toxo

Contributing Member-

Posts

2,261 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by toxo

-

Haven't done serious photography for a very long time but here's a few ideas. A busy background like the Navajo blanket is a no no when you want the featured item to stand out. If you have no choice regarding the background choose a setting that gives very little depth of field so the item is in focus but the background isn't. You have to be pin sharp with your focus with a narrow depth of field. A light box can be as simple or as complicated as you like. Are you talking natural light, or indoor light of which there are many types. Small items could go in a large ice cream tub with light bouncing all around from within or without. If you're thinking about a bigger, permanent set up you could use a large box with maybe a couple of moveable sides to direct the light. We've all seen the photographers assistant with the hand held reflector to direct the light. The colour of the inside of the box will affect the kind of light you end up with. As well as sharpness, look at the shadows. Do you want more or less detail in the shadows? In my day we used to say practice practice and then practice some more cos film is cheap. Digital is much much cheaper. Good luck.

-

It's all been said Ryan. I wouldn't have the patience. Very very well done.

-

Speed Reducer And Servo Motor?

toxo replied to buffalobill plus Ed D's topic in Leather Sewing Machines

Nobody has mentioned installing a larger pulley to replace the hand wheel. I replaced mine with a 170mm pulley and it made a considerable difference before buying a servo motor. Speedwise, I'm now where I want to be apart from a sudden start which I think I can alleviate with the treadle position. -

Jay, there's some good advice there. I don't know if you have a budget and allergies notwithstanding I just wanted to say that it's easy to do some basic stuff with hardly any tools whilst you learn about what tools to buy and for what purpose. For example a sturdy fork can replace a stitch liner/groover/creaser. Any straight edged piece of metal will do for cutting against instead of strap cutters. Instead of stitching paraphernalia, use rivets. Don't even need a rivet setter for learning just a small hammer. There's no doubt that the right tools will help enormously once you understand when to buy basic or quality. One cheap tool which I would advocate from the get go is a decent size cutting mat. not only will it keep your blades sharp but the lines will enable you to keep everything straight and square. There are patterns to be had all over the place, some free and some you have to pay for. Take a look at this one. Not free but really easy to follow and there's a video showing how to. Good luck. I'm sure you're going to love your leatherwork as we all do. https://www.leather-patterns.com/s/search?q=Dog harness pattern

-

If you like that kind of story Shielajeanne. on BBC iplayer last week about a herd of elephant that was saved and looked after by a guy who died years later and on the day he died the herd trecked twelve miles and stood in his garden silently for two days AND they come back to the house every year on the anniversary of his death. It was episode 1 of a program called "Animals In Love"

-

Very nice and neat. Something to aspire to.

-

The strap sizes took some working out but it was ok in the end. It isn't finished and I know I should have treated/burnished etc but I just wanted to see it working. Short strap through the belt loops. Long strap. Long strap Belt loops.

-

I would have liked a smarter solution but I think the only way is a strap end snap hook on each end with a cut strap and conventional buckle so in belt mode the strap can go through the belt loops on the back of the bag and attach to each other leaving the buckle to take up the slack. Will probably mean more keepers to cater for the extra length of the strap.

-

Thought I replied on the other comp?? Mustn't have sent it. Will have a look.

-

A valiant effort Fred and I will look at it but that will still mean a hip bag where they were thinking of through the belt loops on the back of the bag to make it a waist bag. I can't get past a snap hook at each end with some sort of length adjustment.

-

I've got some of those Fred but don't see how they would work for both purposes. Unless maybe you install a buckle at each end with one end able to use the buckle at the other end? I can't believe I'm the first to have this problem.

-

Good stuff. A lot of work has gone into that. well done.

-

Just made a couple of small bags for my daughters. Can be over the shoulder (D rings) or on the belt (belt loops on the back). The question is, what do I put on the ends of the strap to make it serve both purposes without the need for a separate belt?

-

Wow! That's some sewing machine. Was that a coin it sewed through?

-

Sugar Skull Tote Bag

toxo replied to AndyL1's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Good job. Love the fastener. Did you stamp the border after painting? Belay that. Just had a closer look and I can see you didn't. Well done. -

Excellent work all round Alex. You have a good eye for detail and design. One thing that puzzles me with the roll top backpack is the length of the strap. I always thought the roll top design was for extra capacity when needed yet the strap isn't long enough for the top to be unrolled and still fastened. Ive noticed this on a few roll top designs. I think, on the original designs they had tie strings for that very purpose.

-

Personally I've never got hung up on brand names but you seem to have a burning passion going on and that's rare so go to it. I wish you all the luck in the world.

-

If you live in London the place to go first is JT Leather in Balls Pond Road. More leather in there than you can shake a stick at. All the advice you need and you can feel it before you buy it. https://www.google.com/search?q=jt+batchelor&client=firefox-b-d&sa=X&stick=H4sIAAAAAAAAAONgecSYyS3w8sc9YamESWtOXmOM4uIKzsgvd80rySypFPLhYoOyFLj4pbj10_UNyy3N0s3KszUYpHi5kAWkFJS4eCf575QTXZP6-b-WEOfVJPOVs2TKPAQN1Ey7gp4c3saziJUnq0QhKbEkOSM1J78IAF8TVYh9AAAA&tbm=isch&source=iu&ictx=1&fir=NvtTp0b1ocuDYM%3A%2CSLbLoaM0-dbY9M%2C_&vet=1&usg=K_549bei5WrNHHVGIoEYPa4bBvoY0%3D&ved=2ahUKEwjF9pq67qrlAhUkVBUIHQ03CHoQuqIBMBN6BAgKEAY&biw=1280&bih=599#imgrc=NvtTp0b1ocuDYM:&vet=1

-

Spot on Mike. And you taught me a new word. Maroquinerie. Who'da thought it.

-

Stunning work as usual.

-

I'll have to make it up as I go. Never made anything as thin as 1.5mm before. Obviously I'll have to beef up the straps and the base but I want it to squash down so I'll play it by ear as regards a lining.

-

Another thing to think about is what you want to use it for. Most of the ones I've looked at start at 2mm. I'll ask at JT tomorrow and ask them what size it starts at and if the punches are replaceable.

-

You know what they say Heather! You must have a great mind also. What colour/leather? I have one concern. The straps that take the weight are relying on the one rivet at the top of the strap I would have preferred a keeper there so the weight is held by the bottom. (Might even do that but maybe on the next one)

-

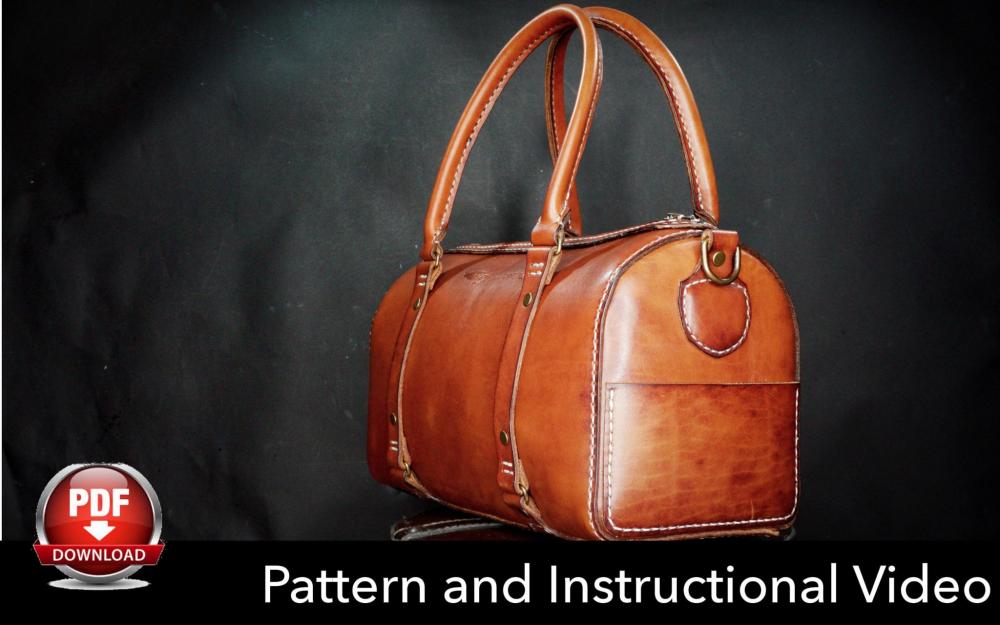

Hi guys. just started on the Weekender, the patterns come with two sizes a big one and an identical smaller one. I'll see how the first one turns out before deciding to do the two. Here's the bag. I wanted a soft version and I had to have this when I was in JTs the other day, It's ony 1.5mm so will have to reinforce where necessary. Haven't decided on thread colour yet. Wish me luck.