-

Posts

5,809 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Is it probably because you have no proper top tension release? When you have fully lift the foot lift lever and the thread take up lever is in upper position check if the two tension discs are free or if they are still under pressure of the spring.

-

If you need a manual the 29K72 is almost identical to the 29K60 - just minor differences. Hopes this helps: Singer 29K71, 29K72, 29K73.pdf

-

I´m not sure but the stitch length in relation to the fairly large needle holes looks very short so it its kind of perforating the leather and that weakens it - or not? Are you using a leather tip needle or round point needle? Just my thoughts...

-

It´s because of worn parts - the bell crank lever (the part with the stitch length numbers on it ) has a major influence on the stitch length. It´s likely the tip is worn down. The feed motion ring has an influence as well but you barely can tell if it is worn or not. So first thing I´d replace it the bell crank lever. Don´t know what part supplier you have in Canada but the parts number is 82167. You should find this part almost everywhere - even on Ebay. Also make sure the stitch length adjuster is correctly assembled. The squared frame and the gib have a "wedge" which have to be positioned correctly. The wedges give the presser foot bar space for its movement (feeding).

-

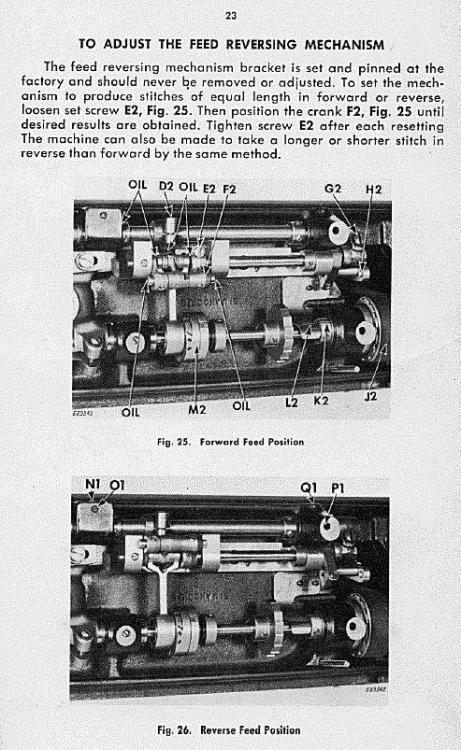

Funny to read my own 6 years old posts - I have learned a lot since then My 111G156 has a 12mm foot lift and can sew what fits under the feet but depends on density of the material. The 111G156 has 5SPI when you have equalized F & R stitch length but you can alter that to a longer F stich length but when you do that the R stitches become shorter. The procedure is mentioned in the manual.

-

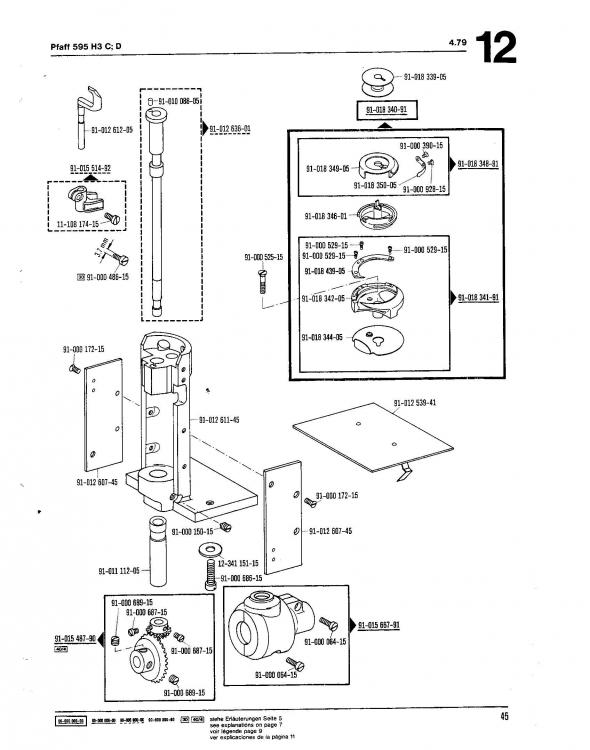

instruction manual - no service manual, sorry! Maybe this pictures gives you an idea - its from a 595 parts list and it should pretty much the same as on your machine I think.

-

I haven an english language Pfaff 141-5 Manual. The head part is the same as on you 191 (permanent wheel feed + roller foot), the bed section is of course different. The file size is to big to attach here so when you send me your email address by PM I can forward the PDF to you. Maybe that helps you. You only say "that needs timing" so what particular problem do you haven or what problem is not covered in the other manuals. What screw do you mean? Please post pictures (not too small please).

-

jack Jack 513A engine problem...

Constabulary replied to FREDERIKDIAMOND's topic in Leather Sewing Machines

Just to put it straight - it was the black lever? -

You may have seen this. Pretty sure this would work on a Cobra as well but check with the dealers: However to me it looks a bit odd too me. I´m guessing they are running too thick leather in their binding attachment. And therefore the stitches are shorter than the binder attachment travel. When you run too thick binding material through your binder the synchronized binder bracket pulls back the binding material and stitches become shorter because of the friction between binder and binding material - guess how I know (had the same problem with my 108w20). EDIT: Just noticed this Video has been posted by Uwe before

- 34 replies

-

- sewing machine

- binding

-

(and 1 more)

Tagged with:

-

Who is an European supplier of heavy beehive springs?

Constabulary replied to Gymnast's topic in Leather Sewing Machines

BTW - I may have a heavier spring as well if shipping at college sewing is toooo expensive - let me know. I have approx 15+ beehive springs in all kind of strengths, lengths, diameters... But I have to check how much shipping to DK would be. -

Who is an European supplier of heavy beehive springs?

Constabulary replied to Gymnast's topic in Leather Sewing Machines

Like this? https://www.college-sewing.co.uk/b3114-232-000-beehive-spring-heavy-juki-genuine.html -

MAKING PARTS FOR OUR TOOLS... JUKI 441 LIFT HANDLE EXTENSION

Constabulary replied to Louiesdad's topic in Leather Tools

LW member UWE once sold similar ones but seems to be out of stock atm. His version did not come in contact with drop down guide. https://uwe.store/products/ux441-manual-foot-lift-extension-lever -

Not sure what you mean with moving the needle... Loops on top or bottom is usually a tension problem or you have a problem with your thread path or parts that put tension to the thread. Can you post some pictures of your machine and how you have threaded the machine? I´d also check the paddle shaped check spring on the needle bar if it is worn (grove of inside of the paddle end). Guessing you already have a manual, if not I attach one here. Manual Singer 29K62.pdf

-

You have to post pictures for identifying the machine.

-

2nd what Wiz said! Are you using a knee lifter or foot pedal for lifting the presser foot and you probably have the foot on the pedal or you are pushing the knee against the knee lift lever ever so slightly? If so this could cause a permanent top tension release and you get a "bird nest" on the bottom side of the material.

-

Adler 104 stitch length - adjustment manual

Constabulary replied to Pterytus's topic in Leather Sewing Machines

Very nice! Still wondering what the "original issue" was - or is. Anyway - as long as it works for you this way its a good solution. Well done! -

jack Jack 513A engine problem...

Constabulary replied to FREDERIKDIAMOND's topic in Leather Sewing Machines

I think with speed governor you mean what I called accelerator unit - the small squared box with the white plastic lid and the small lever on the outside. When you open it (3 screws) you see a small black lever and I think it is too far away from the hall sensor - the small black thingy with 3 poles which is soldered on a small green board. You probably have to play with the position of this black lever. -

This (to my best knowledge) is a SEIKO built but Singer branded "clone" of the Seiko CW-8B-2 which also is similar to the Consew 227R-2 . The mother of all mentioned models is the Singer 153w but this machine has no reverse. So when you look up Consew 227R-2 and Seiko CW-8B-2 you will find lot os information.

-

Adler 104 stitch length - adjustment manual

Constabulary replied to Pterytus's topic in Leather Sewing Machines

Definitely better - now I get it. So what you need is a curved center piece from the flux capacitor, I think. Flux capacitor parts are universal fit and solve everything. Sorry can´t really help much more here. My way would be the angle bracket with 2 limiters like they have used on the later 104´s. Thtas probably something even a later buyer will understand (one day you will / have to sell it) instead of riddling what this "odd shaped / non standard" piece is. And when it is worn (if printed out of plastic materials it will be worn sooner or later) he will be screwed. Keep things simple! My 2 cents. -

Best walking foot sewing machine for thread size 138

Constabulary replied to siddiqui2008's topic in Leather Sewing Machines

ouh - thats kinda cool! I once made something similar from some old drawers but for a different purpose - not for a portable machine but as an "on top adapter" for my Singer 111G156 table because the 212 flat bed is longer and I dont want an extra table for the 212. -

Adler 104 stitch length - adjustment manual

Constabulary replied to Pterytus's topic in Leather Sewing Machines

a mad scientist you are Reminds me of curve sketching and things - didn´t like it as well as stochastic (I get goose pimples ) -

jack Jack 513A engine problem...

Constabulary replied to FREDERIKDIAMOND's topic in Leather Sewing Machines

W/o knowing details, so I guess you set the speed correctly (don`t know - video is too fuzzy and is not playing well on my end). So I would guess in the accelerator unit the lever with the magnet is not properly set. I guess it is too far back (away from the hall sensor). I guess you have to move it towards the hall sensor a little bit. I only can guess... so I would recommend contacting College Sewing or the dealer you bought the motor from. -

You find a lot of good videos from Solar Leather, Neels Saddlery or LW Member UWE and others for making adjustments on the 441 type machines. F.I. check the Solar Leather website - this probably is the best support website in terms of sewing machine I ever came across - and (for me) one of the best arranged sewing machine dealer website AT ALL (all very clear and lots of information) : http://www.solar-leather.com/supporthelp Maybe you find what you need for solving your future problems. Even when you do not own one of their machines its worth watching the videos - really!

-

aaaah... not really sure what you want to say... Break to get a pictures up - years old - girl in dora socks? Is this like: I spy, with my little eye

-

yes - its a German machine - everything is bigger here Even the idiots