-

Posts

2,221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Uwe

-

Yes, it's much easier to find information about machines that actually exist. An admin like @Northmount or @Wizcrafts might be able to edit the topic title, so we don't propagate a typo for all eternity on the internet. Edit: Title fixed

-

As you already know, there isn't much available online for the Durkopp 235. You might as well be the one who starts making stuff available. Can you please get the ball rolling by sharing what you already have for the Durkopp 235? Please post detailed pictures of your Durkopp 235 and also upload a PDF file of the Durkopp 235 manual you already have. Without seeing the machine it's hard to guess if a closely related model may provide a useful starting point for adjustments.

-

If the race is missing the shuttle hook and bobbin are probably missing, too. Parts might be available, I may even have some in my stash, but you really need to find part numbers to get the right bits and pieces. Kinda sounds like a parts machine, or one that has donated some parts, willingly or not. Make sure you have time and money to invest after you buy a machine like that. This thread contains manuals and other useful info regarding the Singer 45K53:

-

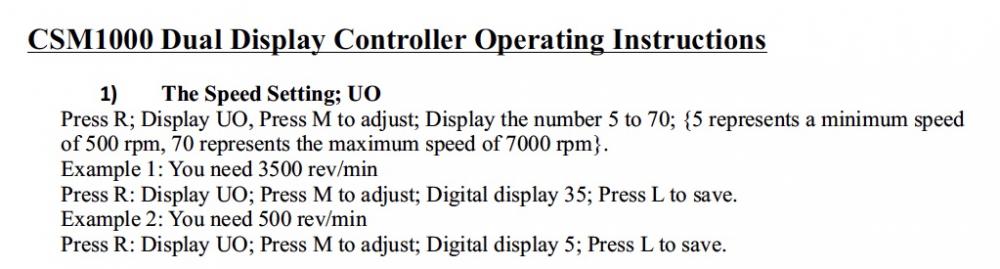

You'll have to press a few buttons to select a top speed the motor is allowed to spin at. The Consew CMS1000 manual will tell you the details. "Read manuals" sounds like a great new year's resolution.

-

This same question came up a year and a half ago. Summary: your machine is about two decades old, give or take a decade.

-

The Pfaff 1295 referenced earlier sold shortly after that video was posted. In my experience, used walking foot post bed machines in good condition are rare and not cheap. New walking foot post bed clones like the Techsew 860 run close to $3K new. New OEM machines from brands like Juki, Durkopp Adler, or Pfaff are easily twice that. You'd only need one hand to count the walking foot post bed machines that have popped up on CL in the Detroit area over the past few years. The last one I remember was a Pfaff 1296 for over $4K. Without knowing where @BrownChicken is located, it's hard to make meaningful recommendations for used machinery. I do have several post bed machines, but not all of them are walking foot designs. The only walking foot post bed I'd consider letting go for $1,300 is a Durkopp Adler 168 (once I put it back together.) My two Durkopp Adler 268's (one single, one double needle) are nearly pristine and worth considerably more. Many folks making bags manage fine using a suitable walking foot cylinder arm machine, which are generally more plentiful in supply and cheaper than the post bed versions. The cost difference is partially due to manufacturing complexity and production volumes.

-

It would be useful to know which presser feet @spurdude101 is actually using. Some combinations are just doomed. Sewing wet veg tan leather with harness feet on a 441 class machine is like olympic weightlifting in stilettos on a waterbed - interesting but not quite what you hoped for.

-

The two feet are connected via linkages and work off the same pressure spring. Any adjustment to the presser foot spring will affect both feet.

-

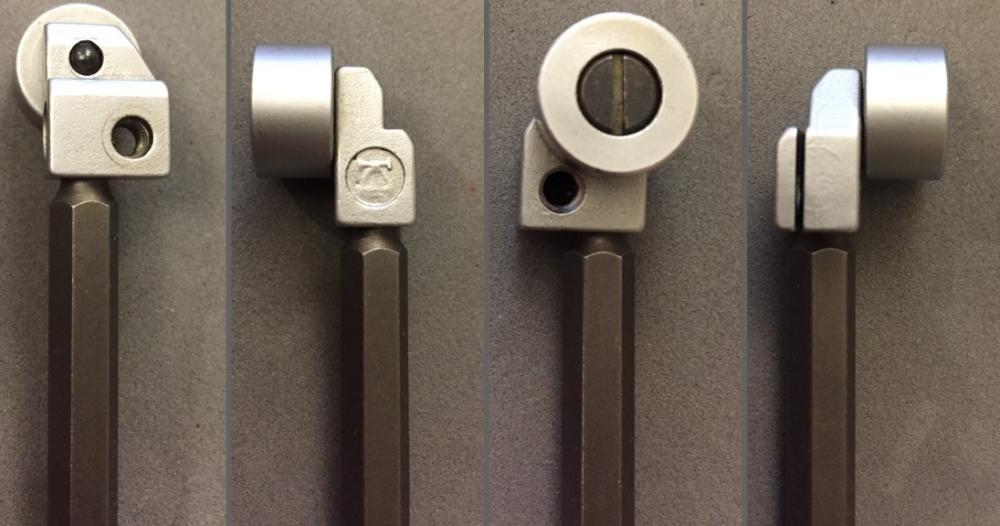

For noncritical out-of-production parts like your Pfaff foot lift roller, I'd recommend make your own, or find/make something functionally equivalent. It's not a high precision or critical part and you're free to make stuff up. You're not running a Pfaff museum, after all. For example, this roller tip from an edge guide on top of a suitable bolt/shaft/rod is functionally equivalent to your missing part. Of course your parts drawer may look different than mine.

-

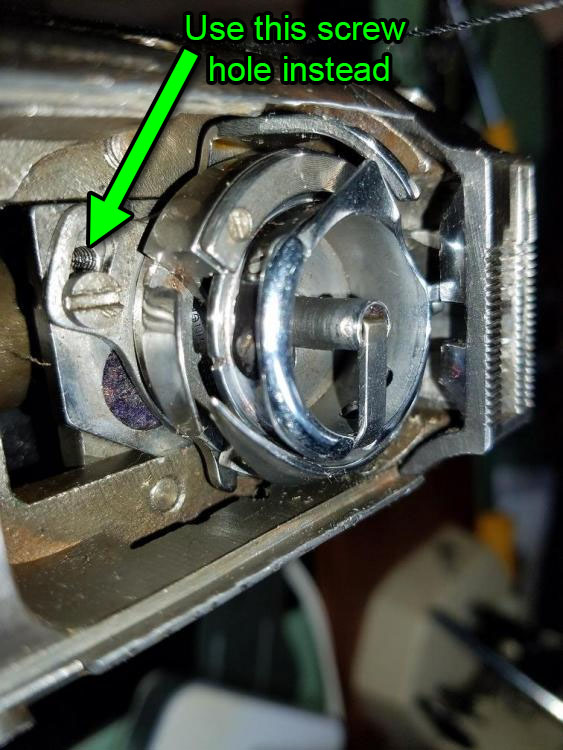

I'd try using the other screw hole first. Perhaps that is actually the original one. The screw hole you are using now may have been added to make the old combination work. Don't assume that the two holes have the same thread and pitch - you may need a different screw for the other hole. The tab on your bobbin case also looks like it's been filed down already. On my Singer 153W102 the hook saddle and the bobbin case opener finger look quite a bit different than yours, and my machine the opener is adjusted to the opposite end of the adjustment slot to make it work.

-

Consew 206RB balance and tension in reverse issue

Uwe replied to MAlan's topic in Leather Sewing Machines

Your needle size seems much too small for size 138 thread. This may cause problems because the hole the needle creates is simply too small to consistently pull the knot tight in the center of the material, especially in hard leather. To make room for a lock stitch knot, the hole theoretically needs to be about three times the diameter of the thread. Soft vinyl is much more forgiving. Needle to thread size combinations depend on various factors, but your needle is much too small according to the chart below. Stepping up the needle size may alleviate some of your apparent irregular tension problems. A whole bunch of things have to come together just so to make forward and reverse stitches line up perfectly and knots pulled tight evenly. Change one thing and all bets are off. -

Singer 153W 100 Presser Foot Position change

Uwe replied to JeffHami's topic in Leather Sewing Machines

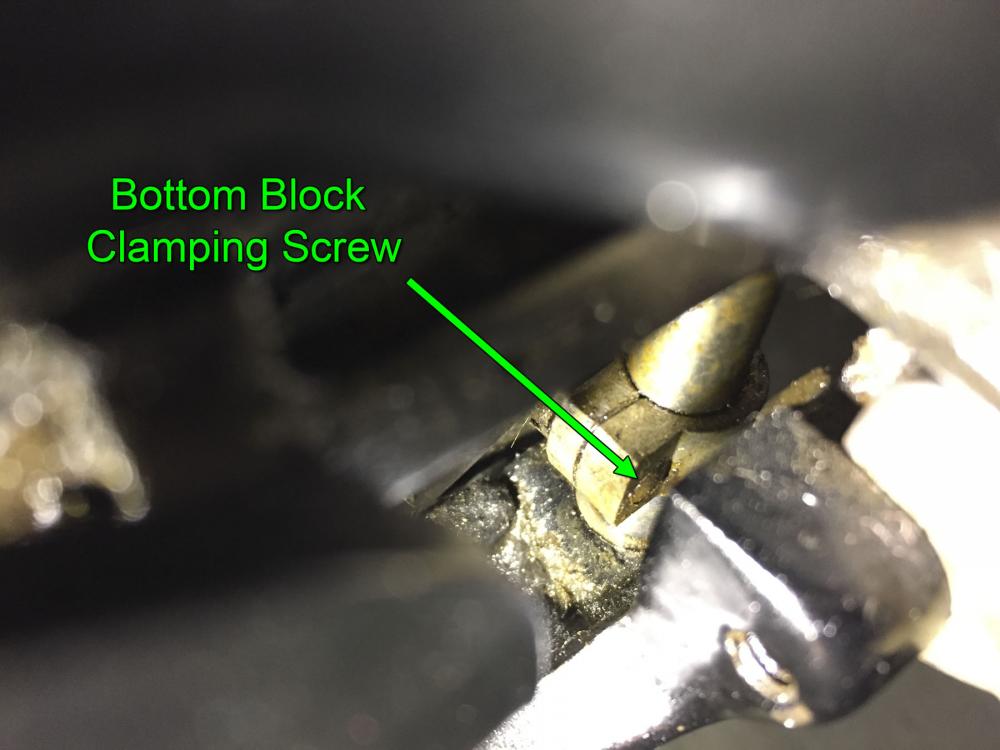

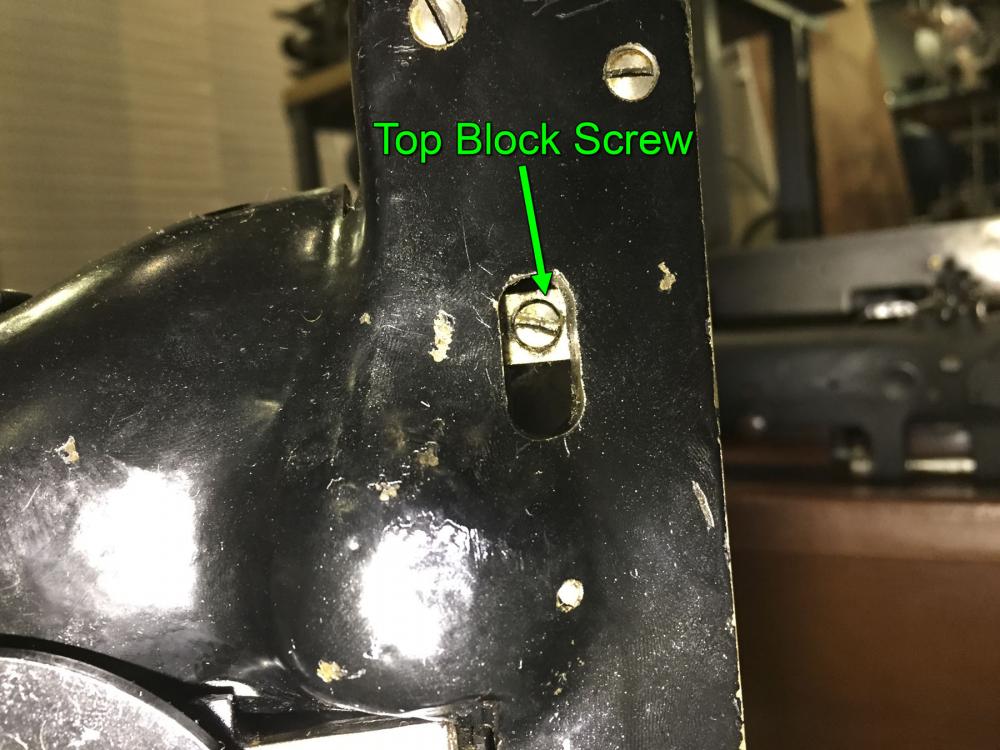

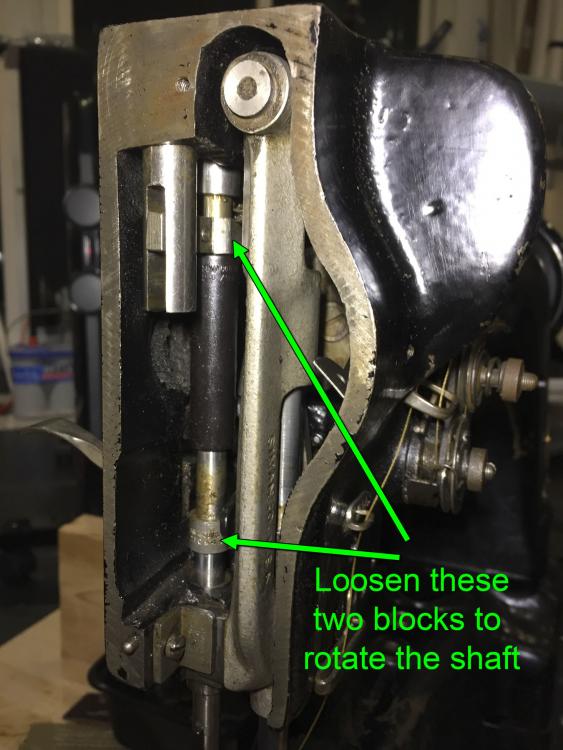

There are two clamping blocks on the presser foot bar. The top one makes sure the shaft does not rotate. The bottom one just provides a ledge for the presser foot spring to press down on. The top block has the clamping screw in an obvious, acessibe spot: The bottom block does have a clamping screw, but it's not readily accessible. My guess is that you have to first remove the presser spring, then loosen the top clamping screw, then rotate the presser bar so that you can access the bottom clamping screw from the open end of the head. Whether or not the front-to-back blade mount feet you find will work is not entirely clear. I do have various vintage Singer feet that fit the cross blade mount on Singer 153W100 and similar needle feed models, just in case you see something that will work for you. They're $10 each. -

My Pfaff 145/545 PDF manual (Pfaff 145 545 User Manual.pdf) has some service training info appended at the end. It's not quite a full service manual, more like a handout for an instructor led training class, but it's better than nothing.

-

Sunstar km-380 cylinder arm machine

Uwe replied to davehorseblanket's topic in Leather Sewing Machines

The Sunstar KM-380 uses "normal" bobbins, similar in size to Pfaff 335. On the plus side, the Sunstar KM-380 does have a full motion feed dog, which is somewhat rare among small diameter cylinder arm machines . On most Pfaff 335 and Adler 69 class machines the feed dog only moves back and forth, but not up and down. -

What type of edge guide for applique/edgestitching?

Uwe replied to SheltathaLore's topic in Leather Sewing Machines

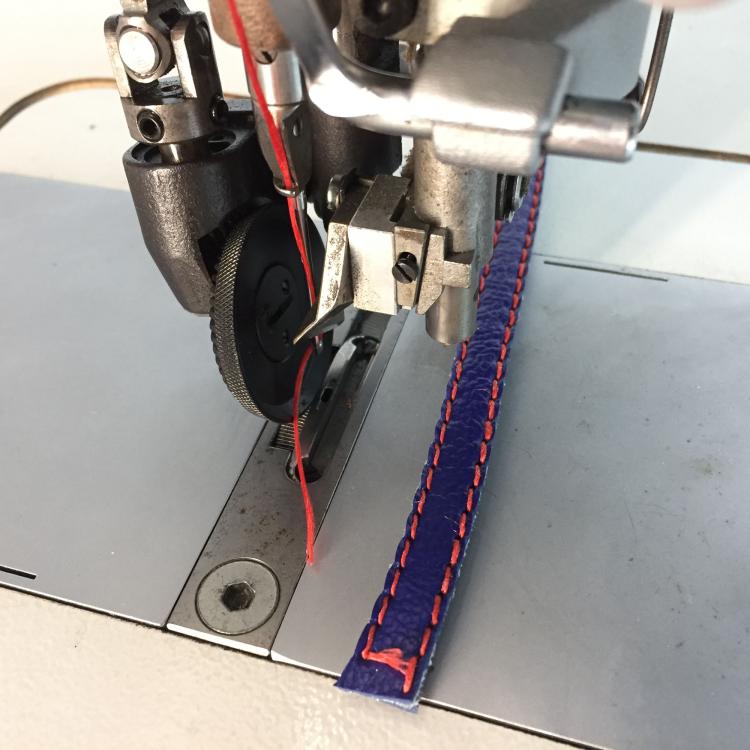

Perhaps I should have said "Sewing 1/16" from the edge along applique curves is actually a very hard thing to do well, no matter what machine you use." Vintage and modern walking foot machines generally share the same inherent advantages and limitations of that design. Modern machines are just more likely to have convenient mounting holes for swing down edge guides, and easy momentary stitch length adjustment for placing stitches in precise locations for corners and peaks, and motor controls that allow precise needle movement. Many machines that are specifically designed to produce a seam 1/16" from the edge employ and edge cutter that cuts off the material 1/16" from the seam as it sews the seam. Below is a photo of a sample I sewed on a Durkopp Adler 1183i with an edge cutter. It may look simple enough at first glance, but I would wager that this is nearly impossible to do on any walking foot machine without an edge cutter. Following curves and peaks that closely is not an easy task even on modern machines that are specifically designed for sewing extremely close to an edge, allow easy on-the-spot-turns, and where nothing obscures needle visibility. The YouTube video where the skilled seamstress/seamster follows an edge of a leaf design looks deceptively easy. I tried something far simpler on the DA 1183i and I failed rather miserably. At some point the operator is the limiting factor, not the tool. I don't really see how an edge guide could be employed to make sewing that leaf easier. -

What type of edge guide for applique/edgestitching?

Uwe replied to SheltathaLore's topic in Leather Sewing Machines

A suspended roller guide with a small roller combined with a left-toed foot would indeed be your best option, but I doubt your machine (Consew 227, right?) has mounting holes to install a suspended guide. Sewing 1/16" from the edge along applique curves on a vintage machine is actually a very hard thing to do well. -

Sunstar km-380 cylinder arm machine

Uwe replied to davehorseblanket's topic in Leather Sewing Machines

My googling brings up good info like manuals with specs: http://lmgtfy.com/?q=sunstar+KM-380 Sunstar is made in Korea. It's actually a good brand based on what I've seen. I have a Sunstar KM-380 but haven't sewn with it yet. It's not a direct copy of any OEM machine I know of, but rather a Sunstar design based on various other machines. Arm, feed dog, and throat plates are compatible with Durkopp Adler 69 class. The feet are very common and cheap Singer 111W style. I've never sewn or repaired a horse blanket, so I can't say if the Sunstar KM-380 any good for that application. Realistically, you'll probably need a Juki TSC-441 class sewing machine (for example: Cowboy 4500, Cobra Class 4, Techsew 5100, etc.) for sewing horse related items. If you're not good with a computer or figuring things out yourself, you may be better off with a sewing machine from a dealer you call for questions (check the banner ads.) Also, don't be afraid of proper punctuation. It's your friend and lets people understand what you're asking or trying to say. -

PFAFF 545 OR 1295 experience? opinions?

Uwe replied to plinkercases's topic in Leather Sewing Machines

For every Pfaff 1295 out there I imagine at least a dozen Pfaff 145/545 floating about. That means Pfaff 1295 are very hard to find and if you need one and have an opportunity to get one, get it. Most of what I know about operating the Pfaff 1295 machine was in that Pfaff 1295 demo video you mentioned. Thread capability between Pfaff 545 and Pfaff 1295 should really be very close (happily sews size 138 all day) , they may even use the same hook - check the parts lists to be sure. Both the Pfaff 545 and Pfaff 1295 I had/have are exercises in buttery smoothness once adjusted well, just a joy to use. Which one of them suits your needs better depends, well, on your needs. If in doubt, get both. Lots of interchangeable parts between them. Make sure the Pfaff 1295 has the throat plate and feed dog you need/want - those are even harder to find than the machine itself and priced accordingly. Also make sure the tension release mechanism on the back of the Pfaff 1295 is complete - it's a chinese puzzle. -

The stitch line looks good to me, actually. The seam appearance on the backside looks different than the front side, but that's mainly due to the way the needle penetrates the material on top and pushes it out on the backside as the needle exits. Fabric is a different story because the fabric's threads just get pushed aside by the rounded needle point and seam appearance is more similar front to back. Leather needles cut the material and leave a different seam appearance front and back. You can experiment with variations on the leather needle tip to alter the seam appearance in subtle ways, but you will probably be disappointed if you expect the seam to look identical front and back on leather with that machine. Of course the leather itself (type, thickness, tanning method, surface treatments, etc.) also plays a role. There are a few (monstrous and expensive) machines like needle & awl machines that come closer to a perfectly symmetric saddle stitch look on leather because the material gets penetrated from both sides, first with the awl from one side, then with the needle from the other. This double entry makes the seam appearance more uniform front to back.

-

Thank you @mashoolle for sharing your solution to this problem and documenting it so well! Nice work on that custom part, it looks very professional. I did some prototype milling with Delrin plastic and it's a great material. It's been a while since I started this topic and I now realize that I neglected to follow up with the fix I eventually came up with back then. The original little tab I had initially used was not satisfactory. After some more tinkering and online research I found arbor shims at a tool supply company (Production Tool Supply) that were just the right size and thickness. With two drops of super glue the arbor shim also worked quite nicely for keeping the thread from getting caught under the hook. Here are a few pictures of my arbor shim fix/hack:

-

That reminds me of a Singer 153W timing belt saga some time ago, where it also turned out that the belt got destroyed by fire. We never did find out if that machine was salvaged in the end. Keep us posted with your Phoenix from the ashes story!

-

Consew 227R, Adjusting Hook Assembly Height? Photos

Uwe replied to LunarConcepts's topic in Leather Sewing Machines

I have a feeling none of your throat plates were designed for the Consew 227R. If you add enough iterations of somebody making third generation copies of a part that was made for a copy of a machine, then you'll end up with parts that don't really fit anymore. Personally I wouldn't attempt modify a $800 machine head to accommodate a $20 throat plate that doesn't fit right. Try to find throat plates that fit well. That Consew 227R is very likely "just" a rebadged Seiko CW-8B, which in turn is likely based on the Singer, but not a clone in the strict sense. Look in the Seiko CW-8B parts list for part numbers and then search for that exact part number. Or look for parts that say they fit the Seiko CW-8B. Then, if they don't fit, return them. Some of our resident vendors may also be able to hook you up with throat plates that actually fit your machine. They may cost a few bucks more, but you'll be happier in the long run. Of course there's also a small chance that your hook assembly itself isn't quite the right one for the machine. -

Unsticking stitch length regulator on Consew 227 (not R)

Uwe replied to SheltathaLore's topic in Leather Sewing Machines

You are right to expect that knob to turn as it should. For some reason it doesn't. The problem is compounded by the fact that the threads on the shaft that the knob screws onto are brittle and break easily. On my machine a large portions of the thread on the end of the shaft had already broken off, leaving jagged edges and gritty bits behind. I spent the better part of an hour Dremel grinding the jagged threads smooth until the knob would thread in and out smoothly. Hypothetically, if it were my machine and I'd have not much to loose, I'd be tempted to grab some channel lock pliers, wrap a piece of leather around the knob and as gently as possible apply some twisting force on the knob in the correct direction in hopes of getting the knob to turn. I'd also spray some WD-40 or similar in the (tight) gaps by the knob beforehand in the hopes of providing some lubrication on the threads. But it's your machine and I'm certainly not telling you to do that. And you really should check in with Gregg before you do anything drastic. -

Unsticking stitch length regulator on Consew 227 (not R)

Uwe replied to SheltathaLore's topic in Leather Sewing Machines

Ah, well, that's a problem then. Has it ever worked since you got it? Either way, Gregg's your man.