-

Posts

5,803 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Constabulary

-

Claes bootpatcher user manual and needles

Constabulary replied to susanjeanscott's topic in Leather Sewing Machines

Needles should be system 88. Not sure which manual you have but this one (German Language) should be fairly close: Claes+Elastik+I+u+III_cleaned.pdf -

just figured I could be wrong with that - just found this thread regarding a 105-27 and it seems to have screws in this subclass. 😉

-

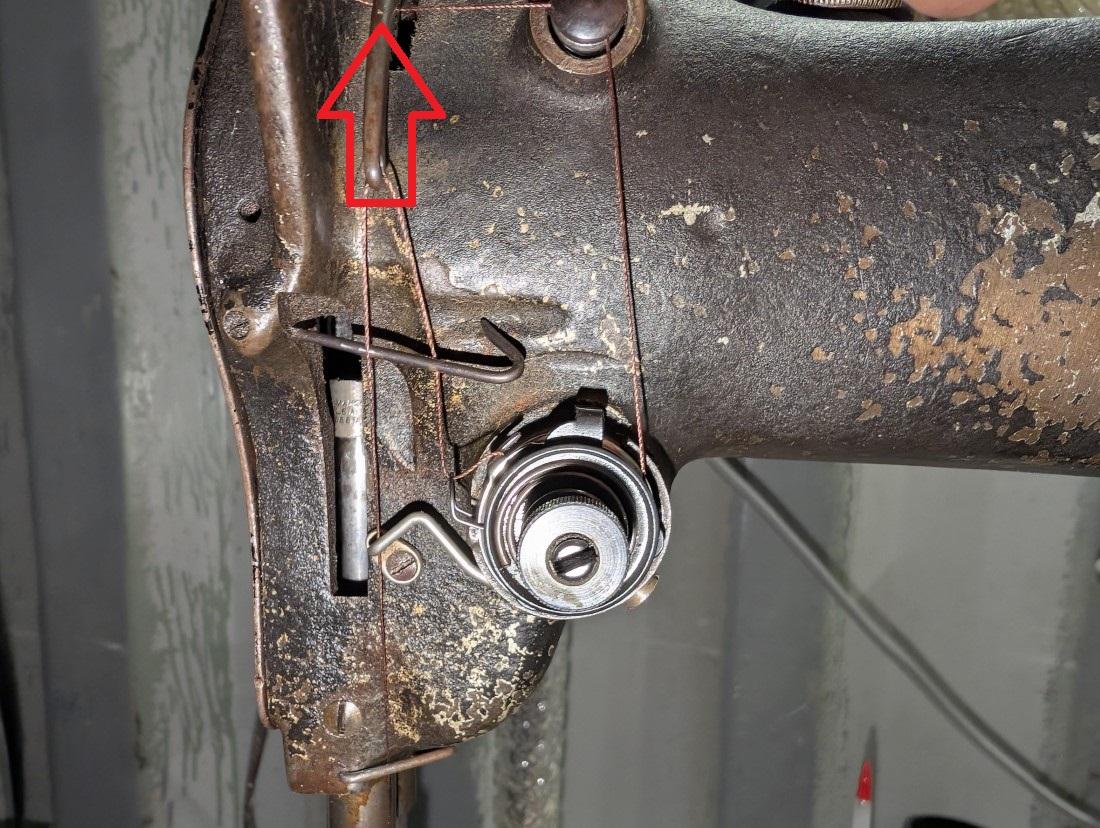

what I have noticed so far is: The needle plate / throat plate seems (!) to be modified and an the needle plate is missing material (or a deflector cover) left side of the roller foot / feed dog. Maybe this is something custom made but I can`t tell from the pictures. Not sure why this is but it is / looks unusual IMO. BTW - the original 105-27 came set up as jump foot machine and not with roller foot. So seems your machine has been modified quite a bit. But this could be custom made and I don´t want to judge this but it is not how the machine left the factory. In your video it seems (!) that 2 thread guides are missing, one on the needle holder (seems to be ground off somehow) and one on the face plate. Therefore the thread is "bouncing" around. This may affect the loop forming and that could cause thread breaking. EDIT I: Some one has modified the shuttle race as it seems. Your is held by 2 screws (maybe they are too tight???) but originally it has a U shaped sheet metal leaf spring that is holding the shuttle race in place. But again - could be a modification a customer asked for. Hard to tell w/o knowing the history of the machine. EDIT II: some pics of how the thread guides look on an Adler 104

-

singer 45k Singer 45K25 Roller Foot

Constabulary replied to nategines's topic in Leather Sewing Machines

just found a thread from 2024 regarding the Adler Roller Foot. https://leatherworker.net/forum/topic/120449-help-needed-_-cant-find-roller-foot-for-45k89/ Old parts number for the roller foot was 06422 - new parts number is 104220124 College sewing in UK had them (out of stock): https://www.college-sewing.co.uk/104220124-roller-foot-durkopp-genuine.html but sit down before you click the link 😉 (as I said before) Back in the days when my interest in sewing machines started I needed a slide plate for an Adler 104 flat bed machine and IIRC they asked 50€ + tax and shipping but that was w/o spring and and screws. That was just one "Adler parts situation" and soon I figured that certain Singer parts (and their clones like SEIKO f.i.) fit for certain Adler machines as well cause Adler back in the old days copied a lot of parts from Singer 45K´s 😉 That was the time when I discovered College Sewing in the UK and their wide range of Singer parts.... (and Seiko, JUKI.... who cloned Singer and so forth....) So guess why this guy from the land of Pfaff and Alder is so Singer crazy. It´s because of Parts Parts & Parts. But Brexit changed a lot but I´m still Singer crazy.... Still for the same reason. -

singer 45k Singer 45K25 Roller Foot

Constabulary replied to nategines's topic in Leather Sewing Machines

what Wiz said! The above linked roller foot will NOT WORK. But OEM Adler 4, 5, 104, 105 roller feet will work but they cost big $$ We had this topic before: -

Looks like a model from the 1980 which is slightly different to the latest model. IIRC the blade spring on the rear is a different one on the latest model but thats the only major difference I recall. Right now I have a very similar machine here and can take some pictures if you need assistance. Some time (years) ago I translated a 8346 mechanics manual from German to English for one of our members (seems I had a lot of spare time back then 😊) but I have to look for it in my records. I´ll send you a PM if I find it. BTW some of the parts I see in the pictures obviously do not belong to this machine. FI the Singer class 15 bobbins and the bobbin cases.

-

Very wide twin needle guage machines?

Constabulary replied to medion's topic in Leather Sewing Machines

be careful with very wide needle spaces and Singer 212 machines (& their clones - probably). I have a 212G141 and have it set up for 1/4" + 3/4" and wanted to use 1" as well BUT due to the width of the double needle holder it is necessary to alter / grind off some material from the casting to make room for the wider needle holder. I only can speak for the 212G1414 (using 135x16 needles) but the problem may be the same on other machines / brands as well. However in my case I´m using a split needle holder which is longer than the standard needle holder so it may depend on the machine and how you set it up. I just wanted to share my experience. 😉 This is what I did with my 212G141 some years ago -

I´m pretty sure there is a market depending on the price and the features of this motor. So asking potential customers for their needs is a good thing in general. Maybe there will be a line of motors with different features and therefore different prices. The range of leather workers is wide. Some have a deeper wallet than others and some have tools for installing motors and DIY building speed reducers that others don´t have (f.i. due to income or the space they have). So a slow start high torque and affordable plug and play motor is not a bad idea I think. Let them do their research and work at the end we will se what they are coming up with and we can decide if we need it or not. My 2 cents.

-

now that you mention jump foot I have a different view of that picture - makes more sense now. Cool machine - love it! 👍 I guess it is using the "common" singer hook as for 153w and so forth. The availability of parts for theses dead old machines always surprise me. Thats why I´m a sucker for vintage Singers. 😉

-

looks as if it had an edge trimming device? There is a bar with a blade, right?

-

Indeed W&W based. Singer took over W&W in 1905 IIRC and continued some of their models for a while. Looks like you can alter the needle space by moving the needle holders. Thats cool! I restored a 51w post bed machine with about the same upper

-

Rare model I guess, some pictures may help to figure more. But I assume it is based on a Wheeler & Wilson 12w maybe you can try it this way....

-

hard soldering then drill the hole and polish it but new take up levers are available new. Should be this one but check parts list first: https://www.ebay.com/itm/196288462626 I´d buy a new one.

-

no one knows the history of this machine maybe one of the former owners had the same idea and change the NB some time ago. Who knows?

-

Seiko STW-8B Seam length and presser foot height -

Constabulary replied to Zonker62's topic in Leather Sewing Machines

The Juki 562 / 563 manual is probably the closest for your SEIKO STW8. See attachment. Can you post pictures from the underside of your machine maybe the stitch length has been limited for what ever reason. Juki 563 562 Manual.pdf -

Hook to Needle Distance: A Compromise

Constabulary replied to friquant's topic in Leather Sewing Machines

You probably have to play with the needle bar height. Have you checked the NB height / needle - hook timing? Procedure should be mentioned in your manual. If it was me I´d probably try lo lower the NB a tiny bit so you will have a bit larger thread loop. But thats just me from a distance. Hard to tell what it going on when not in front of the machine. -

looks good, hope you have fun with this machine and it suits your needs 😃

-

Seiko STW-8B Seam length and presser foot height -

Constabulary replied to Zonker62's topic in Leather Sewing Machines

The Seiko STW-8B basically is a later / more modern clone of the Singer 111G156 with some differences but it basically is a very similar machine. How long is your maximum reverse stitch length? Usually when the reverse stitch is longer the forward is shorter (and vice versa). With other words, usually F & R are equal at approx 5mm at this type of machine (Singer 111 and later clones) so when the F is 3.5mm then usually the R is longer and I guess it is 6.5mm. -

New sewing machine! probably too much for what I need.

Constabulary replied to gordonl's topic in Leather Sewing Machines

Good Lord 😲 - needles to say yours is bigger than mine. And I say this w/o any envy... 😁 $400 for sure is a good deal - money wise. But otherwise it pretty much is an overkill for most projects, Bigger is not always better. Maybe setting it up selling it and looking for something smaller would be a good idea. But due to its size it could take some time to find a customer. There is big $ in machines of this size. -

looks good so far - how ever some fine tuning could be necessary. Little hint - the thread should run above the thread lever and not under it.

-

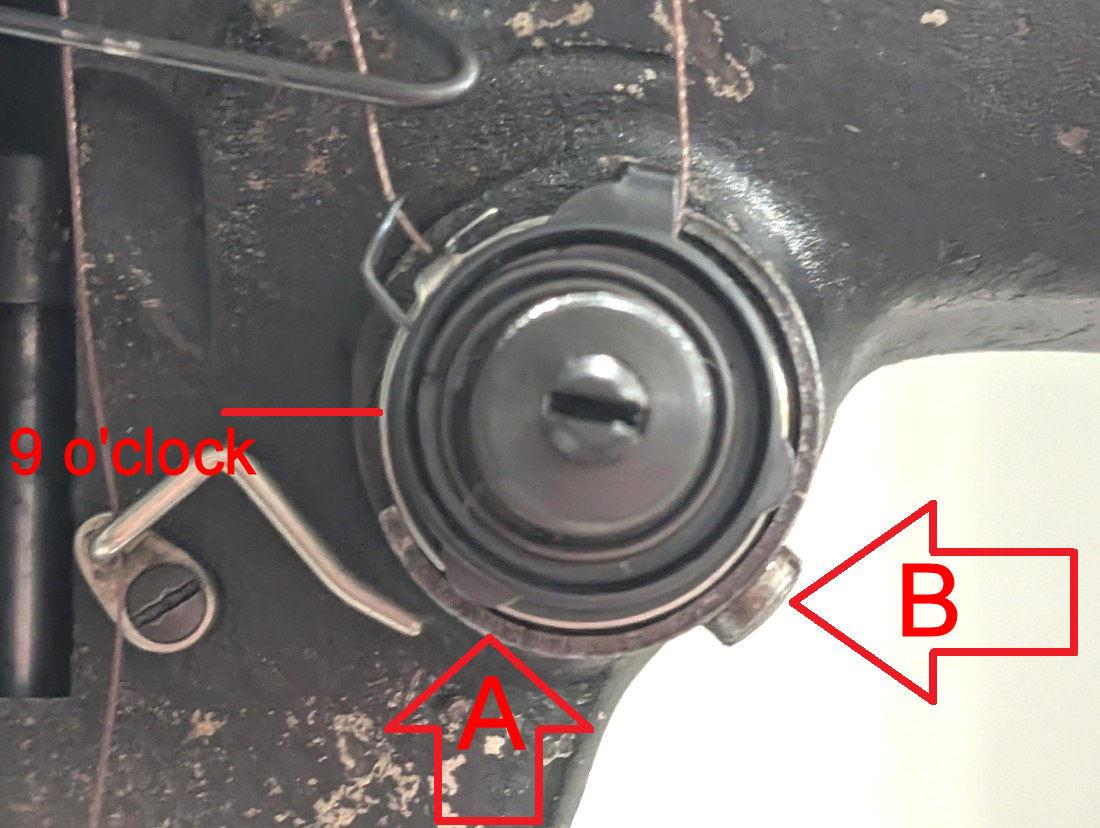

The check spring should rest in ~ the 9 o'clock position. There is a curved metal piece (A) underneath the tension unit that is secured by a screw (B). The end where the check spring rests on should be at approx 9 o'clock and the check spring needs a little pretension so when the thread lever goes down the spring goes back on the rest.

-

some Singer machines have a crazy thread path and an "odd" / unnecessary thread loop or hole - don´t know why. My 108w20 also has this path and I do not follow it and it works w/o problem. Beside that you have not instated the new tension unit correctly therefore the machine will not work properly. Not much time atm, have to run, more later....

-

But the machine has no needle positioner as it seem (see hand wheel) so in this case the white plastic nub has no purpose.