adler 104 stitch length - adjustment manual

Constabulary replied to Pterytus's topic in Leather Sewing Machines

BTW - the check spring is hanging loose, it should rest on the pin sticking out of the oval hole near the lower tension unit -

Adler 104 stitch length - adjustment manual

Constabulary replied to Pterytus's topic in Leather Sewing Machines

Haven't done this on a 104 but I would guess you can equalize the F & R stitch length by repositioning the feed eccentric on the top shaft. However unequal wear on the stitch length scale plate or the wedge piece on the stitch length lever which touching the scale plate may cause uneven stitch length as well. But I can´t tell the condition from this picture. Or - just a guess - have you tried to turn the wedge piece on the stitch length lever by 180°? You never know... -

Excellent machines - you will love it! I really loved mine too but I had no work for it so I have sold it with a tear in my eye. And it is really a beast and it took a lot of space. I put it on heavy casters because and I needed it moveable due to space issues.

-

Adler 104 stitch length - adjustment manual

Constabulary replied to Pterytus's topic in Leather Sewing Machines

Adler 104 / 105 came with different stitch length adjuster levers. I guess you have the early one (pretty similar to Pfaff 145 but larger)? Please post pictures of your machine. -

Pearson no 6 help with sewing thread

Constabulary replied to youdesiremenow's topic in Leather Sewing Machines

Sounds not like a machine issue - rather poor thread I guess. Best you can do is using linen thread (maybe even pre-waxed) on this machine. I also used polyester/cotton thread (not bonded) with no issues (have sold my machine this summer). -

I´d say check with college sewing - they usually respond fast - make a video and send them a link

-

Your bags? Looks like you killed at least one WWII era USMC Poncho and an .30 M-1919 BMG ammo cloth belt for it... I can see some parachute hardware too...

-

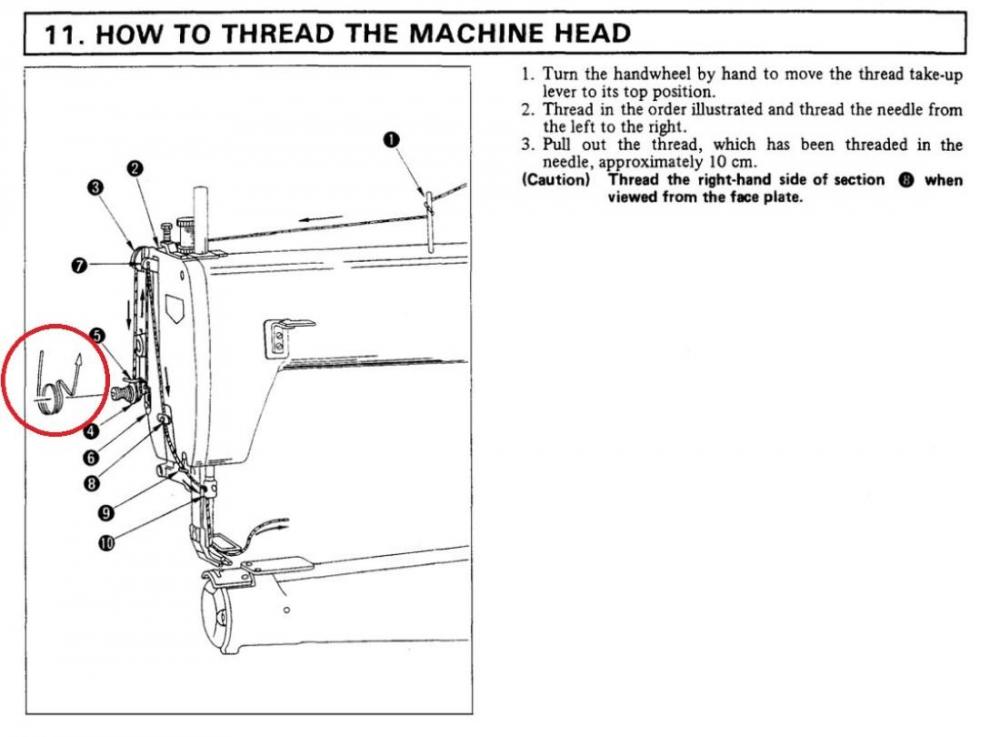

I have no 4500 but the 45K / 45D have technically the same top tension assy - so I tried 1 1/2 and 1/2 wrap. 1/2 wrap means I just let the thread "touch" the bottom side of the tension wheel (small pulley) in the tension unit and 1 1/2 means I add a full wrap around the tension wheel. When I do 1 1/2 wraps (Singer manuals calls this: "once completely around the tension wheel") the needle is pulled to the left by the thread. I never tried 2 full wraps and I see no reason why I should do this. However - it may depend on how much tension you put on the upper and lower tension unit (the one with the pulley). I usually have a very low tension on the lower unit the way that the tension wheel (pulley) still spins while feeding the thread. And I adust my top tension only in the upper tension unit whereas Singer manuals says adjust tension on the lower unit and when tread slips on the tension wheel add tension on the upper unit... So - many ways lead to Rome - I figured the way I dot it works quite well for me. EDIT: out of curiosity I checked a 441 manual and it shows a 1 1/2 wrap.

-

You are right, it´s that simple and as so often in life - size matters. The size of the needle hole in the feed dog or needle plate and the needle to hook distance and the gap between needle plate notch and the small tongue on the bobbin case (or positioning finger at the Pfaff 138) have an influence on the thread thickness you can use. This is often overlooked and people think they would need a different machine or different subclass to run thicker thread. You can achieve a lot by adjusting the hook saddle. Moving it a bit to the right makes the gap between NP notch and bobbin case tongue a bit larger and therefore thicker thread can slip through. When machines have a horizontal hook (like Pfaff 138) they usually have a positioning finger that holds the hook in position and the finger can be adjusted back and forth to allow a thicker or thinner thread. This is trial and error and there is no rule of thumb of how thick the max thread can be. It depends on the original setting and of course every adjustment has its limits. But most important is the needle hole. If the hole is too small for the needle further adjustments make no sense.

- 26 replies

-

- thread size

- sewing machine

-

(and 1 more)

Tagged with:

-

(first post) Used Sewing machines

Constabulary replied to Donkeykong's topic in Leather Sewing Machines

Geo blocking! They have blocked IP´s from certain countries. I only can see the website by using VPN or TOR. Well these machines do no look very promising. They look like written off machines from a sewing plant. I guess most of them are sold for parts. Do not expect any support from them.