toxo

Contributing Member-

Posts

2,263 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by toxo

-

I'm liking my LS341/2750 clone more and more. I'm hating the pedal lift with a vengeance though. One of my "benches" is an old Singer table with the motor and knee lift still in situ. Yes, I determined to rob the knee lift for the new machine but when I got under it yesterday I found the rods went through the oil tray instead of individual pillow blocks. So I'll be off to the engineers very soon. I've found the pedal lift to be very hard so I'll probably install a spring somewhere to assist the knee. If anyone wants the clutch motor they can have it for free. It was a bit whiney when I got it a few years ago so I replaced the bearings so it purrs now. Make a good motor for a project.

-

I agree it's easier from a tube but for smaller jobs I'm reaching for the basting/double sided tape more and more. It's even less messy and quick. You don't have to wait for "tacky". I found a bit of Cechaflo @ 9.52 mins. Binding a floor mat - Car upholstery (youtube.com)

-

That's cheating Fred. I must say it's easy to use from a tube but I was thinking more of a pouring version. I normally buy from my leather place who pour it into jam/coffee jars and it's good stuff but I find I'm having to "liven" it up every now and then with solvent. I use one of these which makes it last longer. Plastic Leather Craft Non-Spill Glue Pot Cement Keeper Anti Evaporation 1L 1.5L | eBay I keep meaning to ask Cechaflo what he uses because it always seems so nice to use.

-

What's our favourite glue that stays fluid even after infrequent use?

-

On FB. Ideal for someone who likes making stuff shiny again. (1) Marketplace – Leather workers / saddlers / cobblers tool | Facebook

-

Bought a pair of these. They're doing the job and have enough flexibility. Thanks guys.

-

TV sports commentators, especially the BBC. Usually they're experts at their sport but no consideration is taken for the rest of us that just happen to catch something that might be interesting and don't have a scooby doo what's going on. It would be great if one of the commentators was a novice and asked basic questions of the expert so we all know what's going on. I tuned into the paralympics the other day and if you were lucky someone might say "This is the mens GK or XY category ???? No mention about what makes up that category, what these athletes are dealing with. I watched a cycle race in the velodrome where one guy with one leg was racing against a guy with two legs???

-

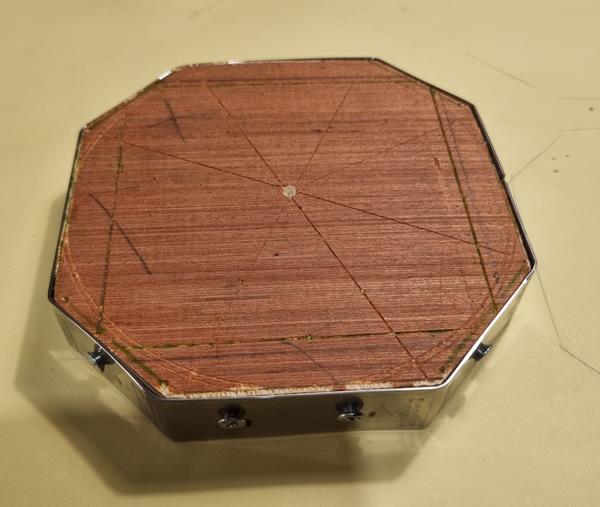

I'm halfway down a rabbit hole! Ever since I've been doing leather stuff I've been drawn to patchwork. It lends itself to many design and colour combinations, can have great impact and can use those pieces of leather that are just too small for something bigger. Trouble is I'm not a lover of those rough edge overlap seams. I like decorative seams like the French seam where a contrasting thread can really pop. A way to combine the two has escaped me until now. I decided to re visit patchwork this week and I think I've made progress. The problem has always been the bulk of four layers of leather where they cross. Being an ex engineer I don't know why the idea of a mitred joint didn't occur to me before. I cut up some old leather and had a play. Had no idea how hard it would be getting all the angles the same else they won't line up. This is the first attempt, cutting the shapes by hand. It kinda worked but I found that the stitching line is important to avoid the bunching up in the middle. If the seam allowance is too small you'll end up with a hole in the middle. I decided to make this cutting die. It was better but I couldn't get it perfect with the tools I have. This was better but still not right. Still bunching in the middle. Almost there. I shortened the seam allowance and no hole in the middle. Bear in mind those decorative stitches won't be done until after any lining is put in and those stitches will go through all. Remember, this was just to prove a theory. Any and all advice will be very welcome.

-

Fed up with the little cuts and nicks, especially if doing one that's a bit tricky. Remember I don't have one of those fancy machines that make it easy. I remember reading about a kind of chain mail glove that was an arm and a leg. If I have to bite a bullet I will (before someone tells me it's not a cheap hobby) but a quick search trawls up some cut resistant gloves. They're quite cheap and seeing I might make a die once in six months I'm wondering if they'll do. I don't need a slicing protection. It's just a handling thing. So I'm asking you guys if someone can recommend something please. I am probably gonna order something for tomorrow so I can get on but it would be good to have something that I know will work.

-

Never was a truer word said.

-

I have a few thin black skins that I think are goatskin. Even has the white line on the flesh side. It's very soft but it tears easily. Is this Nappa? If not what is Nappa? And what do I have?

-

Not to distract from your thread but here's an extension of my engine block story but it is about welding cast, aluminium this time. My "office" was a large ex blacksmith type forge. Covered in dust and cobwebs, it had a whole wall off pigeon holes that were full of stuff that hadn't been touched for years. An Aladdins cave for me because some were full of all types of arc welding rods which I could experiment with (I was quite young at this time and very much learning) including cutting rods, dissimilar metal rods, stainless, aluminium etc. One day a tanker came in and I was asked to have a go at the ladder along the top that had broken a couple of welds. I told the foreman that I'd never done it and he just said "Have a go", I found some rods that were half as long again as a normal welding rod, got up there and cleaned up the area . Then I found out why the rods were much longer than normal. (I'm sat here laughing now at the memory). As soon as I started it took about five seconds for the rod to burn down completely. With the thing being so long to say it was difficult would be an understatement. I did eventually get it done but it wasn't pretty. Just another one of life's stories.

-

People often think they've done it but they don't notice that hairline crack running alongside the weld that tells you that the crack has just moved from where it was to where it is now.

-

What is this machine for? Leather Edge Bending / Folding?

toxo replied to Constabulary's topic in Leather Machinery

Wow! All questions answered even if it does take 7 years. -

Can you use an embossing plate without a clicker?

toxo replied to DaleksInc's topic in How Do I Do That?

If nothing else, dampen the leather slightly and squeeze between couple of boards with some clamps will get you out of trouble. -

Outstanding job. As an ex fabricator/welder I know how difficult it is to weld cast anything. In the days before mig I worked in a place that repaired cracked engine blocks. They would build an oven around it with fire bricks and gas jets. Leave it burning overnight till cherry red and two old boys would sit on an upturned bucket, stripped to the waist and set to with a really long oxy torch wrapped in asbestos and wire and cast rods as thick as your thumb. They had a bucket of water to quench the torch in. Amazing.

-

I wanted a new design so I drew this which I quite liked. So I made this to make it easier. I'll let you know how it turns out.

-

Various patterns filled with sweet smellies to protect from the plague and offset the stench.

-

Thanks @SUP Took a lot of head scratching, mainly trying to work out how I was gonna be able to use a sewing machine guide at some point using very thin leather without marking it. The answer was basting tape. Glue the first strip down and then run a strip of BT along the top edge. Then use the edge of the BT to align the bottom of the next strip and then BT that strip and so on. No need to mark the leather. @Aventurine A very good question. Look at the one on the right and you'll see it stitched all the way around. Very finicky and time consuming which would drive up the price. I could glue the edge with colour which again adds to the time. I don't think this is a "premium" product which puts me in one of those quandaries that pop up whenever money is involved. I think the answer lies in a wider band which would be easier sewing around the edge. I would have to make another clicker die cos I don't have a wider one.

-

The sewing shop that hangs a few of my offerings has a good percentage of lbgtqxyz etc ? I mentioned that I might try some pride stuff and she said it might go down well especially as she is taking a stall at a big pride convention thing in August and she would take some things with her. This is my first attempt. I'm aware that we don't make much on keyrings so this is upholstery leather on some stuff I was never gonna use so ok on materials but that was eclipsed by sewing time. By the time I got to the first picture I hated my sewing machine and I absolutely knew that some bits would be unusable but hey! We have to experiment don't we! This is what was in my minds eye when I started and although it doesn't look as though there's much to it, it took a surprising amount of work. Was it worth it? I'll let you know.

-

You could try asking Oklaroots on you tube. She uses them quite a bit. Not usually for leather but that doesn't matter. Come back when you find em. I did a quick look a while back.

-

I must have a good one. I have one motor, if I'm turning corners I press lightly, it skives, if I'm on a straight bit it goes as fast as I wanna press and it skives. I should add that it doesn't get used that often.

-

Welcome from Kent, UK.

-

Fair enough. I'm just trying to be helpful here. For a normal bag I'd agree with you. But my heavy duty shopping tote is around a foot or more wide when full and my handles are useless and I'm thankful for the shoulder strap.

-

If I was gonna be picky I'd say make the handles a little bigger to go over the shoulder or add a shoulder strap cos when it's loaded it's gonna be heavy. But still a great job.

.jpg.344fcb73005c7123e62f22e8c3015451.jpg)

.jpg.f58794f9d5717f6785d822ffeb631558.jpg)