-

Posts

1,229 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Halitech

-

Honestly, until I replaced the rivets with either rivet and burr style rivets, stitched the snap and handle ends, or did a bleed knot on both ends, I personally wouldn't sell it. You get a 100 pound dog pulling on that with some good hard jolts, and the dog is running free. I sell 6' leads using bleed knots for 60.00

-

Shotgun Case Pattern

Halitech replied to rktaylor's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Tandy has their patterns for free. Check this one and see if it is what you want https://www.leathercraftlibrary.com/product/1220/shotgun-case-and-bird-bag-pattern-pak-2691 -

Are you using diamond point chisels or are you using small lacing chisels?

-

only 1 problem with that, unless you have 2 opposite sets of chisels that face opposite directions, the slit will be in opposite directions on each side and that will not give you the angled stitch most people are looking for.

-

Looking for Options for Thin Leather

Halitech replied to NewfoundlandLaw's topic in Leather Sewing Machines

Honestly, unless you use pigskin lining leather to completely assemble your wallet, you're going to end up thicker then 2-4oz. I make my own interiors out of roo and mission grain pigskin and by the time you add an outershell, you're around 7-8oz. Make them out of 2-3oz veg tan, and up there a bit more. I wouldn't bother with that machine myself. I have a used Adler 67 that I use to assemble my interiors and a Chinese Shoe Patcher for putting the interiors and exteriors together. -

Super/satin shene and resolene are relatively thin and I've run both through my AB fine without thinning. Resolene I do thin but I also thin it when using a sponge to apply it. It's also not a high end 0.2mm nozzle set either. Maybe with smaller nozzles they should be thinned more. Tan Kote I won't even put near my AB

-

if it's water based dye or topcoat, water is fine

-

I've been using cheap air brushes for years. If I spray 2oz of finish or dye, I spray 4-5 oz through of clean water immediately when I'm done. If yours won't spray, there is a block somewhere, or the pressure of the air compressor is too low.

-

If you buy a premade belt blank it will be cut to accommodate a 1.5" buckle by being 1/8" thinner (roughly 1 3/8") . If you buy a 1.5" strap, it will be 1.5" Some buckles will go 1.5" - 1.75", just depends on the maker.

-

1/4"?? that's 16oz leather. Saddle skirting doesn't even come that thick. Horse straps and reins aren't even that thick and you're looking at 1000+ plus for one of them. If you want something that thick, you're looking at stitching 2 pieces together. Not to mention, there is no such thing as finished on both sides but stitching them grain side to grain will give you finished on both sides.

- 5 replies

-

- leather

- dog equipment

-

(and 1 more)

Tagged with:

-

Questions about oiling leather and using a finisher

Halitech replied to Goblin210's topic in How Do I Do That?

Watch Don's videos again, it's not vegetable oil that he uses, it's Extra Virgin Olive Oil. And it looks like you dunked the leather in it. I have a small amount of oil in a small jar with a sponge brush. I lightly brush it on the back after I've tooled and dye so it doesn't affect the coloring hardly at all. I do it all the time. Easier to apply a light coat on the back and let it soak in the apply too much on the front and be screwed -

Tandy and Springfield leather both sell blanks. Usually the belt is 1/8" narrower then the buckle so unless you cut your own, you won't get 1.5 or 1.75. And if you want 1 5/8, you will really need to cut your own.

-

I have 1 and it works great for what I use it for. I can do a full 50" belt and more on a single bobbin. It is limited to 138 thread from what I was able to find out. I paired it with a techsew 550w servo motor and it runs great. I can stitch 2 layers of 10oz with no problem.

-

Press for Rivets and Snaps - So Confused!

Halitech replied to NewfoundlandLaw's topic in Leather Tools

I use a 1T arbor press from Princess Auto. I use it with my 3d stamps as well. I bought this set of dies: https://www.aliexpress.com/item/32801191336.html?spm=a2g0s.9042311.0.0.28884c4dlLS7bn and I use these snaps: https://www.aliexpress.com/item/32616479266.html?spm=a2g0s.9042311.0.0.28884c4dlLS7bn It does not fit the Tandy glove snaps even though they are same size. -

-

Don't need to know the brand, just take the blade out and measure the shaft. Unless it's proprietary, it's probably 1/4" which is standard for just about everyone

-

yeah, beyond my abilities as well. I can trouble shoot from the command prompt but actual coding, not my thing lol

-

All the male customers I've made belts for have requested 1.5". Most ladies have been 1.25" but a few have wanted 1.5"

-

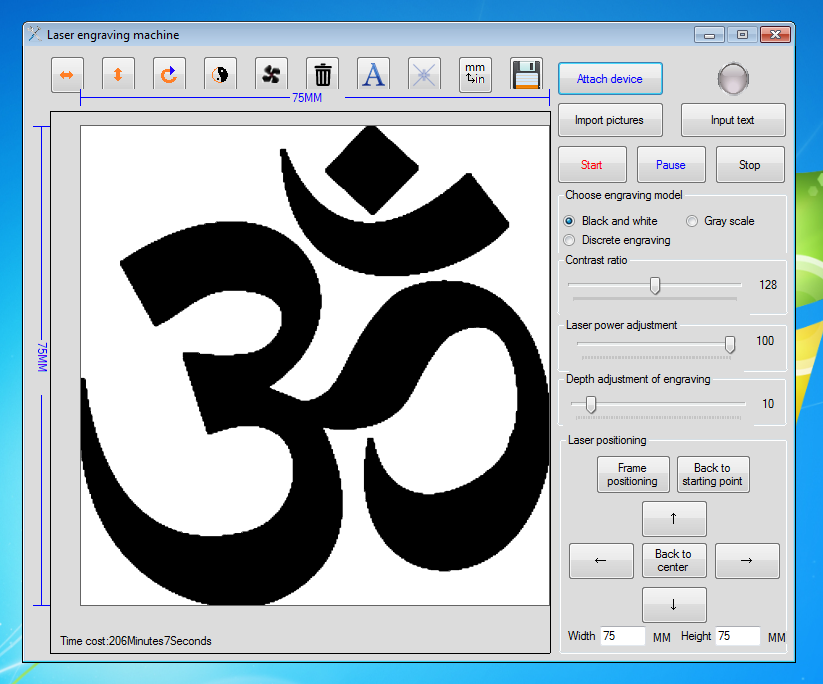

Virtual Machine. I run Debian Linux on my systems and the software runs only in Windows and Mac you would need to know the specific coding they used for commands and hacking the software wold be illegal. Although unless you spread it around, how would anyone really know?

-

For most of these smaller machines they are mostly set up for proprietary software. I wish they cold so I didn't have to use a VM to use mine

-

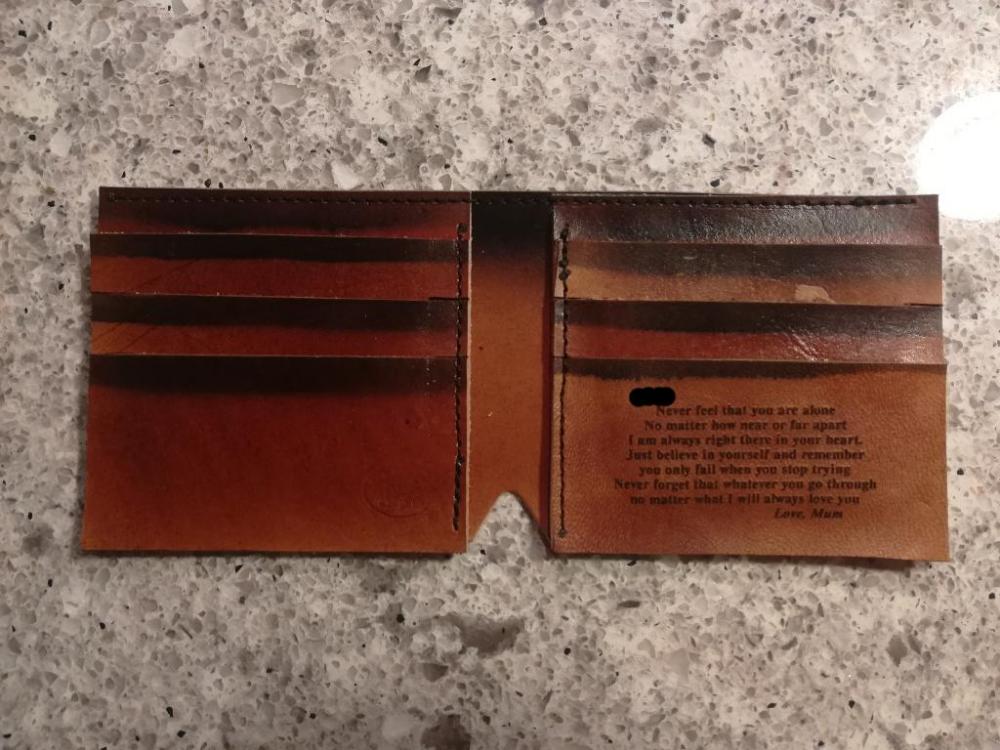

I did and the tests that I did weren't satisfactory for me until at around 80% so it's just as easy to leave at 100% and burn. Greyscale is iffy and I generally convert all my work outside of the burning program. I'm also using it in a VM because it doesn't have native linux software. Yeah, the image isn't 100% realistic, just knew it was an image the OP could try to see if it burns since I knew it did For a test, try the same settings as I used then as mike suggested, drop them down on further testing. Far as the size, adjust that down to 30mm or so just so you aren't sitting there trying it for an hour

-

The keyfob I did above used the settings in the screenshot. Default is 10 for the depth, power at 100 and it's a 1500mw laser. I only burn for 30 minutes and then stop for 30.

-

What version of the software did you use? I find that version 1.1 works the best with all the default settings. Far as images, I find line art with a .png extension work the best but try this one and see how it turns out.

-

ok, I *think* we're actually saying the same thing but you don't want to remove it all, just the antique that's on the top. If you remove it all from the cuts and tooling, you end up with nothing unless your desired effect is to waste time and money. And I don't use it to stain my leather, I use dye for that.

-

If you are using antique to highlight the tooling and cuts, if you wipe it all away, why bother putting it on in the first place? The trick is to remove enough so it doesn't flake but not too much that there's nothing left in the tooling and carving areas.