-

Posts

1,352 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by particle

-

I posted a while back that I had two of his burnishers. I got the website confused with someone else's site. My burnishers are actually from Pro Edge Burnishers. If anyone needs another source for leather burnishers, check him out. I'm very happy with mine. http://proedgeburnishers.com/index.html

-

I prefer to stop my liner layer (two layers of 7-8oz) just shy of the tongue slot, usually leaving about 1/8" space from the end of the liner to the slot. This gives a little breathing room for the tongue to move without being obstructed by the lining layer. Folding over two layers of glued & sewn 7-8oz isn't really possible, so it has to be skived on the ends, and I never had good luck skiving the leather thinner at the fold so this is the method I use.

-

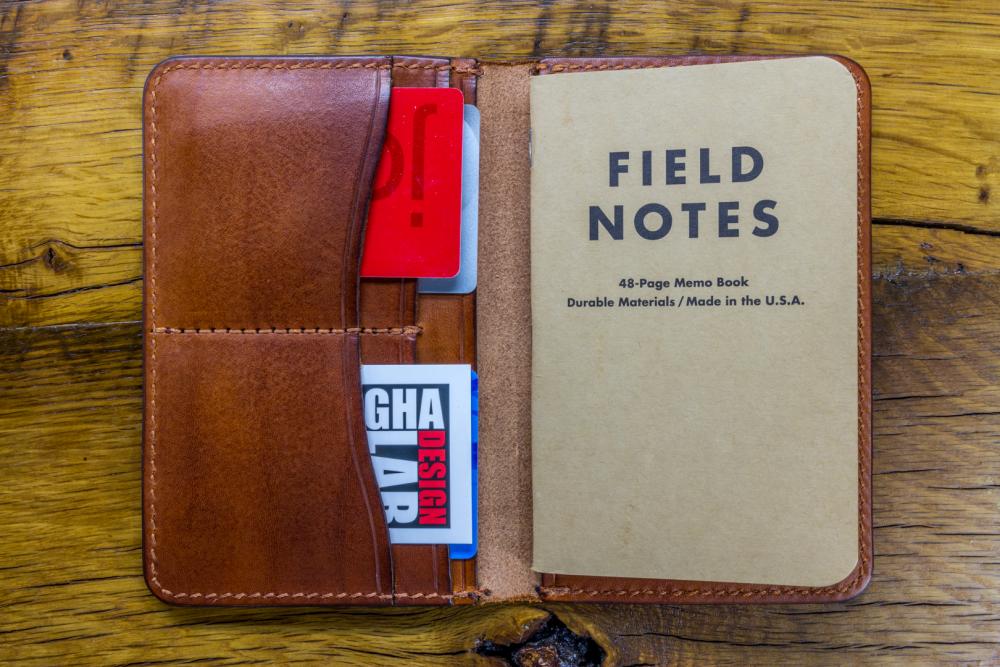

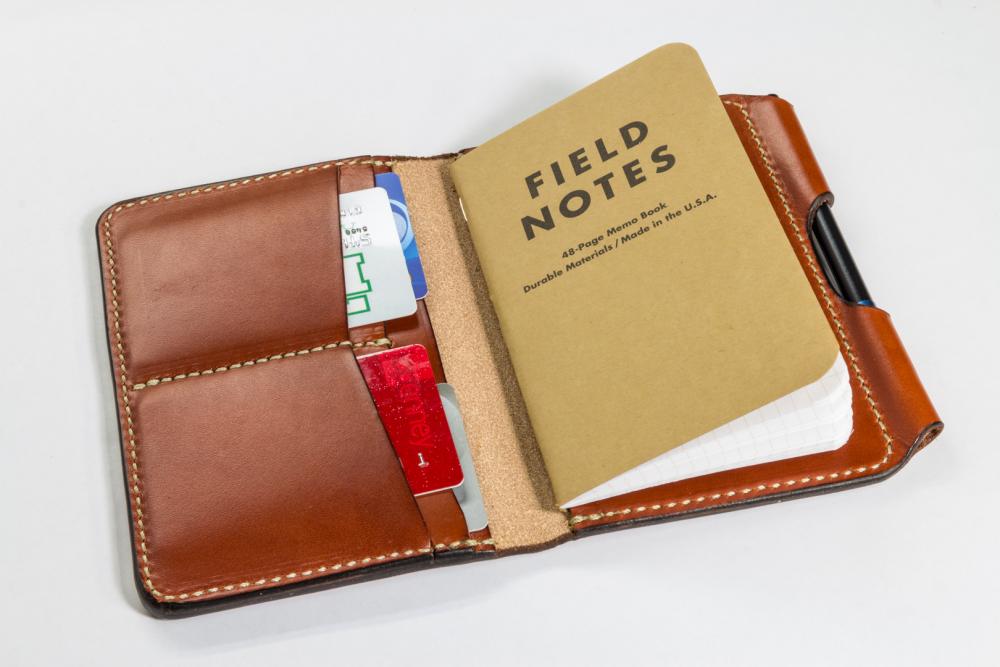

Travel Journal for Field Notes

particle replied to particle's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

If memory serves (I made these over a year ago), the one without a pen holder was made in one evening over the course of about an hour to test my pattern. I'm sure the leather was still damp from the dye when I sewed it. My machine is setup for sewing holsters and since I rarely make anything else, I don't like changing the settings unless absolutely necessary. I should have hand sewn them, but these were all just one-off mock-ups to test patterns prior to going on my website. -

Travel Journal for Field Notes

particle replied to particle's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Here is a couple other variations I made of the same travel journal. The first version had no built-in option for holding a pen. The second one included the pen holder. The third (originally posted) had a locking tab to keep the cover closed when the pen is inserted. -

Sheridan Entry

particle replied to immiketoo's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Great looking holster Michael! -

I used to watch Norm Abrams on The New Yankee Workshop every morning before work while I was getting ready. I knew nothing about woodworking at the time, but nearly everything I know, I learned from watching his TV show (and later reading books & magazines, and more recently YouTube). Sure, I didn't absorb everything he taught, but I picked up bits and pieces, and learned alternate ways to accomplish the same thing - with expensive tools, with cheap tools, with hand tools, etc. Some people are simply thirsty for knowledge. When I first started with leather working, I devoured everything I could find on the internet and watched untold hours of related videos on YouTube. I don't seek them out like I used to, but when I'm trying to learn something new, I welcome those long videos and appreciate the time and energy spent producing them.

-

If the price is right, you can ship it back to Tippmann and they'll refurbish it. If memory serves, I contacted them several years ago and they said it would cost $75-150, depending on what's wrong with it. For what it's worth, the cast iron model is usually more desirable than the newer aluminum model.

-

Without knowing who's pattern you're using, it'll be hard to offer much regarding materials. Regarding the pattern & paper, I like to use heavy card stock. It cuts easily, and is easy enough to trace around & re-print if necessary. Have you tried contacting the pattern maker for more detailed assembly & material questions? Can you post a link to the pattern you purchased? Perhaps if we can see some finished photos we'll better be able to assist you.

-

Historically, no idea, but I've tried the recipe from the first video and like it for outdoor use. Has a pretty strong smell though, and takes a lot of heat to work into the leather. I've also tried 1 part beeswax mixed with 4 parts almond oil. That's nice, with almost no odor of any kind. I touch up my wallet with that. I also tried a mixture of beeswax, cocoa butter, almond oil and castor oil. Smells nice, good on dry skin in the winter, melts into leather with minimal heat.

-

Recent Holster Builds

particle replied to particle's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks y'all! The random carving on the red one is actually an "M" - my boss' last name initial. -

Recent Holster Builds

particle replied to particle's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks Giovanni! -

Recent Holster Builds

particle replied to particle's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks! -

Just wrapped up a few new holsters last weekend. A red & black IWB for my boss' S&W M&Pc, a couple IWBs for a 3" 1911 and Sig 938, and a pancake for my dad's S&W M&P 22 Compact. Forgive me for taking the liberty of photoshopping out a tiny dimple on each of the IWB holsters accidentally pressed into the same spot of each holster from my drying rack... It looked much more obvious in the photos because of the lighting angle. I had every intention of embedding the t-nut between the leather layers, but habit kicked in and I forgot to embed them before assembly. Maybe next time... LOL

-

Need help picking a compressor and airbrush

particle replied to AwenMade's topic in Leatherwork Conversation

I have a Senco PC1010 that I ordered off Amazon and love it. It's very quiet, though not as quiet as a dedicated airbrush compressor. But I can still air up car tires, drive finish nailers, blow stuff off, etc. If noise is a concern, most of the pancake compressors you mentioned probably won't fit the bill. -

Recent Holster Builds

particle replied to particle's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks for the compliments everyone! -

Recent Holster Builds

particle replied to particle's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I use pretty basic stuff - Tandy wood burnisher for initial shaping and contours, bone folder for details and flattening out the flat areas, and a wooden clay modeling stick for the interior burnishing. -

My site is setup to take payment at the time the order is placed. I used to collect orders via a form on my site, then request payment just prior to starting the order. What I found was loads of people forgot they placed the order by the time I got to them in the queue, and it would usually take people days or weeks to reply, if ever. Or people would buy a gun, order a holster, then realize they don't really like the gun and trade it off, but forget they ordered a holster. Meaning, I was jumping all over the place in the queue to finish orders on an as-responded basis, instead of as-ordered basis. My wife does most of my order management, leaving me time to focus on my 8-5 job (plus 2+ hours of drive time to & from work), family time (wife & 3 young kids), and shop time. To simplify her life, she asked that I start collecting money up front. My order cancellations went from 2 or 3 per batch, to 2 or 3 per YEAR. I'm one of the 16-18 week lead time (Elvis wanna'be) guys. Not because I think my holsters are prized unicorns, but because people keep ordering holsters from me and I simply don't have enough hours in the day to keep up. The only solution is to increase the lead times (and/or raise prices, which I really need to do anyway), which has helped slow down new orders considerably. However, people keep ordering. I could close my site, but that would close down my other products (digital products included), and that would be unwise as I've seen others do that and have a difficult time recovering and getting new orders back to the frequency level from prior to shutting things down. I could mark my hand-made items as out-of stock with no back-order options, but then I have to try and forecast when I'll get my lead times down and guess when I should activate my hand-made products again and just hope that new orders start rolling in so I have orders to work on when I'm ready for the next batch... Truthfully, I'm trying to slow down new hand-made physical product orders. I may not actually take 16-18 weeks to finish an order (although I am right now because I got absolutely slammed in December 2015 with new orders), and my lead time is normally a little shorter (8-12 weeks is more normal), but it gives me a little flexibility to focus on the things I'd much rather be doing (most notably, spending time with family), which is building my digital product library (residual income products like patterns, tutorial videos, etc). I can understand not wanting to wait months to receive your item. Good thing there's so many makers out there to choose from. But I'm humbled and grateful that anyone would actually wait that long for MY products.

-

Another red handbag

particle replied to olenawills's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Wow! I'm certainly impressed. Very nice work! -

Pancake - Ruger Super Blackhawk

particle replied to particle's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks Josh! Herman Oak, Fiebing's Pro Oil Saddle Tan, Neetsfoot Oil. -

I hate doing revolver holsters, but every now and then I'll slip one in if I have access to the correct dummy gun or actual gun. This one came out okay I think. The customer was pleased with it, which is what matters most. I don't have any pics with the gun in the holster, unfortunately. Nor do I have any pics from the back.

-

Travel Journal for Field Notes

particle replied to particle's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I'm not sure I want to tell you if you're going to give the patterns away for free... http://www.adamsleatherworks.com/shop/pattern-leather-travel-journal-pen-lock/