-

Posts

5,806 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Can any help identify this machine?

Constabulary replied to drc9723's topic in Leather Sewing Machines

I cannot ID is but it is not a Singer but class wise I´d day its about class of a Singer 16k, 31k or 96k - so rather a garment sewing machine or light upholstery sewing machine. -

How about Germany: https://www.ds-leder.de/fiebings-oil-dye-946ml_fiebing-oil-dye-946ml-koenigsblau.html http://www.lederhaus.de/lederfarben/lederfarbe-fiebings-pro-oil-dye.php https://www.rickert-werkzeug.de/de/Farbe-Pflege-Kleber/Farbe-Zubehoer/Lederfarbe/Fiebing-s-Pro-Dye-Prof.-Oil-Dye.html Rickert is quite fast.

-

Messed up my machine (juki 441 clone), advice appreciated.

Constabulary replied to Ysalex's topic in Leather Sewing Machines

Looks like a set screw. I guess it is hardened. If I were you, I´d try to drill it out entirely with a carbide drill bit and cut a wider thread. Or try a diamond tip tile drill. But that's probably not everyone's cup of tea EDIT: just to give you an idea what a tile drill (or hole saw) can do: -

not sure if it helps but there is a video showing a problem with the Pfaff 138 F & R stitch length. The stitch length levers are all the same on the Pffaf afaik, so maybe worth checking.

-

Pfaff 345 not picking up stitches

Constabulary replied to paukenman's topic in Leather Sewing Machines

This may help you: Pfaff 345 Service Manual.pdf -

Can any help identify this machine?

Constabulary replied to drc9723's topic in Leather Sewing Machines

ask for more pictures - should be no problem for the seller. -

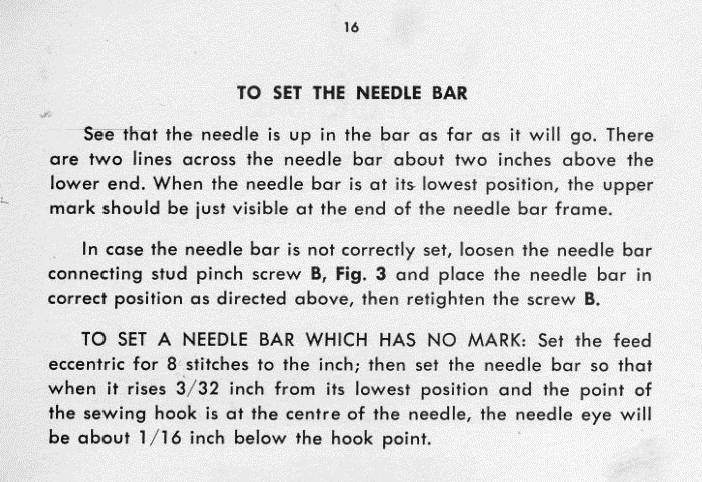

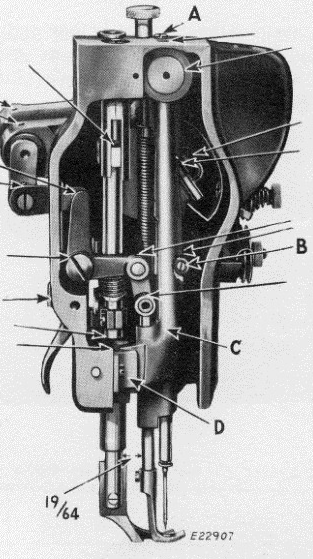

If it was my machine I´d adjust the needle bar height to accommodate the standard 135x17 needle. The longer the needle is the thicker material you can sew. Its just raising / adjusting the needle bar as as mentioned in the manual. Its a quite easy task. Just one screw you have to loosen.

-

I heard of such people - crazy folks

-

Metro Spezial 9346 Patcher What Subclass?

Constabulary replied to JJN's topic in Leather Sewing Machines

# 20 bobbins are approx 15.5mm x 8.5mm +/- # 30 bobbins are approx 17.5mm x 10mm +/- the #30 hooks have a small bar across the bobbin - see picture EDIT: Hope I haven't mixed up something... -

Metro Spezial 9346 Patcher What Subclass?

Constabulary replied to JJN's topic in Leather Sewing Machines

I´m almost certain that is it not a 30. if it was a 30 the black gear box would look beefier. I guess it is a 20. Whats den diameter of the bobbins? Length of the needle is also a hint - only the 30 uses the system 88 needle, the 10 + 20 are using system 81 needles. System 88 is 55mm long in total System 81 is shorter. -

I have seen this ID plate a few times already. This is a machine from the early 1900´s

-

Really? Two 2 second videos? Ask your self - is this sufficient for a technical diagnose from the distance? Even when I look at the videos twice... no way that I could tell a technical disorder from a 2 second video, 2nd video is even blurry. What does it mean? Skipping stitches? Have you checked the needle hook timing? Do you have a manual with timing values? Have you bought the machine from a dealer - then check with the dealer. You say you are "rather new" so better take it to a proper industrial sewing machine dealer instead of playing with the safety clutch.

-

looks like you are test sewing on 1 layer, I´d double the layer and try again.

-

I have carpal tunnel syndrome for almost 13 (+/-) years now - first I got cortisone shots in the wrists when it became toooo bad (at night) - that really worked well for me. Meanwhile I can live with it quite well (looong time no cort. shots). I feel when its getting worse and I quit hardworking for a few days and then its gone. Yet no surgery.

-

Yes, its mine - press and thingy. Its indeed an electrically heated hat shaper / spreader / stretcher from the 1930/1940´s

-

Agree - I just recently set a bunch of heavier copper rivets while replacing carrying straps on vintage plywood pack boards. No way that I could have done this with a hand press and I really have a quite heavy one - not the "Cheap Charley" ones from China. I had to swing the hammer quite a bit to mushroom the rivets. May work with a pneumatic, hydraulic or kick press but I don´t think it will work with a "plain" hand press.

-

You did not pay 200 for installing this tension unit - did you? It is pretty much is the same (if not the same) you find on 29K, Adler 30, singer 45K, GA5-1, Adler 4, 5 ,104, 105.... Tension springs may vary but they are rather cheap.

-

I probably got you wrong... That tension unit if for darning (requires and extra device) or sewing waxed or heavy thread, some are using it as guide when winding the bobbing (so do I). The new Adler 30 no longer have this tension unit. You can download a manual for the later Adler 30 here: http://www.bootmaker.com/adlernew.pdf This is a download link for a parts list: Adler 30 parts list

-

I don´t know what I see there but not matter what it is there is "something" that does not belong on this tension. On this threaded post belong 2 tension disc, a beehive spring and a nut, but nothing else. Just check other Adler 30 pictures. BTW - do you have a manual for your machine? Checking a manual is always a god idea.

-

post pictures please - not sure what you mean

-

Typical user questions: Are these small or large hook machines, can they handle 207 thread, how high is the foot lift, can I sew holsters with them, are they tripe feed or drop feed, where cam I find binders? I have problems with the top tension with my KL-504 can someone please help me? Really impressive - sewing technology obviously made a few huge steps in past years. KL-504 -> Transformers are a joke compare with this sewing... thingy. However - some of us still like the old clunkers and some of use for sure like to have all the electronic bells & whistles...

-

Dürkopp 18 Patcher Restoration - long journey...

Constabulary replied to Constabulary's topic in Leather Sewing Machines

Honesty - do you expect that a company like Schmetz / Groz-Beckert is "simply" making a small batch of just a few hundred needles with a slightly longer grove just for you? Really? As far as I know Schmetz is no longer producing needles in Germany and has been taken over by Groz-Beckert a few years ago. So I guess the majority of GB and Schmetz needles is coming from Overseas sources nowadays. I´m not sure if GB is still producing in Germany at all. A while ago I noticed that new Schmetz needle packs no longer have the imprint "MADE IN GERMANY" it now says "MADE BY SCHMETZ" - hmmmmm ... pretty sure that's for a reason. EDIT: The latest pack does not even say "MADE BY SCHMETZ" .... maybe for a reason - I don´t know. -

Holy Crap - thats the manual for the early 51w - the one I have Not exactly the same but for the early one... Nothing new in there but nice to have. THANK YOU SO MUCH!!!!

-

Dürkopp 18 Patcher Restoration - long journey...

Constabulary replied to Constabulary's topic in Leather Sewing Machines

It´s indeed challenging. Some websites show technical pictures of the most common needles. Finding technical information on vintage needles can be tough. Fortunately I have an old book where needles are pictured in original sizes. Not all needles are shown, just the most common of that time (Book is from the 1940´s I think)