-

Posts

1,642 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by garypl

-

I have an old Chapman set I bought about 45 years ago as well as a newer set similar to yours and I agree that they are very high quality and, in my opinion, worth the money!

-

I believe it will be impossible to turn leather this thick inside out. It looks like veg tan and it does not lend itself to this type of construction. You need leather with a very soft temper to turn inside out after stitching.

-

I use 3M clear packing tape - sticks really well. I have also rubber cemented the piece to an old plastic place mat that you can buy from Wally World. Both work well for me.

-

Dog collars - always worked flat?

garypl replied to Klara's topic in Collars, Cuffs, Leashes and Leads

The thicker the leather the more wrinkling you will have when bending it into a circle if you glue them up on a flat surface. If the item is being made to stay in a circle, I would glue the pieces on a form or just do it by hand starting at one end and keeping the pieces curved. -

Design question. Leather LBE style suspenders

garypl replied to JeffB957's topic in Leatherwork Conversation

I say go for it - who cares what anyone else thinks as long as you like it and it fills a need for you! I’d be interested in seeing how it turns out -

Stepped WAAAAY out of my Comfort zone.. and used Paint!

garypl replied to YinTx's topic in Books, Journals and Photo Albums

Nice job Y! I have used inexpensive acrylic paint from Wally World with pretty good results. Good way to practice without spending a lot on paint. Gary -

Portfolio and Takedown Gun Case

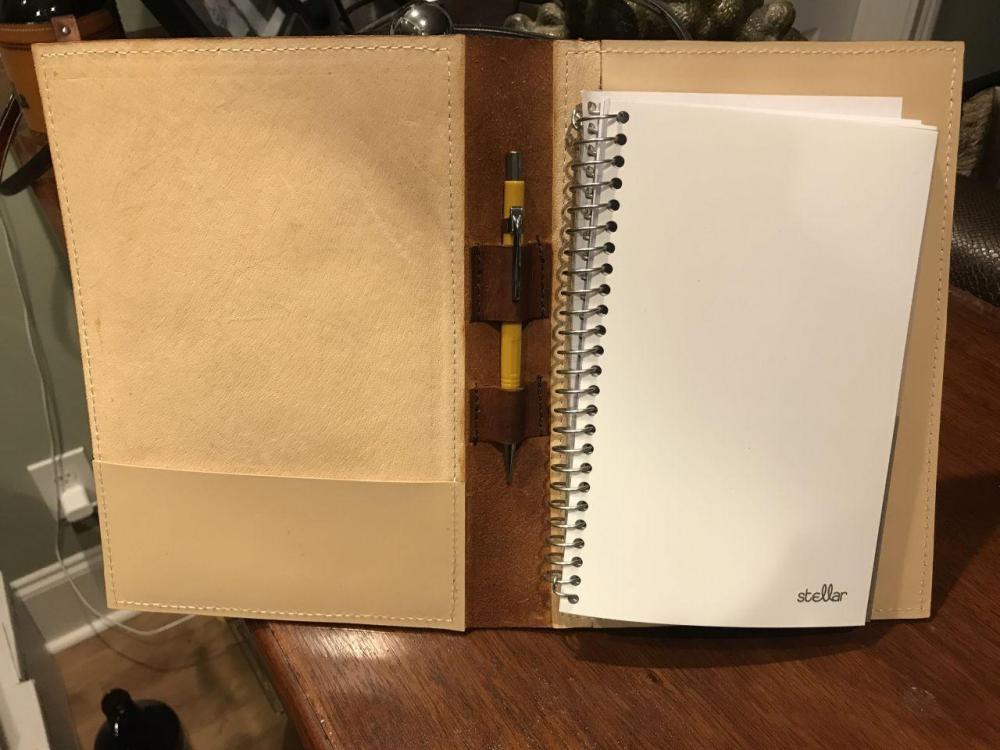

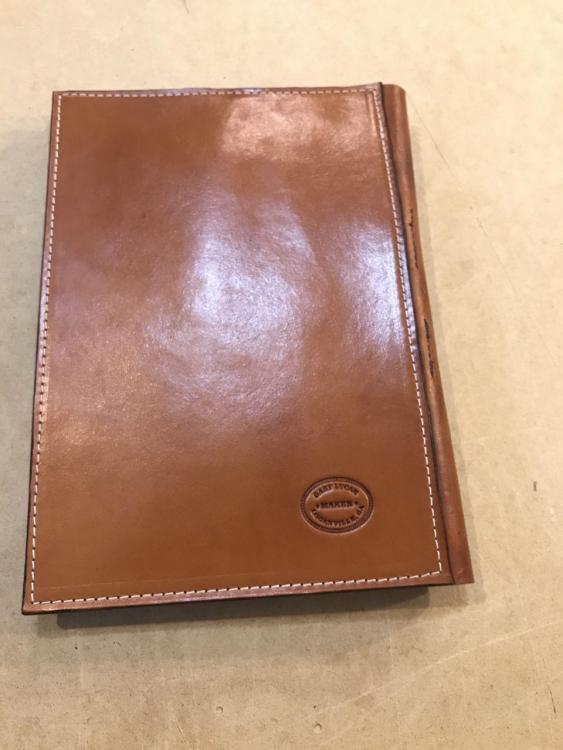

garypl replied to garypl's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks Y. I will try one of these glues. I had some concern about using the Titebond, but after testing on some scrap and sewing the scrap pieces, I didn’t see any ill effects, so I went ahead and used it. It is a pattern from Linnell. I bought a few of his videos and they were very informative - recommend them for anyone trying to improve their carving skills (I still have a long way to go!) The pen holder was a last minute add-on. If I would have thought to include this before stitching the spine I would have made the spine from 2 layers to hide the stitches between the layers - live and learn! -

Maybe the temper of the leather you used in the second sheath was softer? I once ran into a hard spot in the middle of a piece that bent the needle. In that case, I had to start over, remove the thread, and drill a small pilot hole to finish sewing. I normally check stitch appearance after the first 4-5 stitches to check they look OK. This allows me to adjust tension or stitch length before sewing the entire piece.

-

Portfolio and Takedown Gun Case

garypl replied to garypl's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Chuck - I just sized it to fit a standard 6 x 8 spiral notebook. I think the dimensions of the covers I made were 8 x 10" with a spine made of 4-5 oz. By the way, I had a heck of a time gluing the bison leather gun case before stitching it. Tried contact cement, rubber cement and double stick tape and none of them would stick due to the oily bison leather. Finally tried using Titebond wood glue and it worked great! -

Portfolio and Takedown Gun Case

garypl replied to garypl's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Jay / Chuck - thanks for your kind words. Made a few mistakes on both of these, but that's how I keep learning as I fumble along! -

Just finished a couple of first time projects. First is a portfolio I made for my friend's daughter who recently graduated from vet school and is a large animal vet. Covers made from 6-7 oz W&C and inside used calf leather. Second is a takedown gun case for a friend's Savage O/U 20 ga/22 LR shotgun/rifle made from 4-5 oz bison for case and trim. Inside is lined in waxed canvas and case is sewn with 207 thread. Has three compartments for the buttstock/barrel & fore end and an extra .410 ga tube. Made few mistakes as I learned but he was pleased with the end product, so I am happy!

-

Pulling my hair out over tension issues with Consew 206rb

garypl replied to Lokahi's topic in Leather Sewing Machines

I had a similar problem with my 206RB-4 in that I suddenly couldn't pull up the thread even with the top tension extremely tight I was using 138 thread top and bottom. It had been sewing fine and suddenly the problem started. With the bobbin case out of the machine, the bobbin thread came out easily but as soon as I inserted the case back into the machine, I could hardly pull the bobbin thread out. I tried every adjustment possible and nothing helped so I bought a new, genuine Consew bobbin case and voila, everything works again! Does your thread pull off the bobbin easily when your holding the case outside the machine? If yes, install the bobbin case and check if it still pulls out easily. If it is extremely tight you might have a defective bobbin case. My old case was not a genuine Consew case and by briefly inspecting it, I could see no visible difference between the old case and the new, Consew case. But it has worked fine since I replaced the case. Hope this help. Gary -

Josh, another beauty - very nicely finished. And I like the grips on that pistol! How long do you estimate it takes you to stamp that basket weave on the belt? I think that would take me at least two hours or more. I’ve been practicing on small pieces, but don’t feel I have the technique down good enough to ruin a belt yet! Whose basket weave stamp do you use? I am wondering if a better quality stamp is easier to use than the Tandy stamp I have? Gary

-

You got my vote! Good luck!

-

Clear 3M packing tape will keep the leather from stretching. I also sometimes just rubber cement the leather to an old plastic place mat. When you finish carving peel it off and glue residue rubs off pretty easy.

-

Very nice Cindy! That will make a nice cover for something!

-

Consew 206rb tension problems

garypl replied to LisaGingerbreadJane's topic in Leather Sewing Machines

Sounds like a similar issue although I can’t remember if I ever dropped the case. I’ll check for roundness of the case and report what I find! -

Consew 206rb tension problems

garypl replied to LisaGingerbreadJane's topic in Leather Sewing Machines

I have a 206RB that has always sewn nicely, then suddenly the tension on the bobbin thread became extremely tight. I took the bobbin case out and the thread would pull out easily, but as soon as I put it back in the machine the tension was tight. Looked for possible causes and could not find anything out of adjustment. Finally bought a new bobbin case and put it in with the same bobbin and thread and it works great again. When I have time I will compare the two bobbin cases to determine what is different between them. By the way, it is always very difficult to insert the bobbin case back into the machine. Without a bobbin loaded it slips in easily, but appears that the bobbin is hitting something when inserting the bobbin case assembly and I always have to wiggle the case and the handwheel and finally it snaps in. Is this typical for a 206RB machine? -

I would trim the pockets a bit more under the tabs - looks like it might only be @1/4" from edge of pocket to the edge of the wallet - not much room to glue the next pocket. I usually make the tabs at the top of each pocket @1/2" from the edge of the tab to the start of the pocket body - gives you plenty of gluing area for each tab. Does this make sense?

-

Round Leather Lace Making Without any Special Tool

garypl replied to nottotell's topic in How Do I Do That?

I don’t need any lace, but I’m going to make some just because it’s such a cool process!