-

Posts

311 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by sheathmaker

-

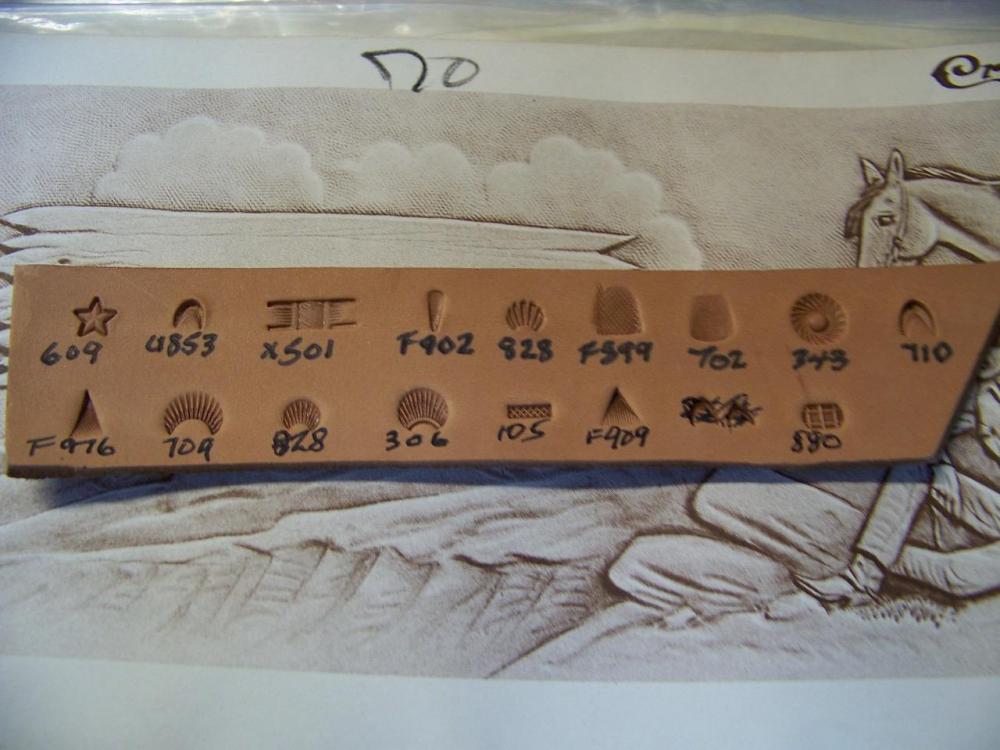

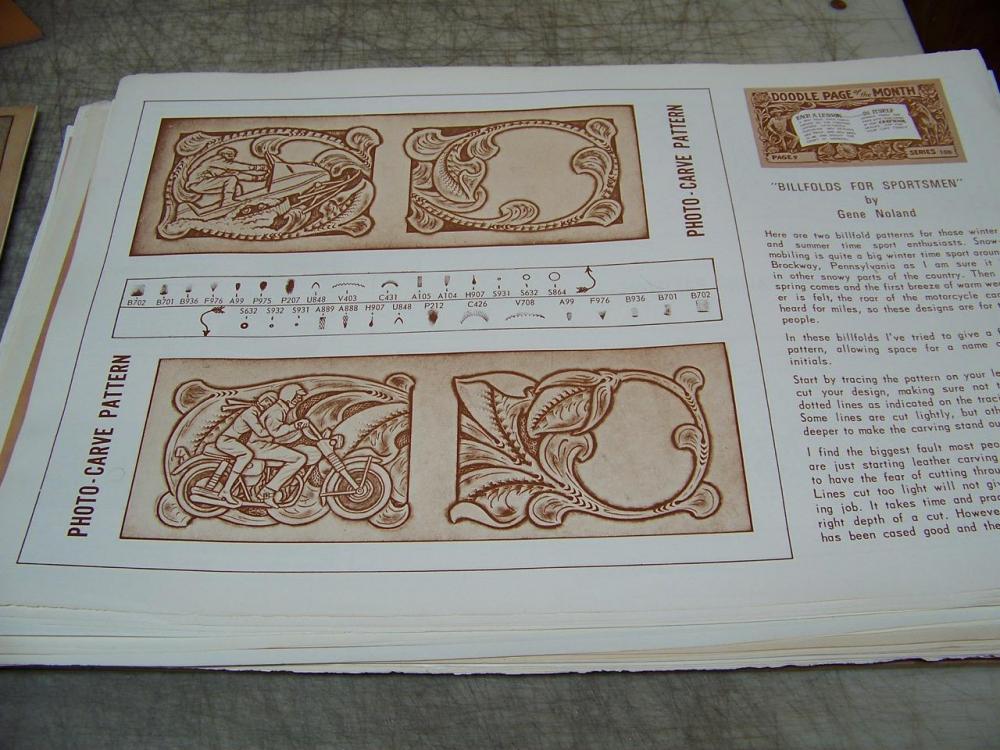

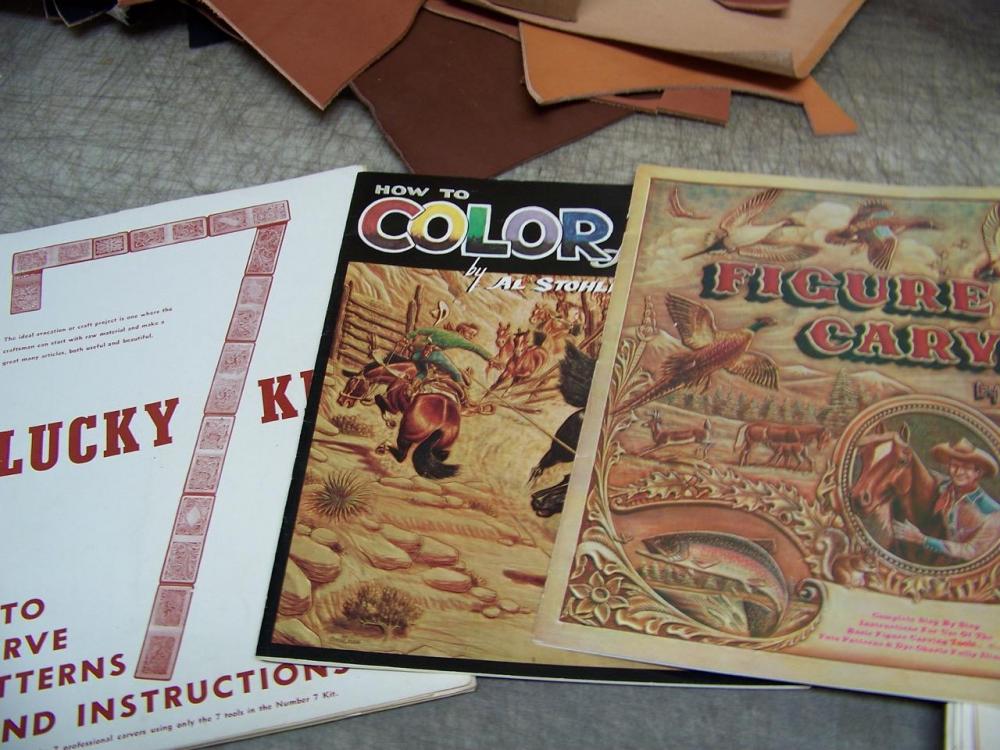

I recently purchased these from a retiring leather craftsman. If you have any interest contact me at pfl@cebridge.net or 830 367 5536 for additional information.

-

I recently purchased these from a retiring leather craftsman. If you have any interest contact me at pfl@cebridge.net or 830 367 5536

-

I have used a Cobra 18 for several (many) years. It will sew 3/8" all day everyday. My main use with it now is 69thread through and 18 needle, but I have sewed many miles using 138 when making chaps and chinks. It is a great machine I endorse it completely.

-

I think what you want done would be better accomplished with a Lap skiver. They look for all intents and purposes like an ordinary "pull through splitter". They start out at the original thickness and then progressively dig deeper until you stop and you get even skive from side to side.

-

Speed control by pedal force or movement?

sheathmaker replied to Gymnast's topic in Leather Sewing Machines

Boy, if I have ever seen a solution looking for a problem, this is a classic example. Force, movement,....who cares? I just want my machine to sew correctly when I turn it on and to start and stop when I say Go and Whoa. Now before anyone gets their feelings hurt, the foregoing is just my personal opinion and is not intended to sway anyone one way or the other, or criticize others for their opinions. I'm a believer in the old "If it ani't broke, don't try to fix it" camp and my Cobra machines have been (with servo motors) sewing just dandy since I brought them into the shop. Good luck! Paul -

It is most likely the Rose Parade in conjunction with the New Year's Day Rose Bowl.(Amercian football) The parade usually had many fancy equestrian riders almost all of which sported Bohlin or Bohlin type parade saddles and tack. It is a long standing annual event.

-

You can trust Pepin. He is a man of his word and a man of honor. Paul

- 15 replies

-

- henley swivel knives

- jeremiah watt

- (and 10 more)

-

Pepin, my friend, I am sorry to hear of this, particularly at your young age>. (I am 85, very soon to be 86). I have admired your work for many years and I still have those two marvelous scribes you sent me as a gift. I wish you well! I look forward to your eBay link . Paul

- 15 replies

-

- henley swivel knives

- jeremiah watt

- (and 10 more)

-

Skinning Knife Sheath

sheathmaker replied to CelticPrint's topic in Gun Holsters, Rifle Slings and Knife Sheathes

@TargetRockLeatherThe design allows you to follow the blade shape of the knife much more closely. The straighter the spine of the blade the less the split becomes effective, however even with a slight angle the friction retention of the knife is enhanced with the tighter split toe design, as was the case in the photo I presented above. Paul -

Skinning Knife Sheath

sheathmaker replied to CelticPrint's topic in Gun Holsters, Rifle Slings and Knife Sheathes

The deep seat of the knife, plus the friction fit generally provides more than enough retention. This assumes the sheath has been designed specifically for the knife it carries. I always start out with a paper pattern in the design process. This can and does spot problems before they even get a chance to occur. Since everything I make is fully leather lined, the wet forming is generally not possible is the usual sense, but I do "soft form" in the later stages of construction which does enhance retention. I have more then 9000 sheaths out there in the world and this style sheath is well represented among them, and so far in over 20 years of sheath building no complaints. Give it a try, I think you'll like it. Paul -

Skinning Knife Sheath

sheathmaker replied to CelticPrint's topic in Gun Holsters, Rifle Slings and Knife Sheathes

While you are prototyping, why not try a spilt toe pouch style tailored for a deep seat? Eliminate the need for a retention strap and make the handle to blade ratio not even a consideration, let alone a design problem. Paul -

I'll be there Friday and Saturday. I went to my first round Up in Burnet, Tx held out at the Airport there and then on to Brownwood, Tx, and for the last few years Wichita Falls Tx. I think my attendance has been 100% for the history of the event. Paul

-

Well, if you do run out you can get WyoSheen from Sheridan leathers. It's exactly the same as the old NeatLac. Paul

-

Right or wrong, your boss probably thinks that your apprenticeship and the knowledge you have gained and will continue to gain has a monetary value, hence the minimum wage all this time. If you have progressed to the point that he would not hesitate to put his name or mark on your work, then you probably have progressed well and maybe, just maybe the value of your apprenticeship (to you) is starting to diminish. If that is a fact it may be time to strike out on your own. Regarding making the sample shoes at your expense, that would indicate that perhaps he's not 100% on board with the ultimate value of the project, and at least to him is questionable, and he may have agreed reluctantly. I believe, if you can gracefully back out or just let it die, that might be the best. On the other hand, if he is really honestly interested, then I think the sample pair, even at your expense, might be a good idea. Keep in mind, it is not unusual for a company or business to claim any patterns etc. developed at the company on company time are indeed the property of the company. Unless you are willing tom accept this set of circumstances, I think you'd do well to just not pursue it. Paul

-

Westren Diamondback rattlesnake skin for inlays

sheathmaker replied to Garathan's topic in Suppliers

I am in Texas. Where are you located in Texas? My main use for Diamond Back is for inlays for knife sheaths and I find the smaller skins best because all or most of the diamonds will show in the inlay window. Do you have skins under the 39" you mentioned. I'd even be interested in "baby" skins say 20" to 24". I have not had good luck with Glycerin tanned skins. The very few I've tried to work with were damp feeling even though they were dry and "rubbery" and fragile, would tear or disintegrate easily. I would be interested in a sample to check the tanning results and I am happy to pay for it. My contact and address is below. -

You are absolutely right. I was remiss for not adding Paul to my list of great makers in my previous post. He certainly is deserving of a spot in the top tier.! Paul

-

Who still supplies speedy beveler for swivel knife?

sheathmaker replied to Coraxxx's topic in Leather Tools

@Coraxx, Sorry, please accept my apology. I certainly did miss that part of your post. A while back they decided not to stock it anymore so I ordered 50 of them ( they decided to restock shortly after I talked with them and placed my order) so I could have them in case any of the owners of my instructional DVDs wanted therm as they were demonstrated on the DVD. I still have 8 of them if anyone wants one I will share what I have left.. Paul -

Terry Knipschield, Danny Marlin Joshua Fields, all excellent maker. google Knip knives, Danny Marlin knives, or Fields Made Knives. You can't go wrong with any of these guys. Paul

-

Who still supplies speedy beveler for swivel knife?

sheathmaker replied to Coraxxx's topic in Leather Tools

Springfield Leather has them. They are also an advertising sponsor of this site. http://springfieldleather.com/Blade-Plastic-Beveler -

You might Google Joufuu Leather. He is in Atlanta and may be able to assist you.

-

Operating height for cylinder bed machines

sheathmaker replied to plinkercases's topic in Leather Sewing Machines

I use a bar stool in front of my cobra 4. That gives me the benefit (however slight) of both standing and sitting. I've done it that way through two machines, both 441 clones≥ Paul -

I've been using round knives (or head knives) for so long that I rarely even pick up another knife except for edge skiving or window cut out for inlays on very light weight leather. Over the years I have accumulated 11 various round knives and only one of them is not a custom made knife. It is an old Osborne that I had Danny Marlin reprofile for me and, of course, it's a terrific old knife. Danny Marlin is a really good maker and he uses a lot of L6 steel (repurposed circle saw blades). Terry Knipscheild (Knip Knives) is another very excellent maker as is Joshua Fields (Fields Made Knives). I recently got another gifted to me by T K Steingess which is only .039 thousandths thick made of AEB-L steel and it cuts like a laser. Thinner (to a point) is better, but that .039 is about the thin limit. My favorite thickness is .040 to.045 Any way the steel and the heat treat is the secret to great sharpness and long edge holding life, and unfortunately those steels cost a bit more, but considering the knife will literally last a lifetime or more the $200 to $250 you pay for a real quality custom isn't too bad in the long run. If you're like me, once you get used to the round knife, you'll never go back to the pull cut utility knives.

-

What kind of leather should I use for tack making?

sheathmaker replied to WildHorseAmber's topic in How Do I Do That?

Back when I was making tack and particularly headstalls I used Wicket and Craig Utility skirting split to 7/8. Using Barge cement and stitching I bond two layers flesh to flesh yielding a 16Oz. product. Carved, tooled, plain, fancy anything you want and because of the 16Oz weight it is/was durable and bullet proof. I guess I've made something over 400 headstalls, and breast collars, saddle bags, 100s of spur leathers. On the lighter weight items I used the same leather spilt 2/3 for the lining. The customers really appreciated the "fully leather lined" products. Also used it for the yokes and trim on chaps and chinks Paul -

Need ideas for deer hide sheath

sheathmaker replied to archeryrob's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Check out Levi Graham Knives for some ideas. http://www.levigrahamknives.com/ Paul