-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Which machines are worth keeping

Constabulary replied to oyvindbl's topic in Leather Sewing Machines

I´d agree keep em all if you have the space. I´m pretty sure your mom would be proud of you when she sees all the machines alive again! Set them up, make em all work and then you can decide. But at one point you probably will regret selling one or another machine. Other people trying to "scratch" together certain machines over a long period and you are in the fortunate position of already owning quite lot of machines - if you know wat I mean. -

hm - you already bought the machine (even from a dealer) and you did that for a reason. So what recommendations or warnings are you expecting?

-

Pfaff 145 needle and/or foot not lining up

Constabulary replied to 24602's topic in Leather Sewing Machines

I´d open the face plate and check if the guide for the needle bar rocking frame is properly positioned and if the pivot pin and NB rocking frame are all the way to the right. -

Pfaff 545 Linkage for lifter?

Constabulary replied to Pintodeluxe's topic in Leather Sewing Machines

Pfaff models often share parts just as Singer and Adler. However - you never know so comparing the number is important. But I have no Pfaff parts list I could check - sorry! The lever I have linked was just something I have found while looking for other parts and it at least looks very close. I sometimes just check this sellers listing as he often has interesting parts. Paypal should not be an issue - just buy it and pay the currency conversion usually is automated in the payment process. -

Don´t know what parts diagram you have but this one is the best you can find - very clear and detailed. Download: Singer 29K71 29K72 29K73 Manual and Parts List

-

Pfaff 545 Linkage for lifter?

Constabulary replied to Pintodeluxe's topic in Leather Sewing Machines

https://www.ebay.de/itm/Pfaff-141-Umlenkung-Kniehebel-8328/293287710957 But check with the seller first reg. parts number. Also check his other listings, he has a lot of used spare parts. Maybe worth buying some more parts. -

I will set up my Singer 51w with a short table as well and will use a short flat bed machine (107w / 143w) in the same table - one day. So before you pull the trigger on this table make sure the cut out fits for your machine and the hinge points line up. IMO the small tray on the right is kinda space wasting on the left (if that matters) So maybe a DIY table top + a standard table that you cut down (center bars) could be an option too. Just my thoughts

-

Singer 111w155 or Singer 111w154

Constabulary replied to Don Ayres's topic in Leather Sewing Machines

Hope this brochure helps But you never know if a vintage machine has been modified once... Singer 111w Class Machine Brochure.PDF -

Just wondering - is there no international help for fighting the fires in Australia? I know A is in the middle of the pacific but still... Maybe Japan or South Korea? For sure a challenge to bring in water bombers but come on.... really no one? At least I have not here of any international help. EDIT: Just figured that Canada sent 21 Firemen - not much intl. help though.

-

Piping/cording foot for my Durkopp 239

Constabulary replied to toxo's topic in Leather Sewing Machines

Singer 111 feet should work. They at least work the other way around I have some Durkopp feet for my Singer 111. -

I only have an outside view and don´t know what kind of arrangement you have with the dealer but I somehow would be kinda pissed when I read about all the issues and lesser foot lift an d stuff - even at the lower / fair price you paid. Do you updated the dealer with the issues you have? Again - just my outside view...

-

I used M5 screws on my former Singer 111 but you may need an additional bracket for mounting the drop down guide. I have used KB09 from college sewing: https://www.college-sewing.co.uk/accessories/sewing-guides/sewing-guide-brackets This was on my former 111G156 which is quite close to your 239 So before you drill holes in the machine body make sure the drop down guide or its bracket is not disturbing your foot lift lever or is disturbing you somehow different. On my current 111 I have no drop down guide as I figured I barely need it for my work or it was disturbing me. But that of corse depends on your work. EDIT: Another thread reg. drop down guides:

-

Why is the feed dog timing like this?

Constabulary replied to Gymnast's topic in Leather Sewing Machines

Really? Once again domestic sewing machine sciences? -

ouh - sorry for that kind of machine I have no timing values... But when do a google search with "Timing Chinese Patcher site:leatherworker.net/forum" something may pop up. EDIT: This guy has some videos reg. the Chinese patcher - maybe helpful for you: https://www.youtube.com/user/BareHerbalBubbles/videos

-

What machine are you using? Most likely needle hook timing is off or needle bar is to high or too low.

-

Adler 30-1 treadle long arm patcher purchase questions

Constabulary replied to chiefjason's topic in Leather Sewing Machines

The 30-1 is a patcher machine with top feed only (no needle feed) and it leaves marks of top side of the leather because the machine is feeding material with a sharp toothed presser foot. These patcher machines are not really production machines they are basically meant for repairing things like shoes, bag, pouches, sewing on patches on blankets and other things and so forth but they are not really meant for sewing gun holsters. Patchers usually just have a max. stitch length of 5mm (and often patcher do not reach this due to worn parts) and stitches become shorter the thicker the material gets. Actually some machines can handle 207 thread but usually they max out at 138 furthermore the 30-1 has an extremely tiny bobbin and it holds just a few meters of thread. Do a quick google search and you find a lot of topics on LW.net regarding the Adler 30-1 machines https://www.google.com/search?q=Adler+30-1+site%3Aleatherworker.net%2Fforum&ie=utf-8&oe=utf-8 If you still want a patcher machine better look for a 30-7 (higher foot lift and larger bobbin) or similar patcher with large bobbins. -

Question about the Techsew 5100 SE

Constabulary replied to Bransen111's topic in Leather Sewing Machines

If you can (financially) keep them both! f you have space problems alter one machine stand the way that you can switch the machine heads. That would safe you a lot of space. -

I´m not sure what M60 really is - is it like TKT 60?

-

Since it is your son in law just go ahead and test the machine. This is a very comfortable buying situation! Pretty sure it will suit your needs. Download a manual - read it - test the machine. Pretty sure you will be please but as always - used machines may need some TLC / adjustment / oiling here and there especially when it was in storage for a long time. BTW 10oz total thickness or multiple layers?

-

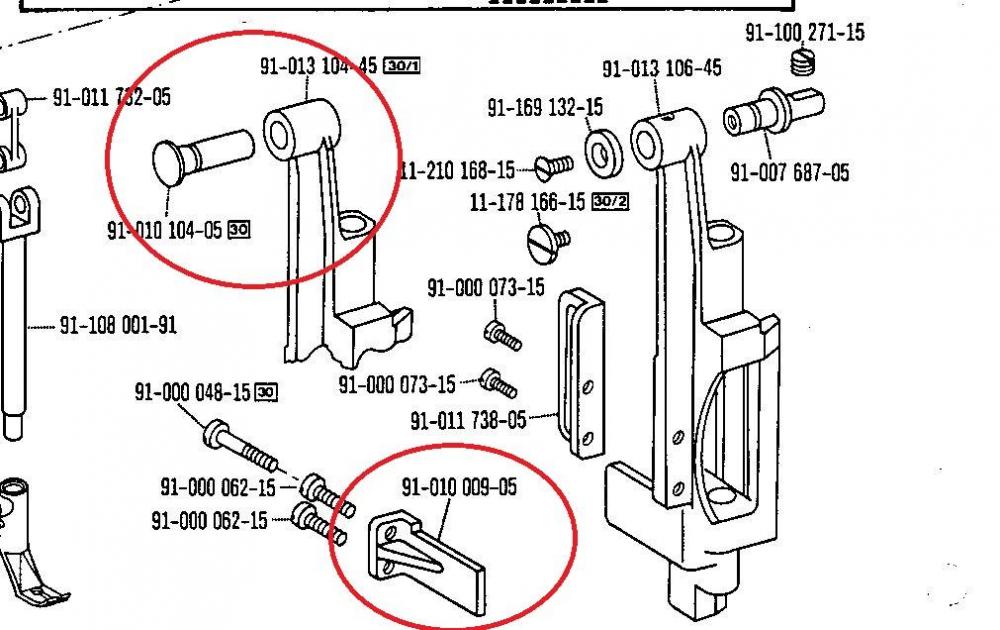

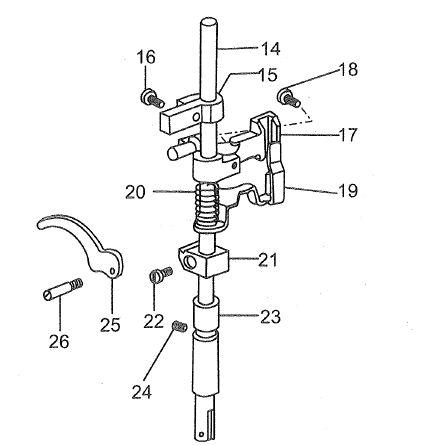

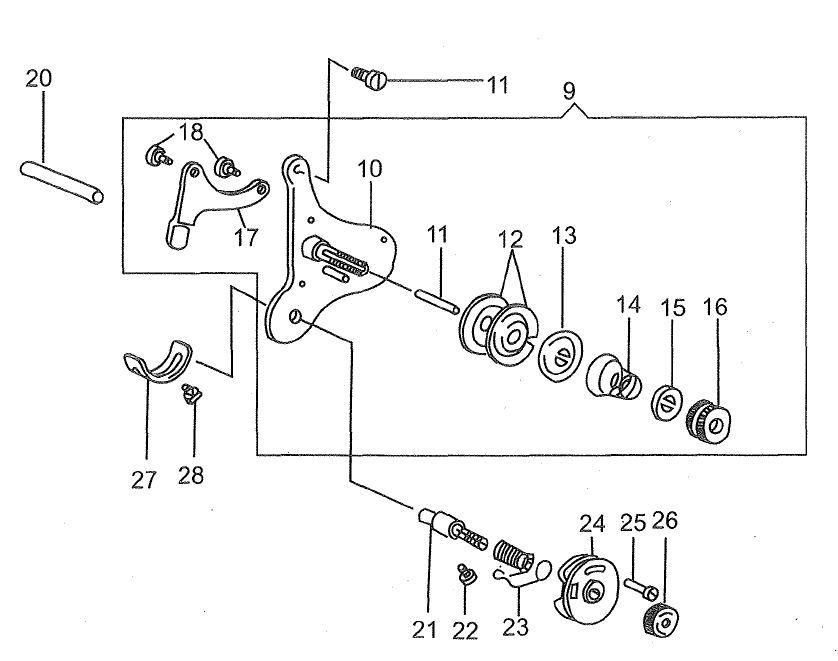

so maybe these two drawings help you to understand how the tension release works - it´s from a Singer based machine bit the 239 has very similar parts #19 (Dwg. 1) is the tension release slide (If I recall correctly you replaced it once, don´t you?). When you lift the foot lift lever it pushes against #20 (Dwg. II - this pin goes back to front through the machine head) and this pin is pushing against #17 which is pushing against the small pin # 11 (which is inside the threaded stud) and this small pin is finally releasing the tension when it is pushing against the disc #13. So I guess for what ever reason the tension release #19 slide is (probably) too low and does not reach pin #20. Or the small pin #11 is too short and does not reach the center bar of the dics #13. Or - the center bar on the disc #13 is missing or worn. You probably can slightly adjust the center bar on disc #13 (gently hammering it toward the small pin) or you DIY a new small pin from a bicycle spoke or a drill bit or what ever you have. Maybe just 0.5 mm - 1mm are missing - that's already enough for not heaving a tension release. All a guess w/o sitting in front of your machine. EDIT: or - loosen screw #22 and push the whole tension unit toward the machine body and then tighten #22 again (of course) - maybe it helps .

-

Is it probably because you have no proper top tension release? When you have fully lift the foot lift lever and the thread take up lever is in upper position check if the two tension discs are free or if they are still under pressure of the spring.

-

If you need a manual the 29K72 is almost identical to the 29K60 - just minor differences. Hopes this helps: Singer 29K71, 29K72, 29K73.pdf

-

I´m not sure but the stitch length in relation to the fairly large needle holes looks very short so it its kind of perforating the leather and that weakens it - or not? Are you using a leather tip needle or round point needle? Just my thoughts...