-

Posts

1,642 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by garypl

-

Tote Bag

garypl replied to Mattsbagger's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I like that a Tiger thread - just ordered some more from Egyptian Leather - they have the best prices I have seen. -

-

Hope someone can help me identify an old Singer machine that my wife received from her aunt. The tag on the front shows AL319072. I looked on the Singer website and searched in the site with no luck. Here are some pictures - hope someone can help me ID this machine - I would like to try to sew lightweight leather with it.

-

Tote Bag

garypl replied to Mattsbagger's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Looks real nice and I like the color! What size thread did you use? I just started a tote bag today for my daughter in law. She wants to put a Mac laptop in it that measures 14x10" - I am lining the bag with pigskin, so I started with the lining, but forgot that when I sew up the bag I am losing 2" in width from both of the box ends. So now I have a pigskin liner that is too small, so looks like I will be making a smaller bag for my wife and a larger bag for daughter in law! I have to remember to measure twice before I cut the leather - luckily I had another piece of pigskin so I was able to cut out another larger liner. I have to learn to slow down... -

Let me know if you find what you need - I think I drilled a 3/8" hole in the ram and I know they have 3/8" bushings at Lowes. Good luck!

-

I bought bushings at Lowes to fit in my arbor press - they have several inner diameter sizes that should work for you and will be much less expensive than having brass bushings machined!

-

Welcome! I am in a similar position - just started playing around in the past year and trying to learn as much as possible. There are so many talented folks on this site that generously take the time to answer questions from newbies like us - I hope to improve my skills and learn so that I, in turn, can help others. Look forward to seeing progress in your projects!

-

I just received the same email, but I am wondering if Tandy is also planning to send the email concerning free Elite membership to military veterans, as was suggested in a different thread in this forum? Has anybody heard anything new about this?

-

Very interesting and informative video - wish he would have explained Latigo leather - or is this essentially the same as oil tanned?

-

Good tips Ferg - I haven't finished any large pieces - mostly small items like eyeglass cases and wallets, so has not been an issue yet. I'll take your advice when I work on a larger item!

-

I use the edge applicator that I bought from Tandy and it really works well. Just dip in the edge paint and roll along the edge for a nice even coat of paint. I have a bottle of black edge coat from Tandy that will probably dry out before I use it up! Clean up takes 15 seconds - just hold it under the faucet for a few seconds and it rinses clean.

-

I just made a wallet using sheepskin on the outside and it is very soft and pliable - this is the first time I used sheepskin and I worry that it will hold up under use - small snags seem to easily cause tears.

-

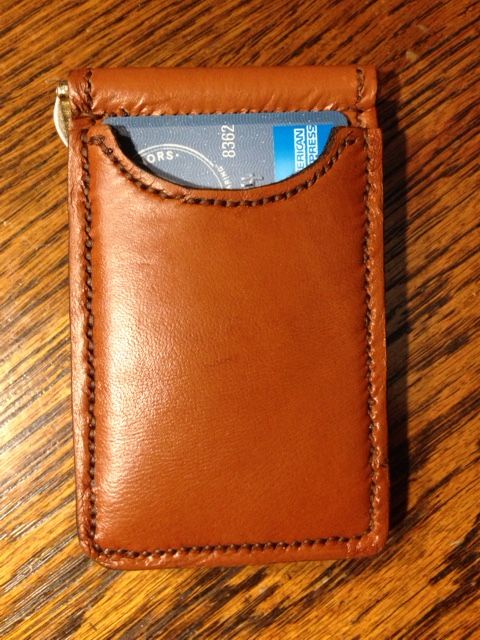

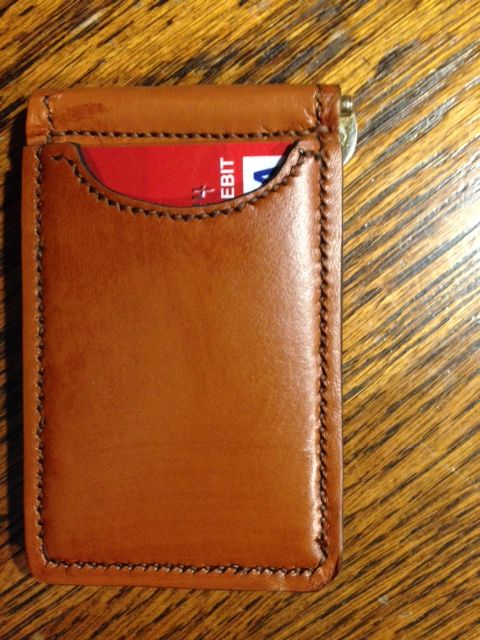

My friend had an old wallet that had fallen apart from usage/age and asked if I could make a replacement. Here is the result. Used thin veg tan inside and sheepskin on the outside. I was not happy with the results because the sheepskin seemed too soft/flimsy and puckered up in a couple of areas of the stitch line. I used 6mm Ritza thread and a 2.7mm pricking iron for the stitching - looks like it works out to @10 SPI . I figured this would be a good project to practice my stitching. Each pocket will hold two credit cards and the money clip inside was removed from his old wallet and reused. I sealed the wallet with a mixture I made that contains beeswax, lanolin, neatsfoot oil and a bit of carnuba wax. I rub the mixture in, heat it a bit to soak in the leather, then buff with a clean rag. This is my first attempt at a wallet and I look forward to making another one to learn from these mistakes. I will appreciate any critique and suggestions for my next attempt! I really enjoy reading all the great information provided by the other members of this site and I hope I can add my own tips as I improve.

-

Snaps/rivets/makers mark...press to use?

garypl replied to Double Daddy's topic in How Do I Do That?

I picked up a 1 Ton arbor press from Harbor Freight and made some of the typical modifications described in previous posts here. I also added a few changes: 1. I bought 1/4" nylon spacers from Lowes and cut them to 1/4" - put them in the arbor press housing so they rub against the side of the ram instead of the steel bolts pressing directly against the ram. 2. I drilled a 3/8" hole into the tip of the ram and made a leather punch to create stitching holes in thick leather. I drilled a small hole in the end of a piece of 3/8" iron rod to fit the shaft of a leather needle and used an 8-32 set screw to hold it in place. Also made tips to use as punches, and bought a 3/8" O.D. bushing to hold snap setter and stamping tools. The sewing needle goes right through several layers of thick leather - much easier than using my awl. 3. Removed the steel plate that presses against the front of the ram and replaced with a brass plate to reduce wear on the ram. Also replaced all of the cheap bolts with better quality steel bolts. Next step is to make a table and fence to use when stamping leather. I'll post pics when I finish.- 2 replies

-

- arbor press

- snaps

-

(and 3 more)

Tagged with:

-

There is an off-the-shelf product called Kroil that works well on frozen screws. In the US you should be able to buy from Midway USA or Brownells and probably from a well-stocked hardware store.

-

Check out Egyptian Leather on Etsy - they offer 8mm Ritza thread. They are located in Washington state.

-

Leather Stitching gloves

garypl replied to Forester's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I wear nitrile work gloves that I bought at Sam's Club - 12 for $10 - they are very form-fitting and allow me to get a good grip on needles. They are red cloth and black nitrile and last a long time. -

I've ordered Ritza thread twice from Egyptian - shipped quickly, price was $28.50 delivered for 500m roll (used my discount coupon.) The thread works great for me and I recommend giving Egyptian a shot.

-

Nice looking holster Bob! I haven't tried smoothing liner leather yet - it was a technique suggested by Josh. When I fold my Blackhawk holster, I will try Josh's technique to smooth the leather with a smooth hammer. I will post results. I always wet leather when bending it. I have made a couple of knife sheaths and shooting bags and I don't think it would be possible to bend the leather without wetting it first. Gary

-

Thanks Bob and Josh for your ideas. I already glued the liner so if it wrinkles I will try your method Josh to smooth it out. l am learning that there are typically several ways to do the same operation and I keep an open mind to trying different techniques to find what works best for me. My progress has slowed a bit lately due to workload, but I will post updates on my new Ruger Blackhawk holster, good or bad! Gary

-

Thanks for the additional tips Bob. I never tried this method, but I had the same problem trying to punch holes in thick leather without moving the glue joint - just too much stress pulling the diamond chisel out of thick leather. I would have thought that the liner would bunch up unless it was glued over its entire surface. I guess it is only held in place by the stitches around the edge? I already started a second holster and used leather that is about 1/8" thick and lined it with some very thin veg tan leather. I made and cut a pattern, then glued the liner - I already see what you mean about the wrinkles. I will post some pictures as I progress with the new holster - I am learning new techniques every day!